Polarity surface distinguishing method for aluminum nitride single crystal polished wafer (0001) surface

A technology of aluminum nitride and polishing sheet, applied in chemical method analysis, chemical instrument and method, crystal growth and other directions, to achieve the effect of high efficiency, small damage and remarkable effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

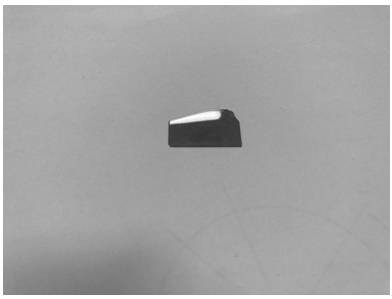

Image

Examples

Embodiment 1

[0014] Example 1, a method for distinguishing polar planes on the (0001) plane of an aluminum nitride single crystal polished wafer, the specific steps are as follows:

[0015] 1). Preparation of corrosion solution

[0016] Add 100ml of deionized water to a 200ml beaker, and then add 5ml of ethylamine and 15ml of 6508 isopropanolamide in turn, and stir it with a glass rod to mix quickly and evenly.

[0017] 2). Heating of corrosive liquid

[0018] Place the beaker containing the corrosive solution on the heating platform, adjust the temperature of the heating platform to 60°C, and measure the temperature with a temperature gun.

[0019] 3). Corrosion of polishing sheet

[0020] After the temperature of the etching solution rises to 60°C, use plastic tweezers to hold the (0001) surface aluminum nitride single crystal polishing wafer to be distinguished and place it in the etching solution to ensure that the front and back sides of the wafer are fully in contact with the etchi...

Embodiment 2

[0023] Example 2, a method for distinguishing polar planes on the (0001) plane of an aluminum nitride single crystal polished wafer, the specific steps are as follows:

[0024] 1). Preparation of corrosion solution

[0025] Add 100ml of deionized water to a 200ml beaker, and then add 10ml of ethylamine and 30ml of 6508 isopropanolamide in turn, and stir it with a glass rod to mix quickly and evenly.

[0026] 2). Heating of corrosive liquid

[0027] Place the beaker containing the corrosive solution on the heating platform, adjust the temperature of the heating platform to 70°C, and measure the temperature with a temperature gun.

[0028] 3). Corrosion of polishing sheet

[0029] After the temperature of the etching solution rises to 70°C, use plastic tweezers to hold the (0001) surface aluminum nitride single crystal polished wafer to be distinguished and place it in the etching solution to ensure that the front and back sides of the wafer are in full contact with the etchin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com