Preparation method for SnBi-series lead-free solder containing graphene and MAX phase

A lead-free solder and graphene technology, applied in the field of low-temperature soldering materials and electronic packaging, can solve problems such as premature failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

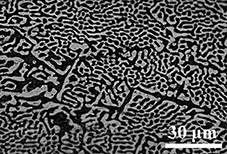

[0027] A kind of SnBi low-temperature lead-free solder containing graphene and MAX phase, in its composition, Sn58Bi, GNSs and Ti 3 AlC 2 The mass ratio is 99.87%: 0.03%: 0.1%. Wherein the thickness of graphene nanosheet is 1-5nm, Ti 3 AlC 2 The thickness of the tin-bismuth alloy is less than 1 μm, and the tin-bismuth alloy is a metal powder. In the powder, the mass percentage of tin is 42%, the mass percentage of bismuth is 58%, and the particle diameter of the powder is 30-60 μm.

Embodiment 2

[0029] A kind of SnBi low-temperature lead-free solder containing graphene and MAX phase, in its composition, Sn58Bi, GNSs and Ti 3 AlC 2 The mass ratio is 99.77%: 0.03%: 0.2%. Wherein the thickness of graphene nanosheet is 1-5nm, Ti 3 AlC 2 The thickness of the tin-bismuth alloy is less than 1 μm, and the tin-bismuth alloy is a metal powder. In the powder, the mass percentage of tin is 42%, the mass percentage of bismuth is 58%, and the particle diameter of the powder is 30-60 μm.

Embodiment 3

[0031] A kind of SnBi low-temperature lead-free solder containing graphene and MAX phase, in its composition, Sn58Bi, GNSs and Ti 3 AlC 2 The mass ratio is 99.47%: 0.03%: 0.5%. Wherein the thickness of graphene nanosheet is 1-5nm, Ti 3 AlC 2 The thickness of the tin-bismuth alloy is less than 1 μm, and the tin-bismuth alloy is a metal powder. In the powder, the mass percentage of tin is 42%, the mass percentage of bismuth is 58%, and the particle diameter of the powder is 30-60 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com