Hydrophobic porous MXene membrane as well as preparation method and application thereof

A hydrophobic and porous substrate technology, applied in the field of membrane separation, can solve the problems of low permeation flux, limited application, etc., to achieve excellent salt rejection, promote transfer, and improve anti-moisture and anti-fouling ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

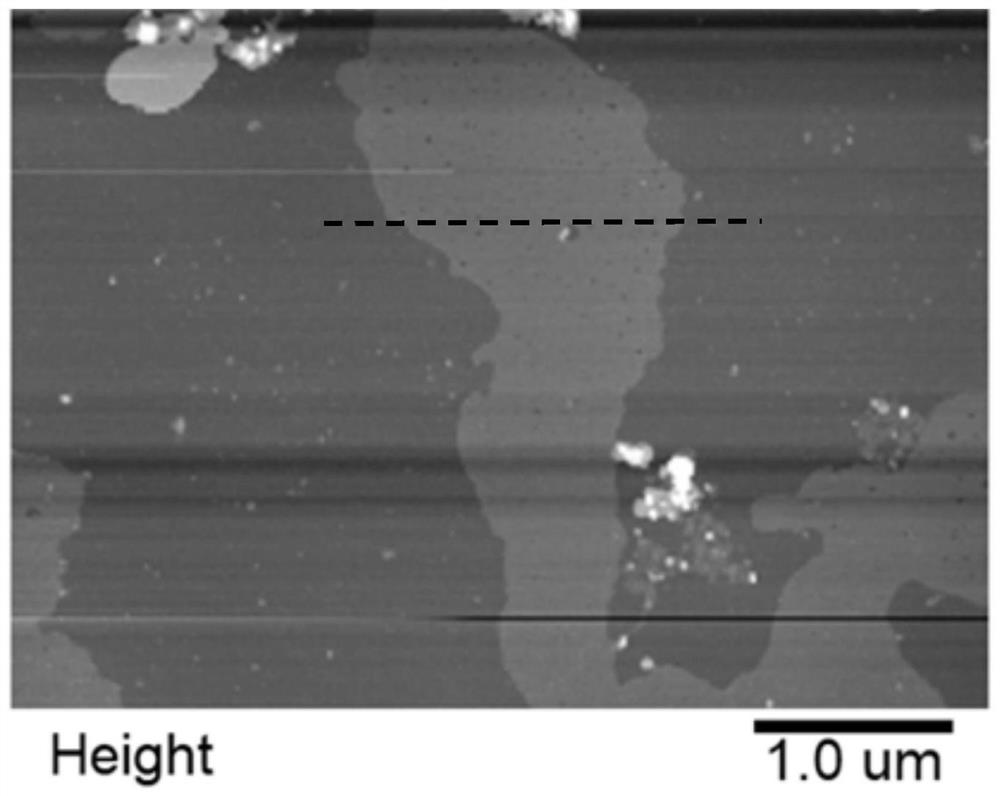

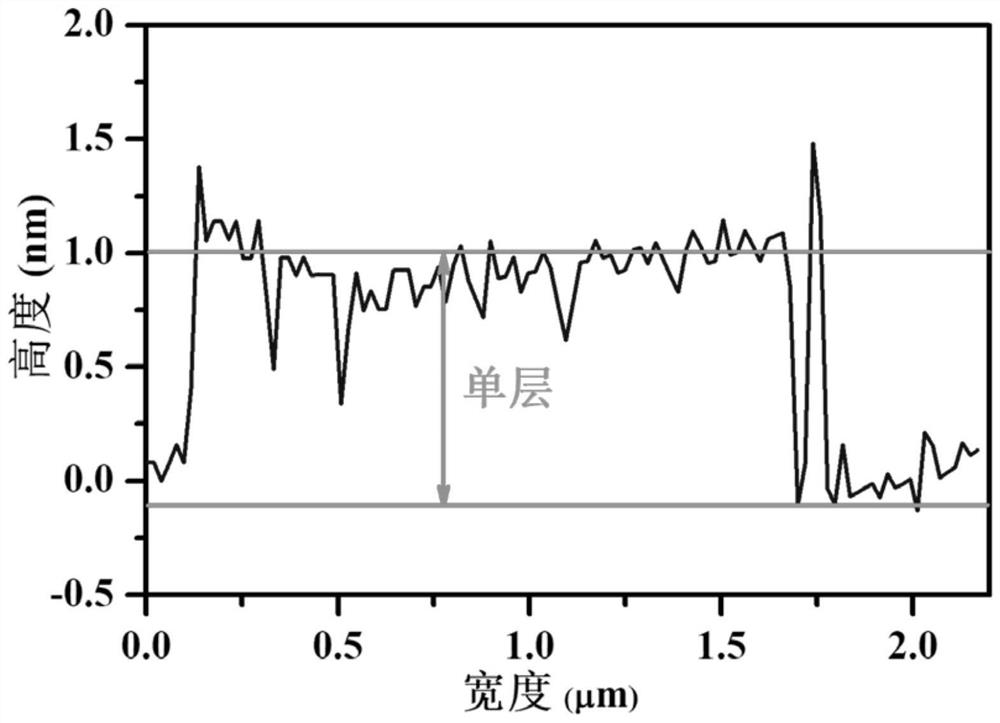

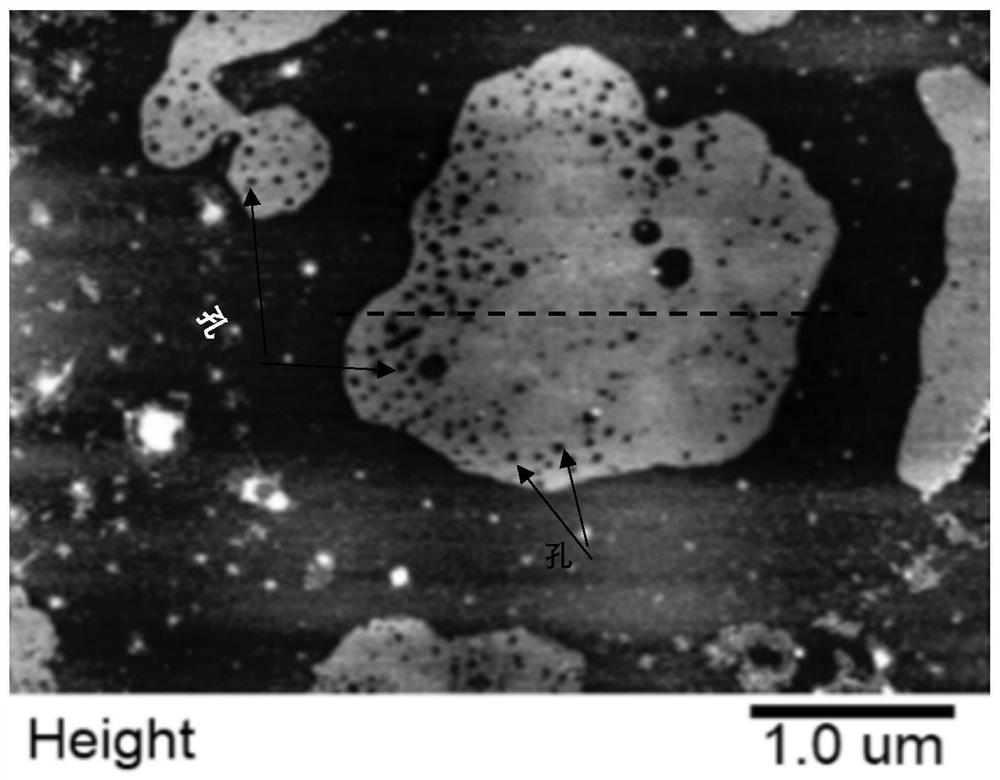

Image

Examples

Embodiment 1

[0038] A kind of preparation of hydrophobic porous MXene film, comprises the following steps:

[0039] (1) 1 g of LiF was dissolved in 20 mL of 6M HCl, and the mixture was rapidly stirred at room temperature for 5 minutes. Then, within 5 minutes, 1 g Ti 3 AlC 2Add slowly to LiF / HCl mixture to avoid bumping. Afterwards, stirring was continued at 35°C for 24 hours. The resulting product was washed with deionized water and centrifuged at 3500 rpm for 5 minutes, which was repeated several times until the pH of the supernatant was >6. Then, the precipitate was dissolved in 100 mL of deionized water and ultrasonically dispersed for 30 min to delaminate the MXene flakes. Subsequently, the Ti 3 C 2 T x The solution was centrifuged at 3500rpm for 10 minutes, repeated several times until there was no sediment in the centrifuge tube. Collect the light green supernatant, i.e. the colloidal solution of MXene.

[0040] (2) First prepare a hydrolysis solution of HTEOS composed of 0....

Embodiment 2

[0046] A kind of preparation of hydrophobic porous MXene film, comprises the following steps:

[0047] (1) 2g LiF was dissolved in 40mL of 6M HCl, and the mixture was rapidly stirred at room temperature for 10 minutes. Then, 1g Ti 3 AlC 2 Add slowly to LiF / HCl mixture to avoid bumping. Afterwards, stirring was continued for 48 hours at 25°C. The resulting product was washed with deionized water and centrifuged at 5000 rpm for 10 minutes, which was repeated several times until the pH of the supernatant was >6. Then, the precipitate was dissolved in 100 mL of deionized water and ultrasonically dispersed for 60 min to delaminate the MXene flakes. Subsequently, the Ti 3 C 2 T x The solution was centrifuged at 5000rpm for 20 minutes, repeated several times until there was no sediment in the centrifuge tube. Collect the light green supernatant, i.e. the suspension of MXene.

[0048] (2) Firstly, a hydrolysis solution of HTEOS composed of 1 vol% acetic acid, 5 vol% n-hexadec...

Embodiment 3

[0054] A kind of preparation of hydrophobic porous MXene film, comprises the following steps:

[0055] (1) 4g LiF was dissolved in 80mL of 6M HCl, and the mixture was rapidly stirred at room temperature for 15 minutes. Then, 1g Ti 3 AlC 2 Add slowly to LiF / HCl mixture to avoid bumping. Afterwards, stirring was continued at 40°C for 24 hours. The resulting product was washed with deionized water and centrifuged at 6000 rpm for 5 minutes, which was repeated several times until the pH of the supernatant was >6. Then, the precipitate was dissolved in 100 mL of deionized water and ultrasonically dispersed for 30 min to delaminate the MXene flakes. Subsequently, the Ti 3 C 2 T x The solution was centrifuged at 6000rpm for 30 minutes, repeated several times until there was no sediment in the centrifuge tube. Collect the light green supernatant, i.e. the suspension of MXene.

[0056] (2) Firstly, a hydrolysis solution of HTEOS composed of 5 vol% acetic acid, 8 vol% n-hexadecy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com