Earphone wire material and preparation process thereof

A preparation process and a technology for an earphone cable, which are applied in the field of earphone cable materials and their preparation technology, can solve the problems of adhesion and stains of the outer jacket protection material, poor antifouling performance of the outer jacket protection material, etc., achieve good chemical stability, and improve oil resistance. and water stain resistance, the effect of improving stain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

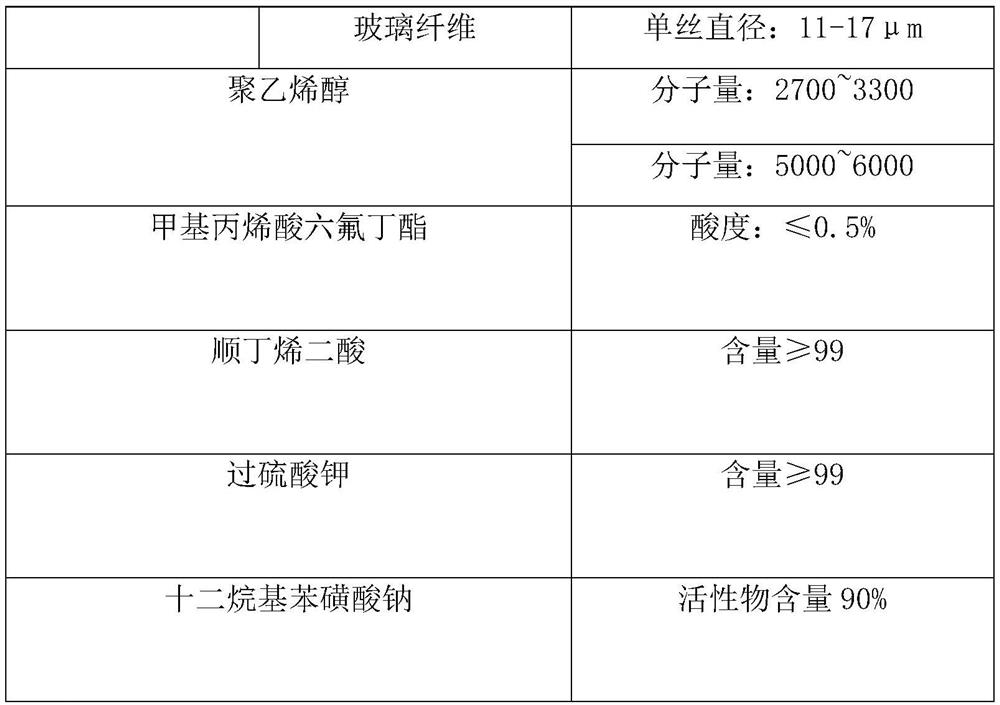

Method used

Image

Examples

Embodiment 1-4

[0037] Preparation of modified polyvinyl alcohol: put a beaker containing 1kg of water into a constant temperature oil bath, adjust the temperature of the constant temperature oil bath to 95°C, weigh the polyvinyl alcohol dissolved in water according to the ratio in Table 2, Add emulsifier and initiator and stir to dissolve, add hexafluorobutyl methacrylate, stir and react at constant temperature for 45 minutes, take out the beaker and put it in an oven at 80°C for 2 hours to evaporate to obtain modified polyvinyl alcohol;

[0038] Preparation of finished products: put modified polyvinyl alcohol, TPU resin, POE and fillers into an internal mixer, banbury and blend at 155°C, cool and crush to particles with a particle size of 3-7mm, and crush the particles Put it into an extruder for extrusion granulation. The extrusion temperature is 165°C, 160°C, 155°C, 150°C, and 145°C from the discharge port to the feed port in order to obtain the earphone wire material.

Embodiment 5-7

[0040] Preparation of modified polyvinyl alcohol: put a beaker containing 1kg of water into a constant temperature oil bath, adjust the temperature of the constant temperature oil bath to 95°C, weigh the polyvinyl alcohol dissolved in water according to the ratio in Table 2, Add maleic acid to react for 15 minutes, add emulsifier and initiator and stir to dissolve, add hexafluorobutyl methacrylate, stir and react at constant temperature for 45 minutes, then take out the beaker and put it in an oven at 80°C for 2 hours to evaporate to obtain the improved product. non-toxic polyvinyl alcohol;

[0041] Preparation of finished products: put modified polyvinyl alcohol, TPU resin, POE and fillers into an internal mixer, banbury and blend at 155°C, cool and crush to particles with a particle size of 3-7mm, and crush the particles Put it into an extruder for extrusion granulation. The extrusion temperature is 165°C, 160°C, 155°C, 150°C, and 145°C from the discharge port to the feed po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com