Preparation method of coix seed and Chinese wolfberry composite lactic acid fermented beverage

A technology of lactic acid fermentation and barley, which is applied to the functions of bacteria, lactobacilli, and food ingredients used in food preparation, can solve problems such as poor taste and flavor, loss of active nutrients in fruits and vegetables, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

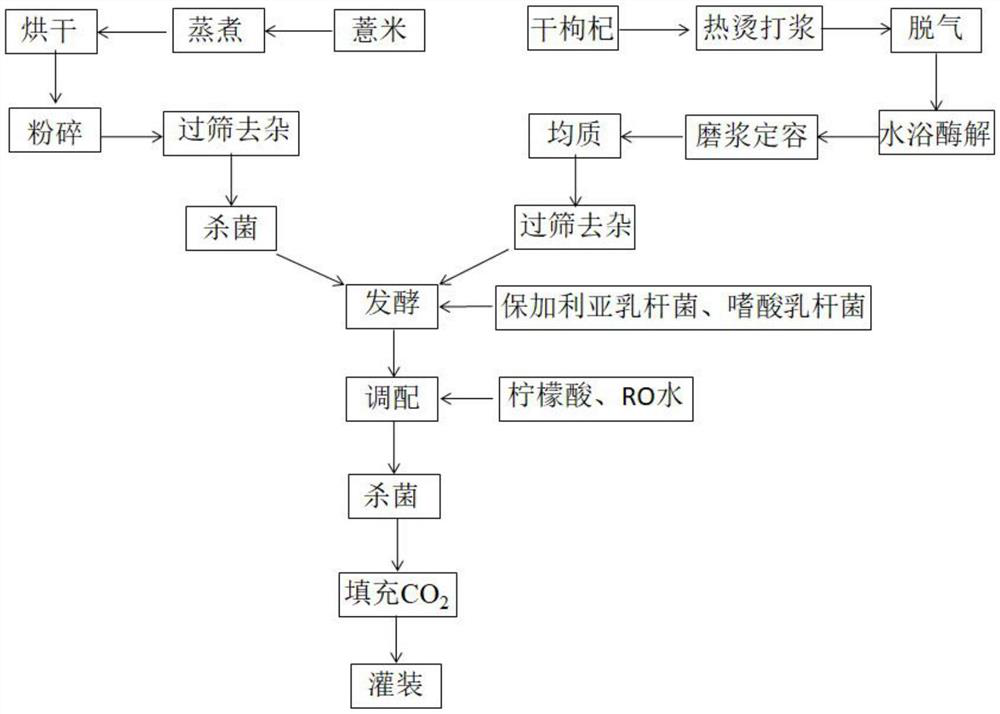

Image

Examples

Embodiment 1

[0014] (1) Select 500g of non-mildew barley, wash and cook, add water according to the solid-to-liquid ratio (mL / g) 35:1, take it out of the pot after 20 minutes, then put it in an oven, bake it at 90°C for 2.5 hours, and take it out. Crush through a 200-mesh sieve, remove impurities, and obtain barley powder; (2) Select 350g of dried wolfberry and put it in water at 70-80°C for 4 minutes to soften the tissue, promote beating, and increase the juice yield. When blanching, add the calcium chloride that mass fraction is 0.4% and the zinc chloride that mass fraction is 0.2% to the water to protect color, obtain about 270g of pulp, for speeding up the juice extraction, add 2 times the quality of distilled water after mixing and beating, Then manually degassed, after being processed by a high-pressure homogenizer, placed in a constant temperature water bath, and kept at 55°C for 120min. Take out the treated fruit pulp, cool it to normal temperature, add 0.08% xylanase for enzymolys...

Embodiment 2

[0016] (1) Select 500g of non-mildew barley, wash it, cook it, add water according to the solid-to-liquid ratio (mL / g) 30:1, take it out of the pot after 20 minutes, then put it in an oven, bake it at 90°C for 2.5 hours, and take it out. Crush through a 200-mesh sieve, remove impurities, and obtain barley powder; (2) Select 350g of dried wolfberry and put it in water at 70-80°C for 4 minutes to soften the tissue, promote beating, and increase the juice yield. When blanching, add the calcium chloride that mass fraction is 0.4% and the zinc chloride that mass fraction is 0.2% to the water to protect color, obtain about 270g of pulp, for speeding up the juice extraction, add 2 times the quality of distilled water after mixing and beating, Then manually degassed, after being processed by a high-pressure homogenizer, placed in a constant temperature water bath, and kept at 55°C for 120min. Take out the treated fruit pulp, cool it to normal temperature, add 0.06% xylanase for enzyma...

Embodiment 3

[0018] (1) Select 500g of non-mildew barley, wash and cook, add water according to the solid-to-liquid ratio (mL / g) 35:1, take it out of the pot after 20 minutes, then put it in an oven, bake it at 90°C for 2.5 hours, and take it out. Crush through a 200-mesh sieve, remove impurities, and obtain barley powder; (2) Select 350g of dried wolfberry and put it in water at 70-80°C for 4 minutes to soften the tissue, promote beating, and increase the juice yield. When blanching, add the calcium chloride that mass fraction is 0.4% and the zinc chloride that mass fraction is 0.2% to the water to protect color, obtain about 270g of pulp, for speeding up the juice extraction, add 2 times the quality of distilled water after mixing and beating, Then manually degassed, after being processed by a high-pressure homogenizer, placed in a constant temperature water bath, and kept at 55°C for 120min. Take out the treated fruit pulp, cool it to normal temperature, add 0.06% xylanase for enzymatic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com