Method for improving electrochemical activity of negative electrode of all-vanadium redox flow battery

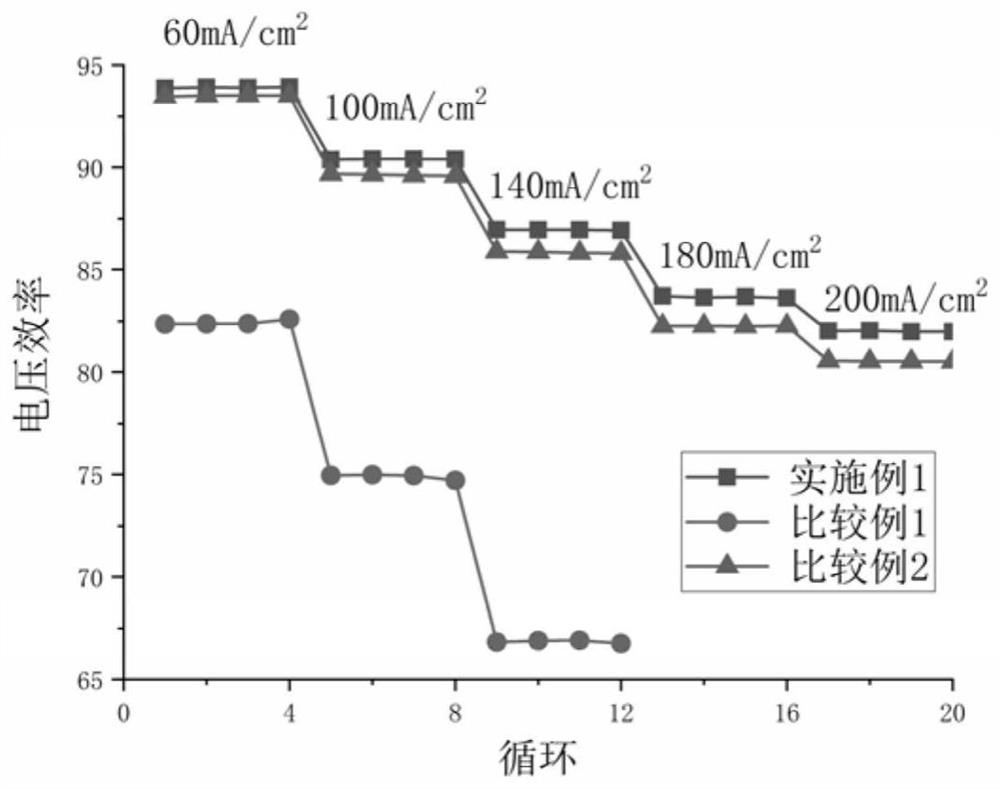

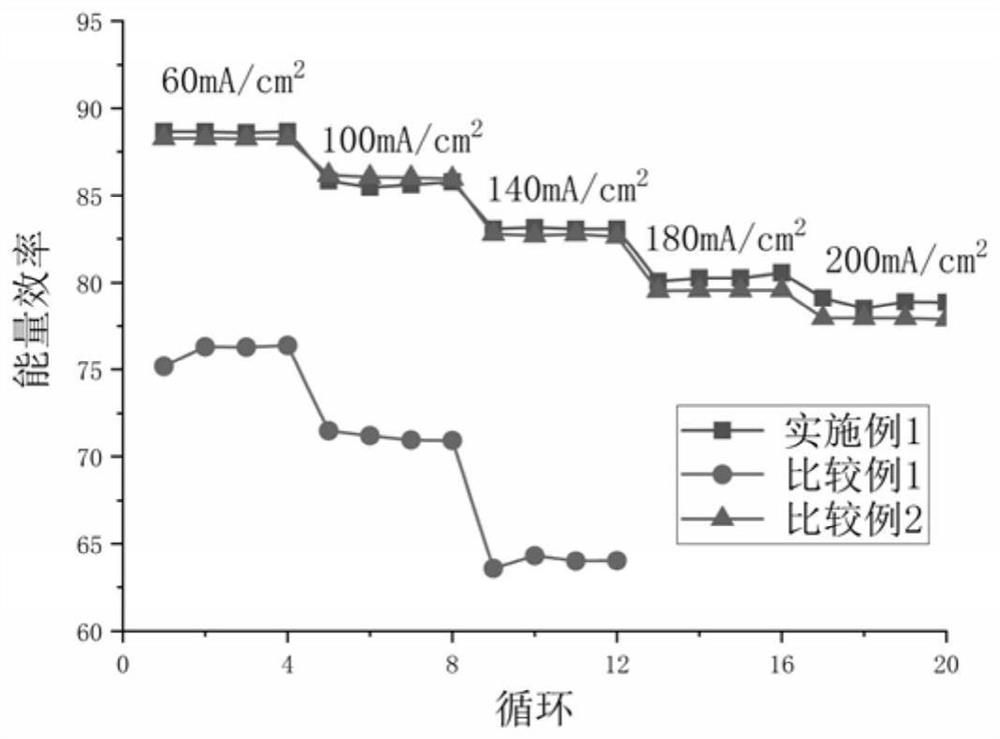

An all-vanadium redox flow battery and a negative electrode electrolyte technology are applied in the all-vanadium redox flow energy storage battery, in the field of improving the electrochemical activity of the negative electrode of the all-vanadium redox flow battery, and can solve the problems of increasing production costs, increasing electrode material preparation steps, and the like. , to achieve the effect of improving conductivity, improving electrochemical activity and electrochemical reversibility, and improving voltage efficiency and energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The traditional all-vanadium redox flow battery positive electrolyte is 1.5M VO 2+ 3M H 2 SO 4 solution, the negative electrode electrolyte is 1.5MV 3+ 3M H 2 SO 4 solution. Weigh a certain amount of AgNO 3 After making an aqueous solution, add it to the negative electrode electrolyte, ultrasonically disperse it for 30 minutes to completely dissolve it, and Ag + The concentration is controlled at 0.01M.

Embodiment 2

[0030] The traditional all-vanadium redox flow battery positive electrolyte is 1.5M VO 2+ 3M H 2 SO 4 solution, the negative electrode electrolyte is 1.5MV 3+ 3M H 2 SO 4 solution. Weigh a certain amount of Ag 2 SO 4 After making a solution, add it to the negative electrode electrolyte, ultrasonically disperse it for 30 minutes to completely dissolve it, and the Ag + The concentration is controlled at 0.005M.

[0031] The single cell assembly evaluation conditions are the same as in Example 1, except that the difference from Example 1 is that the all-vanadium redox flow battery using the negative electrolyte of this example has a current density of 100mA / cm 2 , the voltage efficiency and energy efficiency were 89.8% and 84.6%, respectively, significantly improved compared with the standard negative electrolyte.

Embodiment 3

[0033] The traditional all-vanadium redox flow battery positive electrolyte is 1.5M VO 2+ 3M H 2 SO 4solution, the negative electrode electrolyte is 1.5MV 3+ 3M H 2 SO 4 solution. Weigh a certain amount of AgNO 3 After making a solution, add it to the negative electrode electrolyte, and ultrasonically disperse it for 60 minutes to completely dissolve it. + The concentration is controlled at 0.001M.

[0034] The single cell assembly evaluation conditions are the same as in Example 1, except that the difference from Example 1 is that the all-vanadium redox flow battery using the negative electrolyte of this example has a current density of 100mA / cm 2 , the voltage efficiency and energy efficiency were 89.5% and 84.3%, respectively, which were significantly improved compared with the comparative example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| voltage efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com