Magnetic fullerene nano-material and application thereof in magnetic dispersion solid-phase extraction of methyl methoxyacrylate pesticides

A technology of methyl methoxyacrylate and magnetic fullerene, which can be used in material separation, analysis of materials, other chemical processes, etc., can solve the problems of complicated operation steps, difficult recycling of adsorbents, long time consumption, etc., and achieves good selectivity. , save processing time and cost, method fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

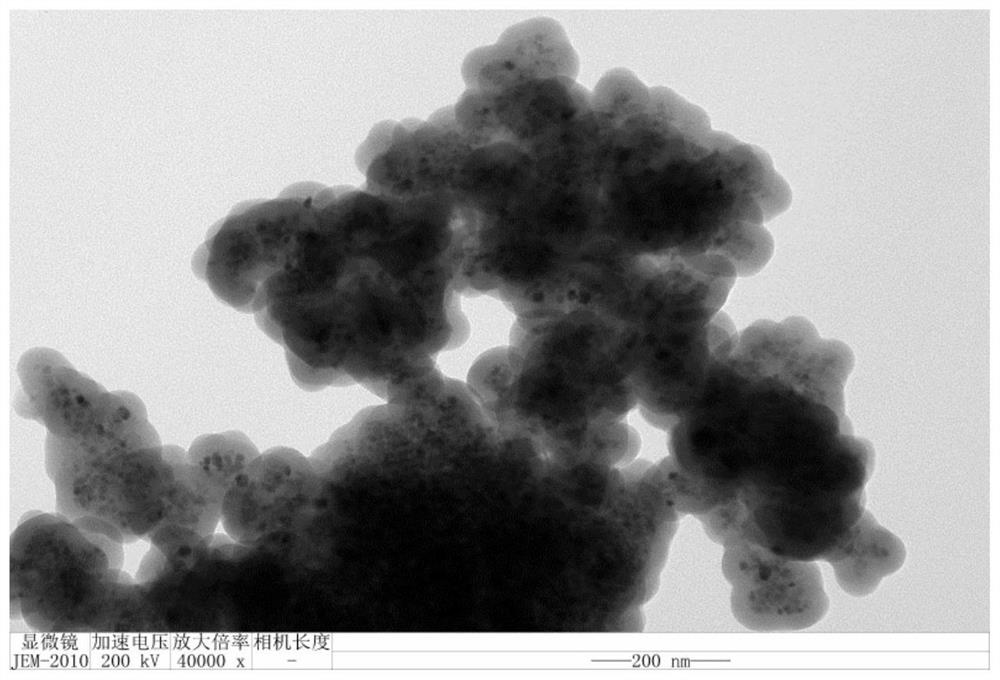

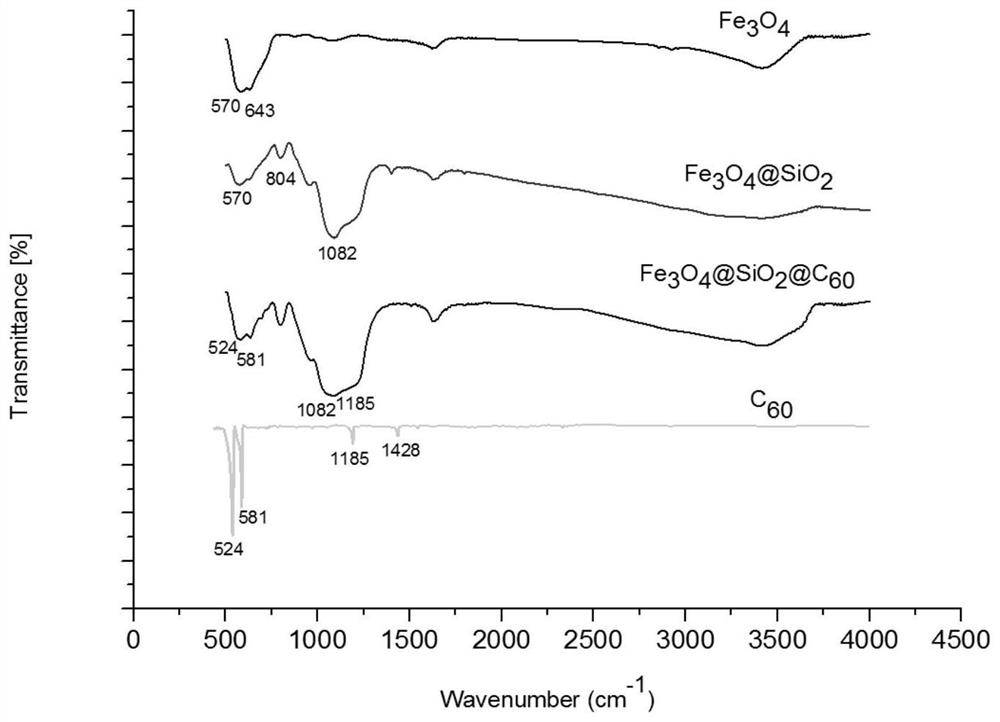

[0033] This embodiment prepares Fe according to the following steps 3 o 4 @SiO 2 @C 60 Nanoparticles:

[0034] Step 1, 1g Fe 3 o 4 Nanoparticles were dispersed in 100mL isopropanol and 8mL water, ultrasonically dispersed for 15min, blown with nitrogen and stirred at room temperature; then added 10mL ammonia water with a mass concentration of 26%, stirred for 5min, added 8mL tetraethyl orthosilicate, and heated to 45°C Stir for 12 h; magnetically separate the product, wash with deionized water and ethanol in turn, and dry under vacuum at 60 °C for 12 h to obtain Fe 3 o 4 @SiO 2 Nanoparticles;

[0035] Step 2, the Fe synthesized in step 1 3 o 4 @SiO 2 Nanoparticles were dissolved in 100mL toluene, stirred at room temperature for 30min with nitrogen gas; then 1mL triethylamine and 2mL 3-chloropropyltrimethoxysilane were added, and the temperature was raised to 110°C to continue the reaction for 24h; cooled to room temperature, the product was magnetically separated, an...

Embodiment 2

[0040] This embodiment prepares Fe according to the following steps 3 o 4 @SiO 2 @C 60 Nanoparticles:

[0041] Step 1, 2g Fe 3 o 4 Nanoparticles were dispersed in 200mL of isopropanol and 16mL of water, ultrasonically dispersed for 15min, blown with nitrogen and stirred at room temperature; then added 20mL of ammonia water with a mass concentration of 26%, stirred for 5min, added 16mL of tetraethyl orthosilicate, and heated to 45°C Stir for 12 h; magnetically separate the product, wash with deionized water and ethanol in turn, and dry under vacuum at 60 °C for 12 h to obtain Fe 3 o 4 @SiO 2 Nanoparticles;

[0042] Step 2, the Fe synthesized in step 1 3 o 4 @SiO 2 Nanoparticles were dissolved in 200mL of toluene, stirred at room temperature for 30min with nitrogen gas; then 2mL of triethylamine and 4mL of 3-chloropropyltrimethoxysilane were added, and the temperature was raised to 110°C to continue the reaction for 24h; cooled to room temperature, the product was mag...

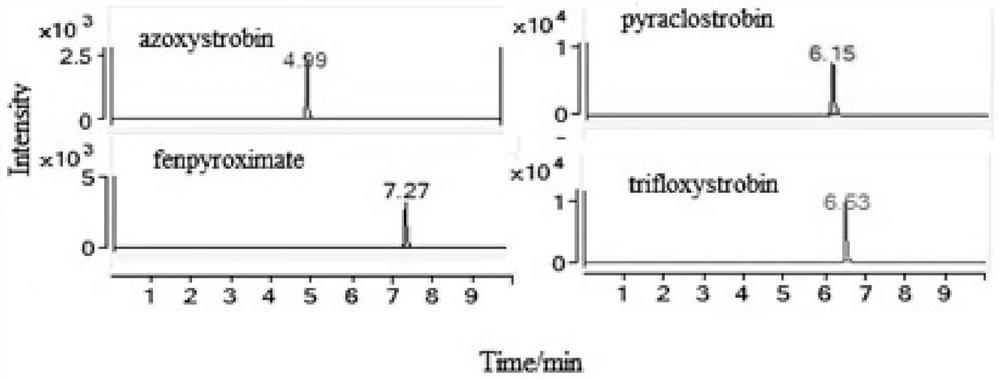

Embodiment 3、 application example

[0047] The above-mentioned embodiment gained Fe 3 o 4 @SiO 2 @Cl nanoparticles can be used as magnetic dispersive solid phase extraction adsorbent for magnetic dispersive solid phase extraction of methyl methoxyacrylate pesticides in water samples or fruit and vegetable samples, and combined with UHPLC-MS / MS analysis to determine the Measuring the concentration of methyl methoxyacrylate pesticides in water samples or fruit and vegetable samples. Specific steps are as follows:

[0048] Step 1. Extraction

[0049] The extraction method of the environmental water sample is as follows: draw 1mL of the water sample to be tested into a 15mL conical centrifuge tube, add 9mL of ultrapure water and mix well, then add 30mg of the magnetic fullerene nanomaterial obtained in the above examples, shake and extract for 20min; The magnetic fullerene nanomaterials gather to the bottom, pour all the solution;

[0050] The extraction method of fruit and vegetable samples is as follows: Weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com