Ecological degradable plastic mulching film and preparation method thereof

A technology for degrading plastics and mulches, applied in botany equipment and methods, horticulture, plant protection covers, etc., can solve the threat of sustainable use of cultivated land, environmental problems and other issues, and achieve thermal decomposition, simple preparation methods, and improved tensile strength intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

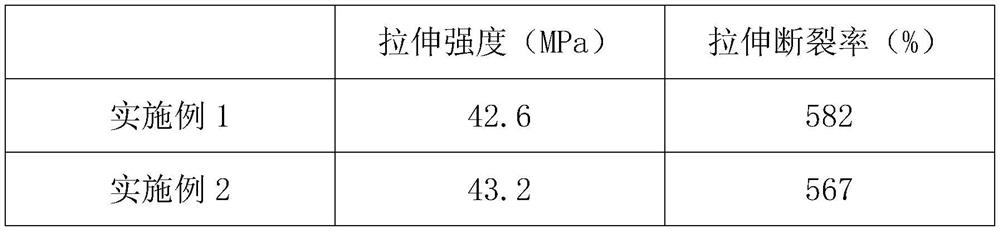

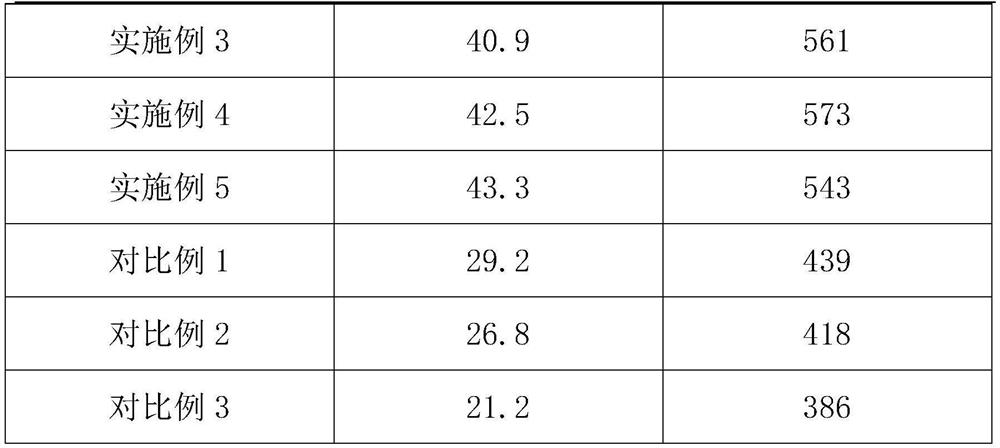

Examples

Embodiment 1

[0022] In Example 1, an ecological degradation plastic film, composed of a weight of the following weight: 80 parts of linear low density polyethylene, 10 parts of high density polyethylene, 20 starch, 1 plasticizer and environmentally friendly deworm filler 12 Part.

[0023] Further, the environmentally-deridated filler consists of 40 parts of the following weight: 40 parts of rice husk, 20 copies of calcium carbonate, 50 water and 5 parts of plant source.

[0024] Further, the preparation method of the environmentally-inductorfi filler includes the following steps: mix the rice husk and calcium carbonate, ground powder, then add water and stir well, stand for 12 h at room temperature, after standing, placed in a high temperature furnace, Under the nitrogen atmosphere, calcination of 0.5 h at a temperature of 880 ° C, after cooling, adding a plant source insect agent, mix uniform, disrupted into powder to obtain an environmentally friendly deworm filler.

[0025] Further, the pla...

Embodiment 2

[0033] In Example 2, an ecological degradation plastic film film, consisting of a weight of the following weight: 90 parts of linear low density polyethylene, 15 parts of high density polyethylene, 25 starch, 3 plasticizers and environmentally friendly worms 18 Part.

[0034] Further, the environmentally-inductorous filler consists of 50 parts of the following weight: 50 parts of rice husk, 25 calcium carbonate, and 9 water in water and the plant source.

[0035] Further, the preparation method of the environmentally-induced plug-in filler includes the steps of mixing the rice husk and calcium carbonate, polishing powder, then add water and stir evenly, standing for 24 h at room temperature, after standing, placed in a high temperature furnace, At a temperature of the nitrogen atmosphere, 1 h is calcined at a temperature of 900 ° C, after cooling, the plant source insect agent is added, mixed uniform, broken into powder, and obtain an environmentally friendly deworm filler.

[003...

Embodiment 3

[0044] In Example 3, an ecological degradation plastic film film consists of 85 parts of the following weight: 12 parts of linear low density polyethylene, 12 parts of high density polyethylene, 2 starch, 2 plasticizers and environmentally friendly worms 16 Part.

[0045] Further, the environmentally-inductive filler consists of 45 raw materials of the following weight: 2 of rice shells, 22 calcium carbonate, and 7 water in water and 7 parts of plant source.

[0046] Further, the preparation method of the environmentally-inductorfi filler includes the following steps: mix the rice husk and calcium carbonate, ground powder, then add water and stir well, stand for 18h at room temperature, after standing, placed in a high temperature furnace, At a temperature of the nitrogen atmosphere, 0.5 h was calcined at a temperature of 890 ° C, after cooling, the plant source insectic agent was added, mixed uniform, crushed into powder to obtain an environmentally friendly deworm filler.

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com