Method for determining concentration of liquid

A technology of concentration and liquid, which is applied in the direction of vibration measurement in fluid, measurement of propagation velocity, detection of response signal, etc., and can solve problems such as change of measurement section and degradation of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] figure 1 Components of the SCR catalytic converter system 1 of the motor vehicle, not shown, are shown. The SCR catalytic converter system has a reductant tank 2 . A liquid 3 , which is HWL, is stored in the reducing agent tank 2 . The extraction module 4 is arranged at the bottom of the reducing agent tank 2 . The extraction module carries a delivery device 5 , by means of which liquid 3 can be drawn from the reducing agent tank 2 and transported by means of a line 6 to a metering valve of the SCR catalytic converter system 1 . To determine the concentration of the liquid 3 , a mass sensor 7 is arranged on the extraction module 4 , which is controlled by an electronic control unit 8 .

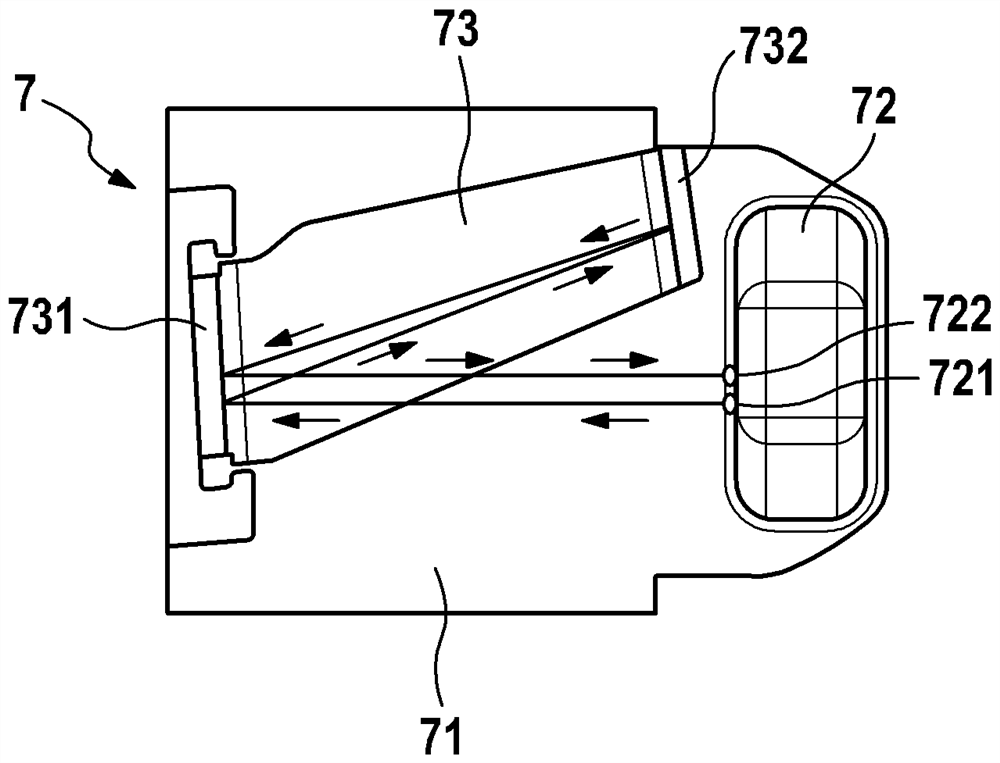

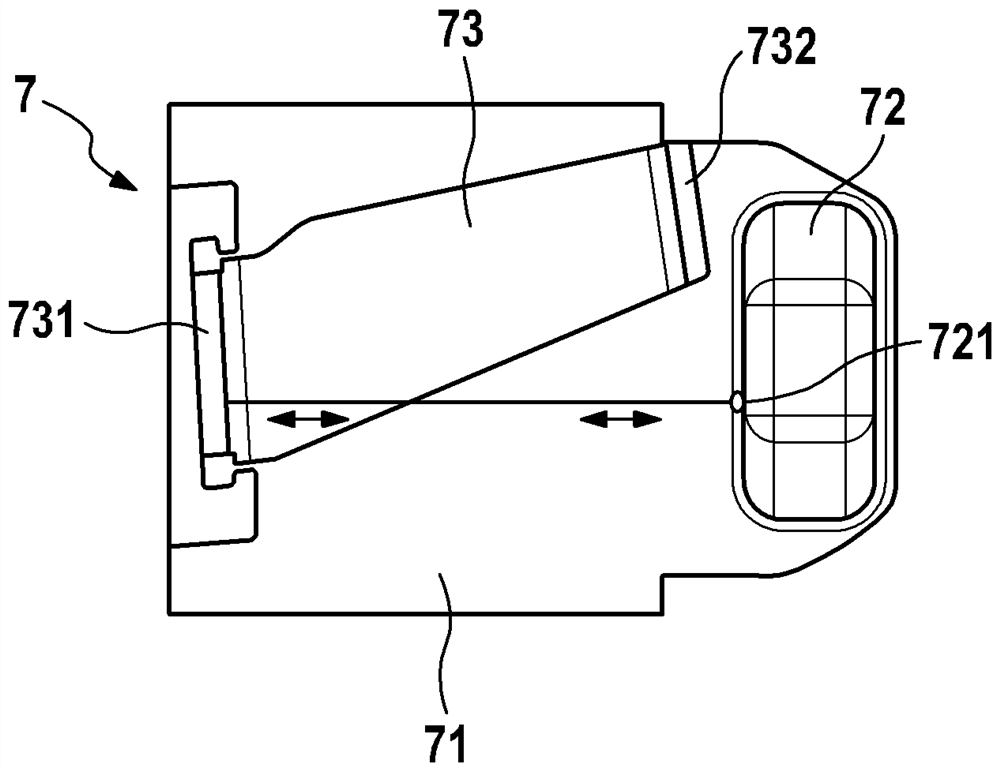

[0023] as in figure 2 As shown in , the mass sensor 7 has a base 71 , which in the exemplary embodiment consists of HDPE (High Density Polyethylene, high-density polyethylene). An ultrasonic transducer 72 is arranged on the base. Furthermore, in the present exemplary embodiment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com