Pervaporation membrane with specific function and preparation method and application thereof

A pervaporation membrane and a technology with specific functions, which is applied in the field of pervaporation membrane and its preparation, can solve the problems that the hydrophobicity is difficult to meet the efficient recovery of organic matter in the pervaporation membrane, increase the difficulty of operation, and microbial adhesion, etc., to achieve enhanced anti-biological pollution performance, Improvement of reactivity, hydrophobicity and anti-fouling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0054] As mentioned above, in the traditional polymer film preparation process, it is inevitable to use organic solvents to dissolve polymers, and solvent volatilization will increase the difficulty of actual operation and cause environmental pollution; at the same time, traditional polymer films due to their own material properties Limitations, hydrophobicity is difficult to meet the requirements of pervaporation membrane for efficient recovery of organic matter, and high membrane surface free energy is easy to cause microbial adhesion (membrane fouling).

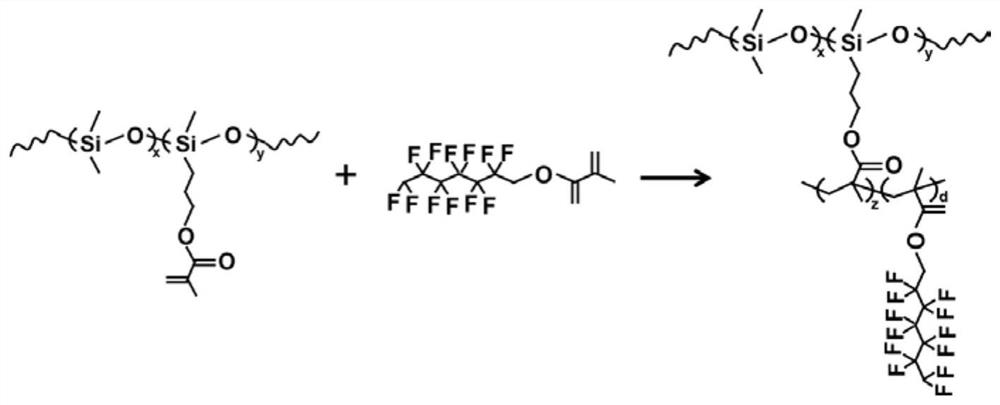

[0055] In view of this, the inventors have conducted a lot of research on hydrophobic pervaporation membranes. The inventors have found that using fluorine-containing small molecules as light-responsive diluting monomers to replace traditional organic solvents can (1) reduce the membrane liquid The viscosity of the polymer chain can alleviate the excessive packing of the polymer chain, increase the collision rate between mo...

Embodiment 1

[0106] (1) Preparation of photoresponsive polydimethylsiloxane: 11g of hydroxyl-terminated polydimethylsiloxane (hydroxyl-terminated polydimethylsiloxane, molecular weight 50,000), 2g of modifier γ-methicone Acryloxypropyl trimethoxysilane (equivalent to 18wt% of polysiloxane), 0.2g catalyst dibutyltin dilaurate mixed (equivalent to 1.8wt% of polysiloxane), stirred by 600rpm mechanical Mix well; degassing to obtain polydimethylsiloxane with photoresponsiveness.

[0107] (2) Preparation of casting solution: Take 5g of the above photoresponsive polydimethylsiloxane, add 2g of dodecafluoroheptyl methacrylate (photoresponsive polysiloxane and photoresponsive diluent monomer) The mass ratio is 2.5:1) and 1wt% photoinitiator 2-hydroxyl-2-methylpropiophenone (1wt% equivalent to photoresponsive diluting monomer and photoresponsive polysiloxane total amount), 1000rpm mechanical stirring is sufficient Mix to obtain casting solution.

[0108] (3) Scratch film: after defoaming the above...

Embodiment 2

[0112] (1) Preparation of photoresponsive polydimethylsiloxane: 5g hydroxyl-terminated polydimethylsiloxane (molecular weight 20000), 1g modifier 3-methacryloxypropylmethyl dimethicone Methoxysilane (equivalent to 20wt% of polysiloxane), 0.1g catalyst dibutyltin dilaurate mixed (equivalent to 2wt% of polysiloxane), fully mixed by 600rpm mechanical stirring; Responsive polydimethylsiloxane.

[0113] (2) Preparation of casting solution: take 5g of the above-mentioned photoresponsive polydimethylsiloxane, add 5g of dodecafluorohexyl methacrylate (the mass of photoresponsive polysiloxane and photoresponsive diluent monomer The ratio is 1:1) and 3wt% photoinitiator diphenyl-(2,4,6-trimethylbenzoyl) oxyphosphine (equivalent to the total amount of photoresponsive diluent monomer and photoresponsive polysiloxane 3wt%), fully mixed with 1000rpm mechanical stirring, to obtain the casting solution.

[0114] (3) Scratch film: after defoaming the above-mentioned casting solution, apply f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com