Waterproof paper straw adhesive and preparation method thereof

A technology for adhesives and straws, which is applied in the direction of adhesives, monocarboxylate copolymer adhesives, adhesive types, etc., and can solve problems such as scattering, tube warping, and unfavorable production efficiency of paper straws

- Summary

- Abstract

- Description

- Claims

- Application Information

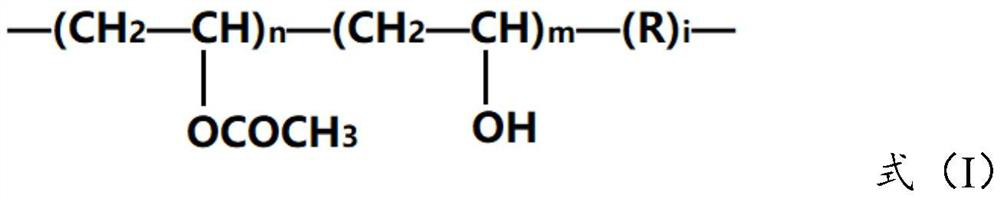

AI Technical Summary

Problems solved by technology

Method used

Image

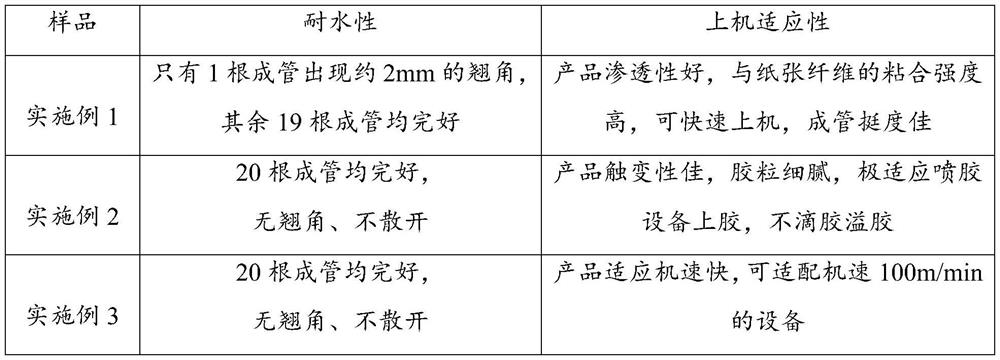

Examples

Embodiment 1

[0034] A water-resistant paper straw adhesive, comprising the following components by mass percentage:

[0035] Vinyl acetate emulsion 11%;

[0036] Tertiary acrylic emulsion 41%;

[0037] Polyvinyl succinate 4.2%;

[0038] Chitosan 1.6%;

[0039] Silicone defoamer 1.1%;

[0040] Sorbic acid 1.2%;

[0041] Deionized water 38.9%.

[0042] The preparation method of this water-resistant paper straw adhesive is as follows:

[0043] 1) Heat 29% deionized water to 81°C, add 1.6% chitosan while stirring, keep warm for 2 hours, cool down to 11°C, add 1.1% silicone defoamer and 1.2% sorbic acid, stir evenly, and prepare Get A component;

[0044] 2) Dissolve 4.2% polyvinyl succinate in 11% deionized water, add dropwise to 41% tert-acrylic emulsion at 78°C, raise the temperature to 87°C and keep it warm for 31 minutes; then cool down to 11°C, add 11 % polyvinyl acetate emulsion, stirred evenly to obtain component B;

[0045] 3) Mix component A and component B evenly to obtain a ...

Embodiment 2

[0047] A water-resistant paper straw adhesive, comprising the following components by mass percentage:

[0048] Vinegar Acrylic Emulsion 18%;

[0049] Styrene-acrylic emulsion 37%;

[0050] Maleic acid polyvinyl alcohol crosslinking compound 2.1%;

[0052] Polyether silicon defoamer 1.2%;

[0053] Sodium dehydroacetate 1.2%;

[0054] Deionized water 41.9%.

[0055] The preparation method of this water-resistant paper straw adhesive is as follows:

[0056] 1) Heat 31.9% deionized water to 71°C, add 1.2% cellulose ether while stirring, keep warm for 2 hours, cool down to 41°C, add 1.2% polyether defoamer and 1.2% sodium dehydroacetate, stir well , to obtain component A;

[0057] 2) Dissolve 2.1% maleic acid polyvinyl alcohol cross-linking compound in 11% deionized water, add it dropwise to 37% styrene-acrylic emulsion at 78°C, raise the temperature to 91°C and keep it warm for 31min; then cool down to 11°C, Add 18% vinegar-acrylic emulsion ...

Embodiment 3

[0060] A water-resistant paper straw adhesive, comprising the following components by mass percentage:

[0061] Vinegar-acrylic emulsion 22%;

[0062] Styrene-acrylic emulsion 11%;

[0063] Pure acrylic emulsion 31%;

[0064] Maleic acid polyvinyl alcohol crosslinking compound 3.9%;

[0065] Edible starch 2.2%;

[0066] Grease defoamer 1.2%;

[0067] Sodium dehydroacetate 1.2%;

[0068] Deionized water 26.1%.

[0069] The preparation method of this water-resistant paper straw adhesive is as follows:

[0070] 1) Heat 11.1% deionized water to 71°C, add 2.2% edible starch while stirring, keep warm for 2 hours, cool down to 41°C, add 1.2% grease defoamer and 1.2% sodium dehydroacetate, stir well, Prepare A component;

[0071] 2) Dissolve 3.9% maleic acid polyvinyl alcohol cross-linking compound in 11% deionized water, add dropwise to the mixture of 11% styrene-acrylic emulsion and 31% pure acrylic emulsion at 78°C, heat up to 89°C and keep it warm 31min; then lower the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com