Magnetic iron-based composite oxide adsorbent for removing polymorphic arsenic and preparation method thereof

A composite oxide and polymorphic technology, applied in chemical instruments and methods, alkali metal oxides/hydroxides, alkali metal compounds, etc., can solve the problems of easy hardening, difficult separation of arsenic-removing composite oxide adsorbents, and removal efficiency High adsorption capacity, excellent water purification efficiency, easy magnetic separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

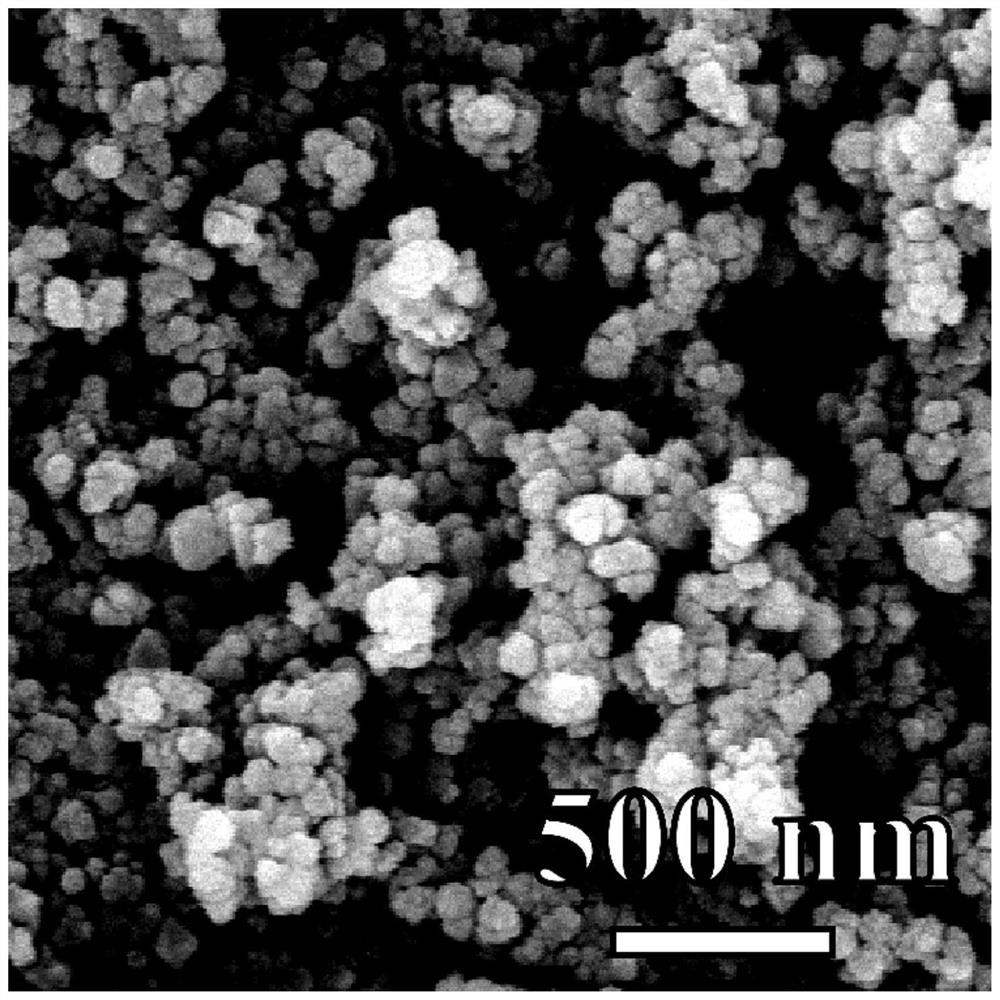

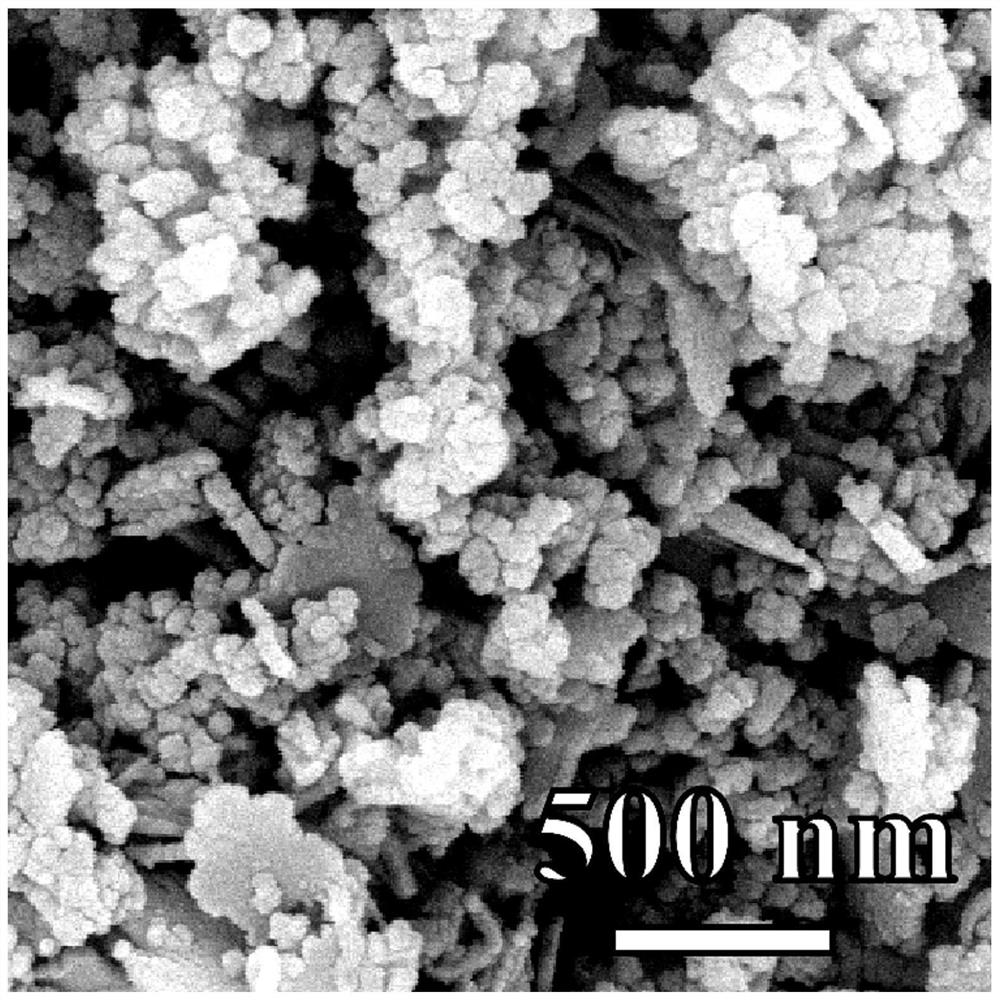

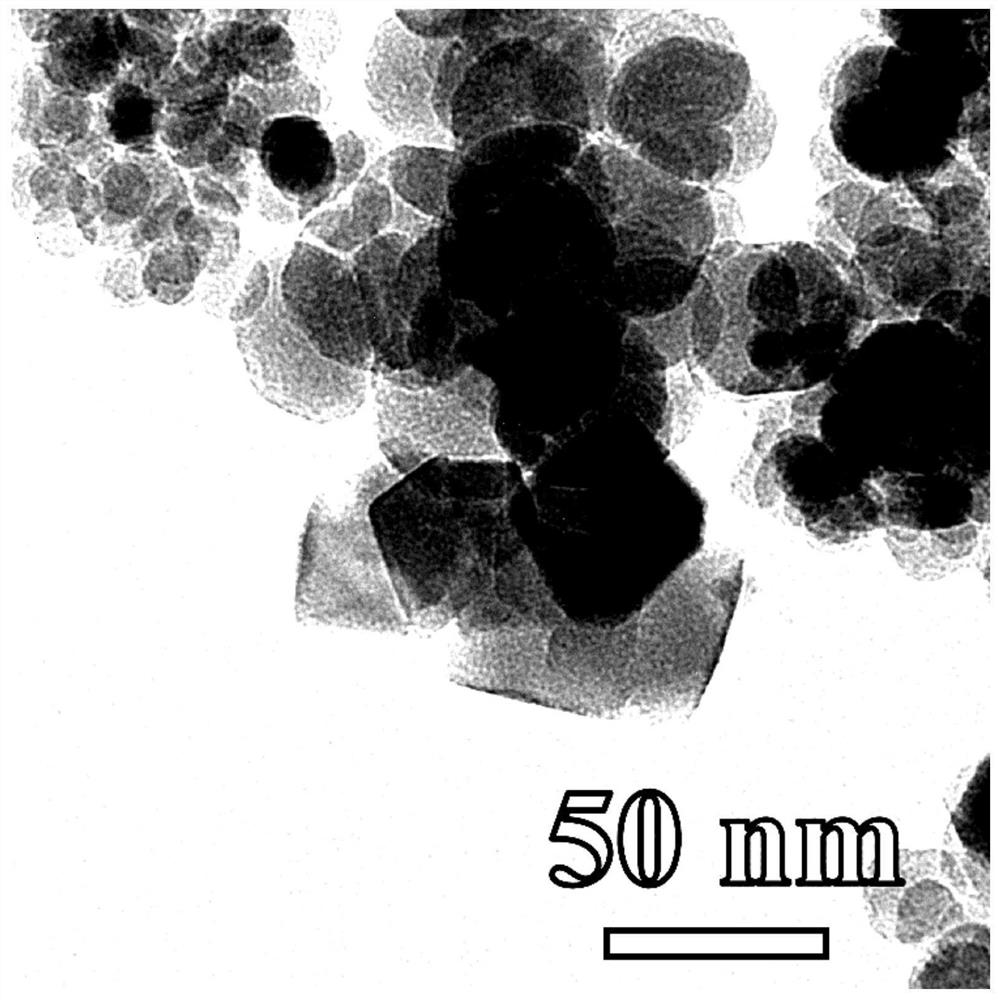

[0026] Specific embodiment 1: This embodiment is a magnetic iron-based composite oxide adsorbent for removing polymorphic arsenic, which is a coated core-shell structure, with magnetic ferroferric oxide as the core and copper-lanthanum composite oxide as the shell .

specific Embodiment approach 2

[0027] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the molar ratio of magnetic ferric iron tetroxide, copper element and lanthanum element in the magnetic iron-based composite oxide adsorbent for removing polymorphic arsenic is ( 1~4):1:(0.5~2). Others are the same as the first embodiment.

specific Embodiment approach 3

[0028] Specific embodiment three: This embodiment is the preparation method of the magnetic iron-based composite oxide adsorbent for removing polymorphic arsenic in the specific embodiment one, specifically as follows:

[0029] 1. Preparation of core magnetic ferric oxide: Mix soluble ferric salt and soluble ferrous salt in water to obtain a mixed solution of ferric salt, heat the mixed solution of ferric salt to 50°C to 80°C and keep the temperature between 50°C and 80°C Slowly stir for 0.5h~1h under the condition of 50℃~80℃ and rapid stirring, then dropwise add lye to pH 10~12 under the condition of 50℃~80℃ and rapid stirring, continue to stir for 2h under the condition of 50℃~80℃ and rapid stirring ~2.5h, stop stirring, age at 50°C~80°C for 12h~24h, wash with water, filter, dry at 80°C~85°C, and grind to obtain core magnetic iron tetroxide;

[0030] The molar ratio of ferric iron and ferrous iron in the iron salt mixed solution is 1:(2~0.5);

[0031] The molar concentratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com