Continuous solid-phase condensation polymerization method for producing high-temperature-resistant nylon

A technology of solid-phase polycondensation and high temperature resistance, which is applied in the field of continuous solid-phase polycondensation for the production of high-temperature-resistant nylon, and can solve problems such as affecting product performance and appearance, low production efficiency, and affecting production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

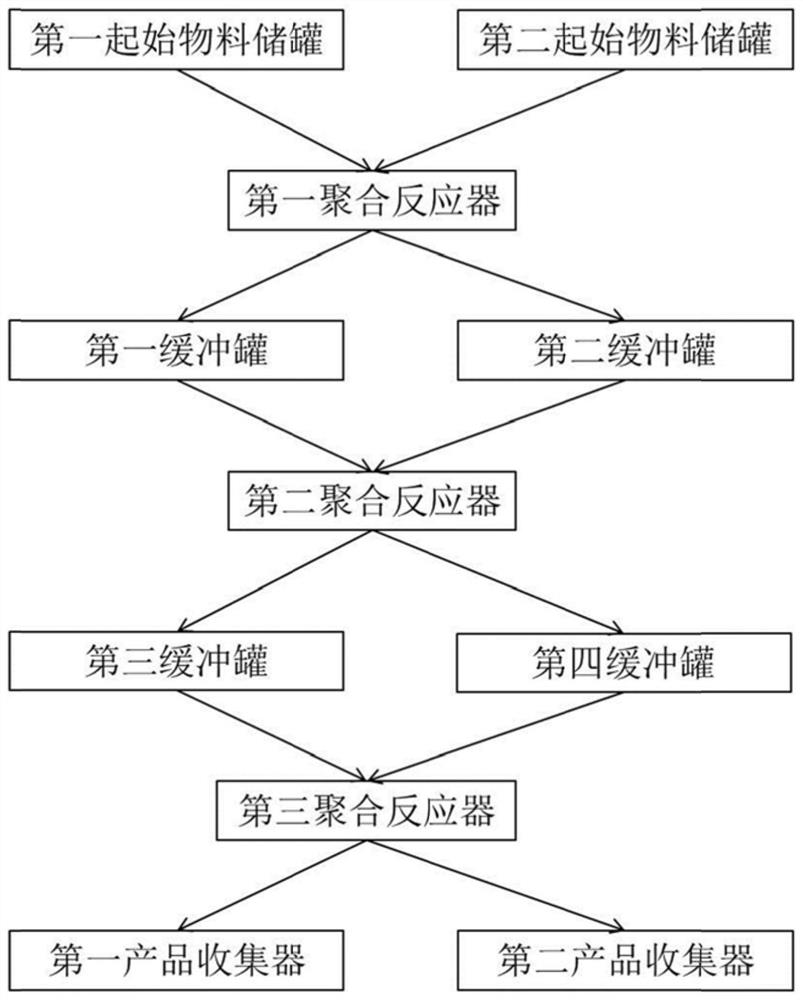

[0044] The continuous solid-state polycondensation method for producing high-temperature-resistant nylon in this embodiment is illustrated by taking the synthesis of high-temperature-resistant nylon PA12T as an example, including the following steps:

[0045] 1) Solid-phase pre-polymerization stage: 10kg nylon 12T salt (water content is 10%), 30g catalyst sodium hypophosphite and 20g antioxidant s9228 are added in the first and second starting material storage tanks and stirred evenly, sealed, and used N 2 The entire polymerization system was replaced with gas three times and inflated to a pressure of 0.05 MPa. Turn on the heating system of the polymerization reactor, the buffer tank and the product collector, make it rise to the predetermined temperature and stabilize it for 1h.

[0046] The system connection was switched to the first starting material storage tank, the first polymerization reactor and the first buffer tank, and the remaining system connections of the starti...

Embodiment 2

[0050] The continuous solid-state polycondensation method for producing high-temperature-resistant nylon of the present embodiment, synthesizing high-temperature-resistant nylon PA6T / 66, comprises the following steps:

[0051] 1) Solid phase prepolymerization stage: 10kg nylon 6T / 66 salt (water content is 8%; the molar ratio of nylon 6T salt and nylon 66 salt is 55:45), 30g catalyst sodium hypophosphite and 20g antioxidant s9228 Add the first and second starting material storage tanks and stir evenly, seal, and use CO 2 The entire polymerization system was replaced with gas three times and inflated to a pressure of 0.05 MPa. Turn on the heating system of the polymerization reactor, the buffer tank and the product collector, make it rise to the predetermined temperature and stabilize it for 1h.

[0052] The system connection was switched to the first starting material storage tank, the first polymerization reactor and the first buffer tank, and the remaining system connections...

Embodiment 3

[0056] The continuous solid-state polycondensation method for producing high-temperature-resistant nylon of the present embodiment, synthesizing high-temperature-resistant nylon PA12T / 6T, comprises the following steps:

[0057] 1) Solid phase prepolymerization stage: 10kg nylon 12T / 6T salt (water content is 12%; the molar ratio of nylon 12T salt to nylon 6T salt is 6:4), 30g catalyst sodium hypophosphite and 20g antioxidant s9228 Add the first and second starting material storage tanks and stir evenly, seal, and use CO 2 The entire polymerization system was replaced with gas three times and inflated to a pressure of 0.05 MPa. Turn on the heating system of the polymerization reactor, the buffer tank and the product collector, make it rise to the predetermined temperature and stabilize it for 1h.

[0058] The system connection was switched to the first starting material storage tank, the first polymerization reactor and the first buffer tank, and the remaining system connection...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com