Powdered oil and preparation method thereof

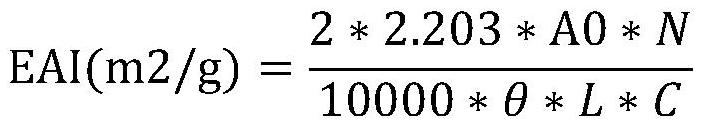

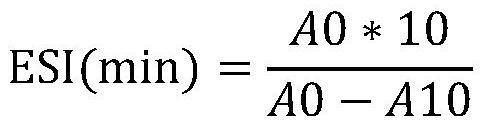

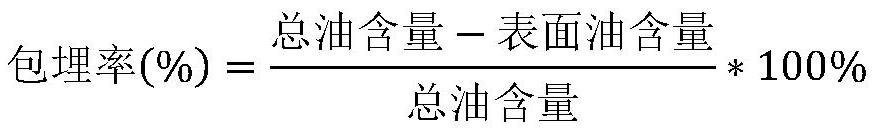

A technology for powder oil and vegetable oil, applied in the field of oil, can solve the problems of low oil content on the surface of soybean powder oil and complex process, and achieve the effects of high embedding rate, good stability and low surface oil content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] Preparation method of powder oil

[0044] A preparation method of powdered oil, said preparation method comprising steps:

[0045] (1) Provide soy milk base material;

[0046] (2) heat-treating the soymilk base material and high-pressure homogenizing treatment to obtain the treated soymilk;

[0047] (3) adding vegetable oil to the soybean milk obtained in step (2), and emulsifying to obtain an oil-in-water emulsion;

[0048] (4) The emulsion obtained in step (3) is spray-dried.

[0049] In some specific embodiments, the solid content of the soybean milk base material is 6% or more, preferably 10% or more.

[0050] In some specific embodiments, the content of fat in the soybean milk base material is 25%-35% of the total solid content.

[0051] In some specific embodiments, the vegetable oil is selected from: rice oil, sunflower oil, high oleic sunflower oil, canola oil, rapeseed oil, palm oil, palm kernel oil, peanut oil, rapeseed oil, soybean oil , cottonseed oil, ...

Embodiment 1

[0108] Take 1000 parts of soymilk base material (solid content is 10%, and oil content is 30% of the total solid content) into a high-temperature and high-pressure reactor, react at 120°C for 1 hour, and then homogenize under high pressure in a homogenizer for 3 minutes. The pressure is 50MPa to obtain the reaction solution; take 425 parts of the reaction solution, add 7.5 parts of corn oil, stir at high speed for 1min, and the rotation speed is 15000rpm, then homogenize under high pressure for 3min, the homogenization pressure is 40MPa, spray the obtained emulsion to obtain powder oil .

Embodiment 2

[0110] Take 1000 parts of soybean milk base material (solid content is 6%, and oil content is 25% of the total solid content) and put it into a high-temperature and high-pressure reaction kettle, react at 110°C for 0.5h, then homogenize under high pressure in a homogenizer for 3min, homogenize The mass pressure is 50MPa to obtain the reaction solution; take 425 parts of the reaction solution, add 7.5 parts of rice oil, stir at a high speed for 1min, and the rotating speed is 15000rpm, then high-pressure homogenization for 3min, the homogenization pressure is 40MPa, and the obtained emulsion is spray-dried to obtain a powder grease.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com