Friction welding method with interlayer material added

A friction welding and intermediate layer technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of low connection strength, affecting joint performance, poor plasticity, etc., and achieve the effect of easier softening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Embodiment 1: In this embodiment, the middle layer material is added on the end face of the workpiece to be welded by laser additive manufacturing.

[0065] In the friction welding method of the embodiment of the present invention, the size of the workpiece 1 to be welded is 12.5mm×25mm×50mm, and 12.5mm×25mm is used as the welding end of the workpiece 1 to be welded.

[0066] Step 1: Perform sandblasting pretreatment on the surfaces of the two workpieces 1 to be welded.

[0067] Step 2: Wipe the surfaces of the two workpieces 1 to be welded with alcohol to remove impurities on the surfaces of the workpieces 1 to be welded.

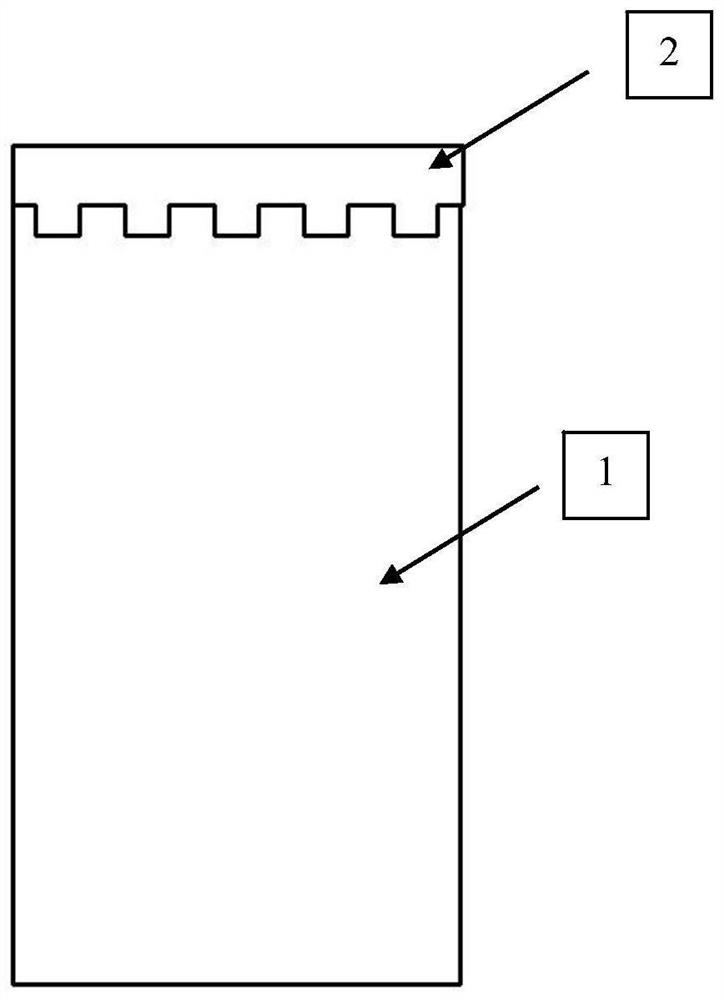

[0068] Step 3: The welding ends of the two workpieces 1 to be welded in step 2 are stacked with the original intermediate layer 2 by the method of laser additive manufacturing, and the material of the laser additive is Ti 2 AlNb or titanium alloy powder. The thickness H of the raw intermediate layer 2 = 8 mm.

[0069] Step 4: Machining the origin...

Embodiment 2

[0073] Embodiment 2: In this embodiment, the intermediate layer material added on the end surface of the workpiece to be welded is mechanically fixed.

[0074] In the friction welding method of the embodiment of the present invention, the size of the workpiece 1 to be welded is 75mm×20mm×130mm, and 75mm×20mm is used as the welding end of the workpiece 1 to be welded.

[0075] Step 1: Machining grooves on one end of the two workpieces 1 to be welded, correspondingly setting a boss on the workpiece 2 corresponding to the workpiece 1 to be welded to ensure that the workpiece 1 to be welded and the original intermediate layer can form a good fixation . Wherein the height of the boss and the depth of the groove are both no more than 5mm.

[0076] Step 2: install the workpiece 1 to be welded on the vibrating fixture and the upsetting fixture on the linear friction welding machine respectively, and install the original intermediate layer 2 and the workpiece 1 to be welded together. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com