Collecting agent for copper-molybdenum separation, flotation agent and flotation method

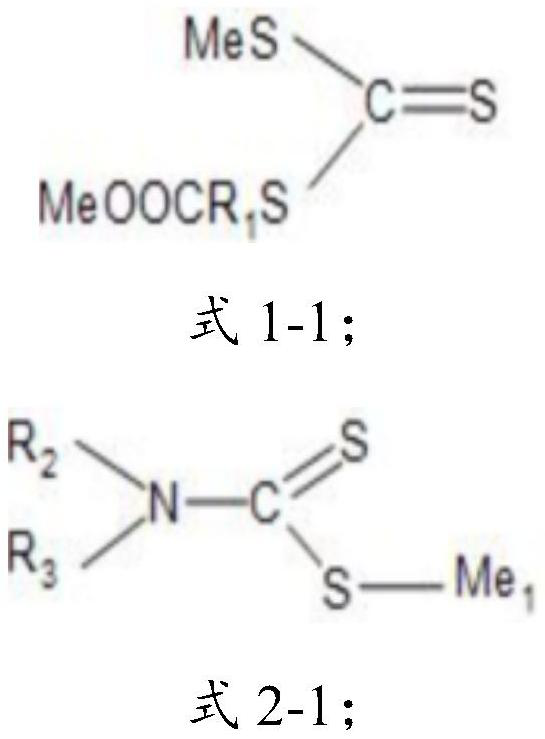

The technology of collector and flotation agent is applied in the field of collectors for separation of copper and molybdenum, which can solve the problems of poor selectivity and large required amount, and achieve improved effect, strong sorting and collecting performance, and strong trapping. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0040] 1. Preparation of flotation agents, including the following steps:

[0041] (1) Component, 20 parts by weight 2-2 shown, 20 parts by weight of the group 2-2, and 20 parts by weight of the group, 10 parts by weight Division (pine alcohol oil) is added to 200 ml of capacity bottles;

[0042] (2) Place the capacity bottle of step (1) in a beaker having a 50 ° C constant temperature water bath, and then the material in the mechanical agitator is stirred in the capacity bottle for 10 hours to obtain a flotation agent, spare.

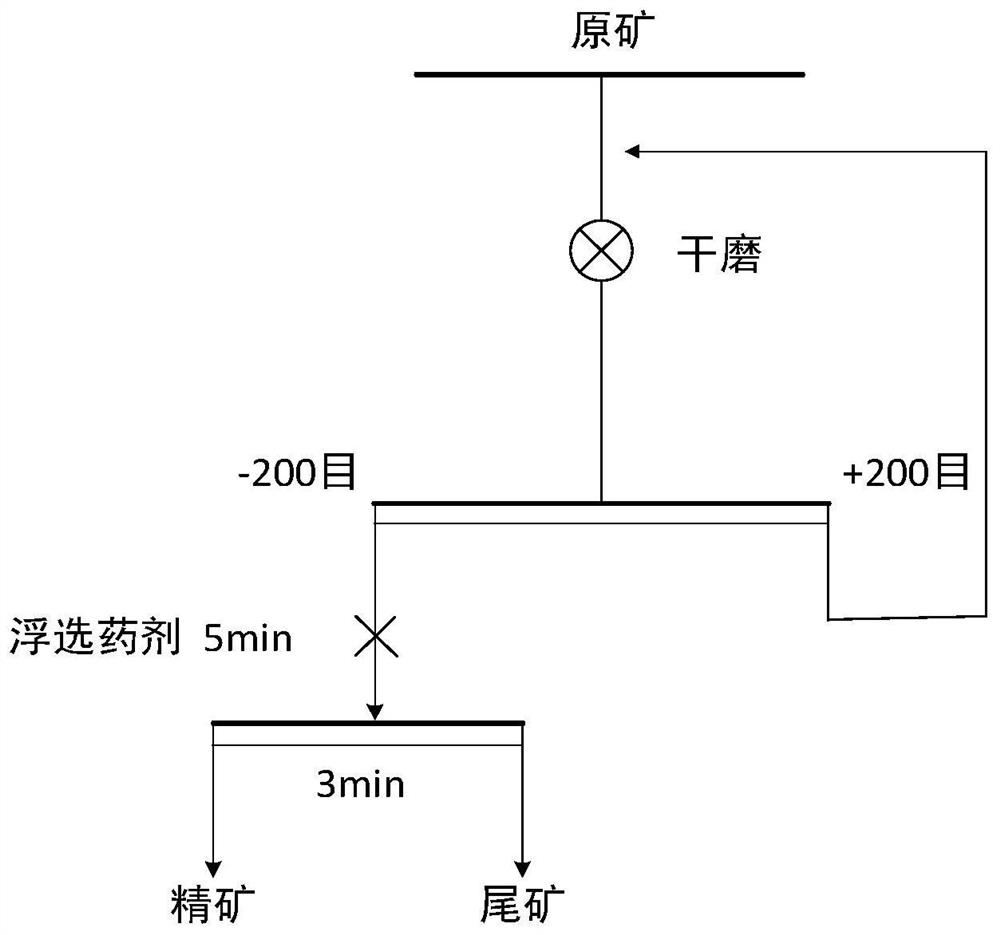

[0043] 2, flotation test process: reference figure 1 To put 2 G brass mine pure minerals (from Yunnan Yunxian, the same below), put the appropriate amount of deionized water, stirred for 3 minutes, so that the pulp is mixed, and the floating of the present embodiment prepared in this example. Choose a pharmaceutically solve, stirred with a mixture of 5 minutes, scrape, scrape for 3 minutes, and dry the concentrate and tailings separately, calculate the rec...

no. 2 example

[0054] 1. Preparation of flotation agents, including the following steps:

[0055] (1) Component, 20 parts by weight 2-2 shown, 20 parts by weight of the group 2-2, and 20 parts by weight of the group, 10 parts by weight Division (pine alcohol oil) is added to 200 ml of capacity bottles;

[0056] (2) Place the capacity bottle of step (1) in a beaker having a 50 ° C constant temperature water bath, and then the material in the mechanical agitator is stirred in the capacity bottle for 10 hours to obtain a flotation agent, spare.

[0057] 2, flotation test process: reference figure 1 The 2 g of molybdenum ore pure mineral (from Myanmar) was placed in a 40 ml flotation tank, and the appropriate amount of deionized water was added, stirred for 3 minutes, and the pulp was stirred evenly, and the flotation agent prepared by the present embodiment (500 g of addition is 500 g). T), stirred with a stirring for 5 minutes, scraping, scraping for 3 minutes, drying the concentrate and tailings ...

no. 3 example

[0067] 1. Preparation of flotation agents, including the following steps:

[0068] (1) Component, 20 parts by weight 2-2 shown, 20 parts by weight of the group 2-2, and 20 parts by weight of the group, 10 parts by weight Division (pine alcohol oil) is added to 200 ml of capacity bottles;

[0069] (2) Place the capacity bottle of step (1) in a beaker having a 50 ° C constant temperature water bath, and then the material in the mechanical agitator is stirred in the capacity bottle for 10 hours to obtain a flotation agent, spare.

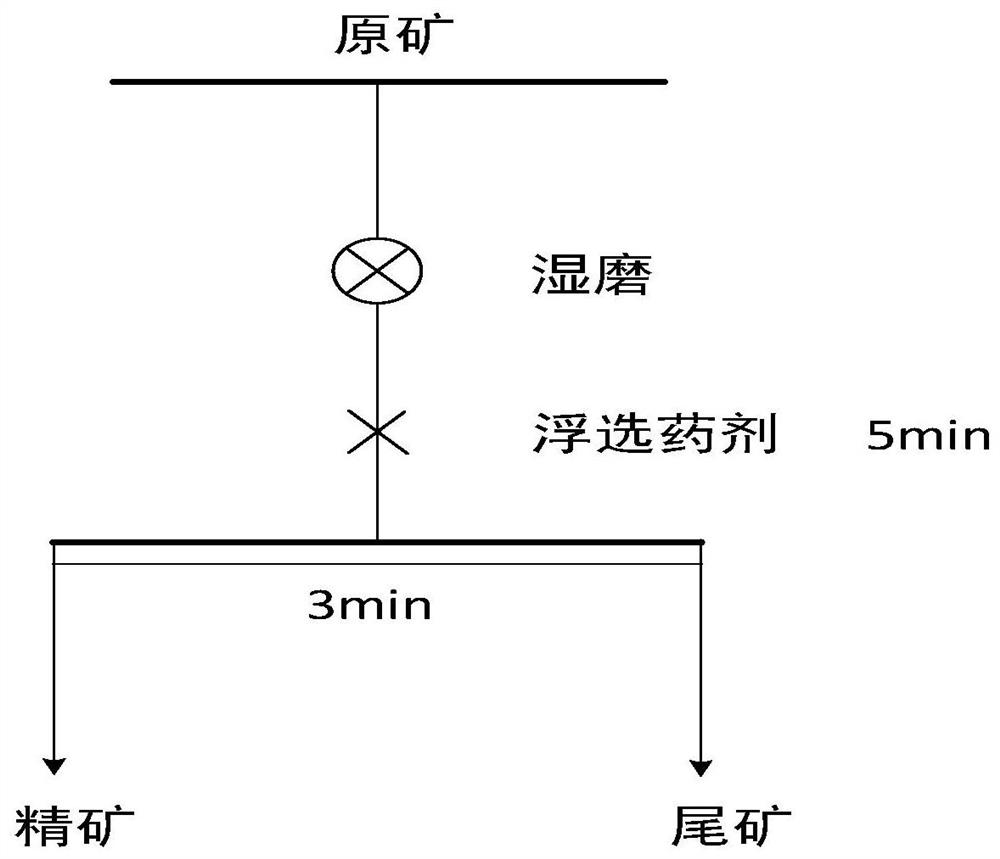

[0070] 2, flotation test process: reference figure 2 The 500g actual mine (0.46% copper) is placed in a 1.5L flotation tank, and the appropriate amount of deionized water is added, stirred for 3 minutes, and the mixing of the slurry is mixed, and the present embodiment is prepared. Flotation agent for flotation, stirred for 5 minutes, scraping, scraping for 3 minutes, drying the concentrate and tailings separately, calculating the recovery rate. Among them...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com