Lithium ion battery diaphragm material and preparation method thereof

A technology for lithium ion batteries and separator materials, which is applied in the field of lithium ion battery separator materials and their preparation, can solve the problems of short life and poor safety of lithium ion batteries, and achieves improved thermal stability, low manufacturing cost, and rate performance. boosted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

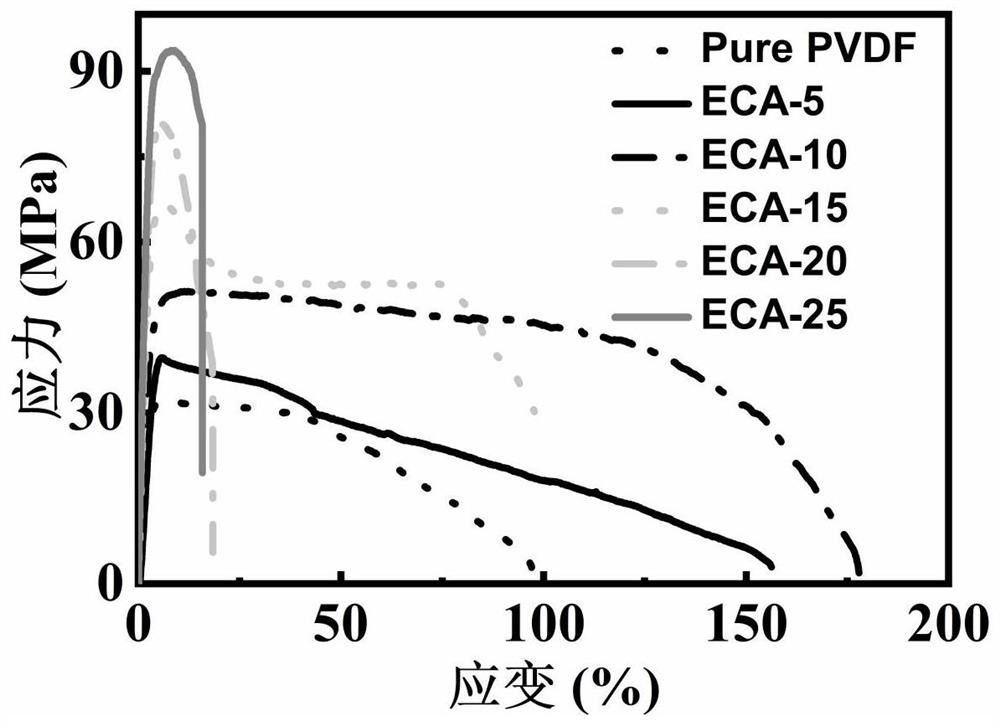

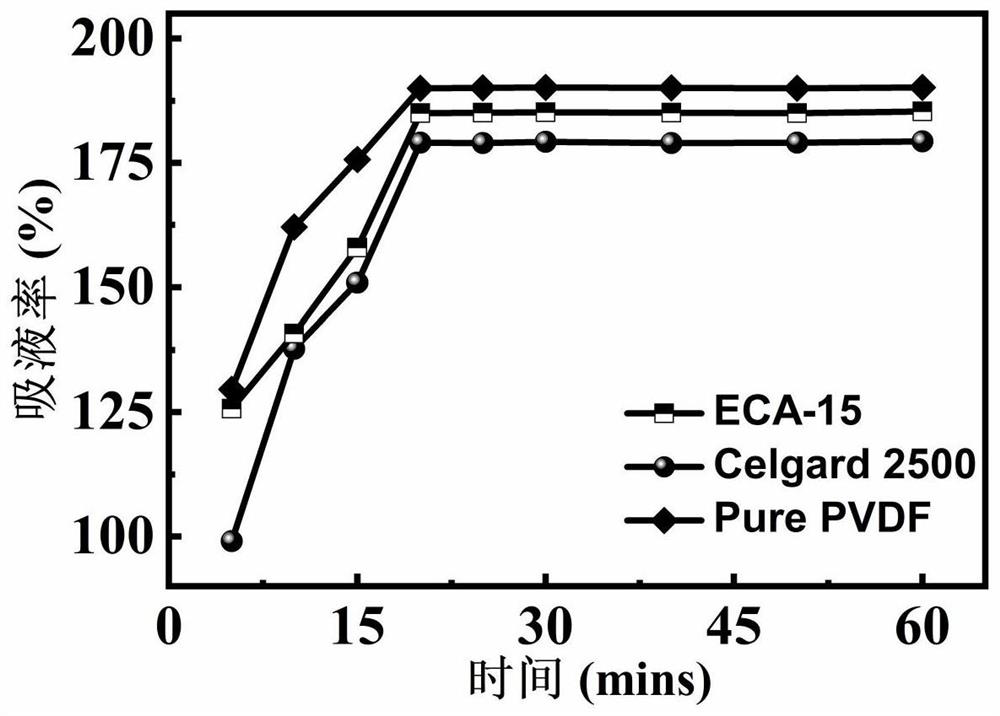

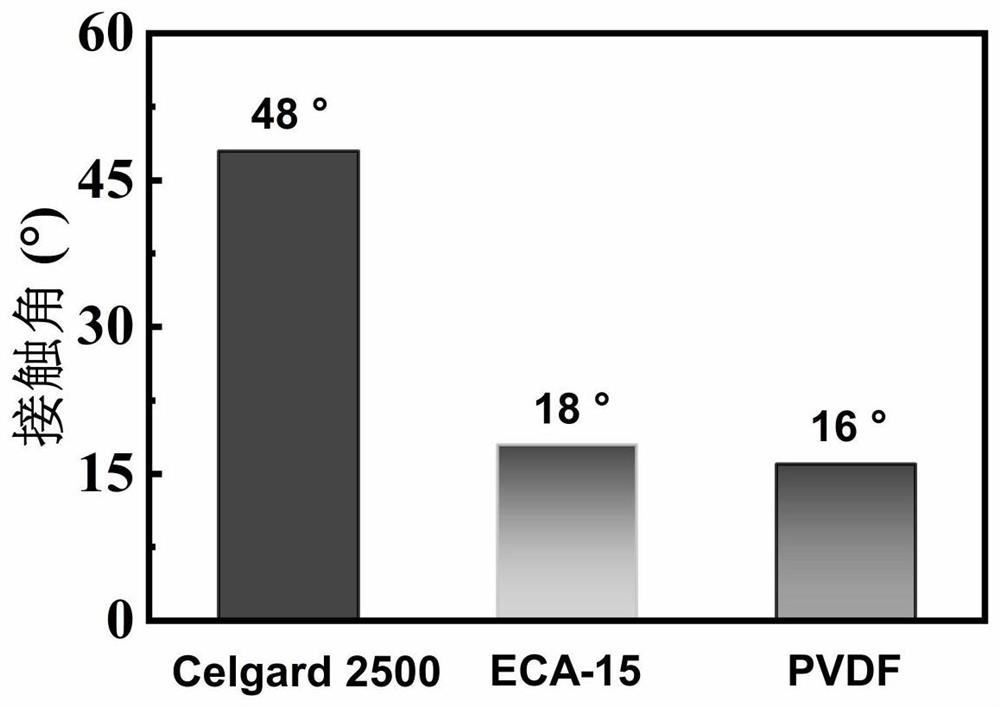

[0023] Specific Embodiment 1: This embodiment describes a lithium-ion battery diaphragm material, which contains the following components in terms of mass percentage: organic solvent 73%-82%, diaphragm substrate 12%-17%, diaphragm Additives 6%-10%.

specific Embodiment approach 2

[0024] Embodiment 2: The lithium-ion battery separator material described in Embodiment 1, the organic solvent includes one or more of acetone, N-methylpyrrolidone or absolute ethanol.

specific Embodiment approach 3

[0025] Specific embodiment three: a lithium-ion battery diaphragm material according to specific embodiment one, the diaphragm substrate is one of polyvinylidene fluoride, polyvinylidene fluoride-hexafluoropropylene or polymethyl methacrylate or Several kinds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com