Additive for removing winding plating of polycrystalline silicon or amorphous silicon of silicon solar cell, winding plating removing method and method for improving yield of N-type cell

A technology of silicon solar cells and additives, which is applied in the field of solar cells, can solve the problems of insufficient cleaning of N-type high-efficiency batteries, poor cleaning effect of chain equipment, etc., and achieve process and equipment improvement, high safety, and process good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

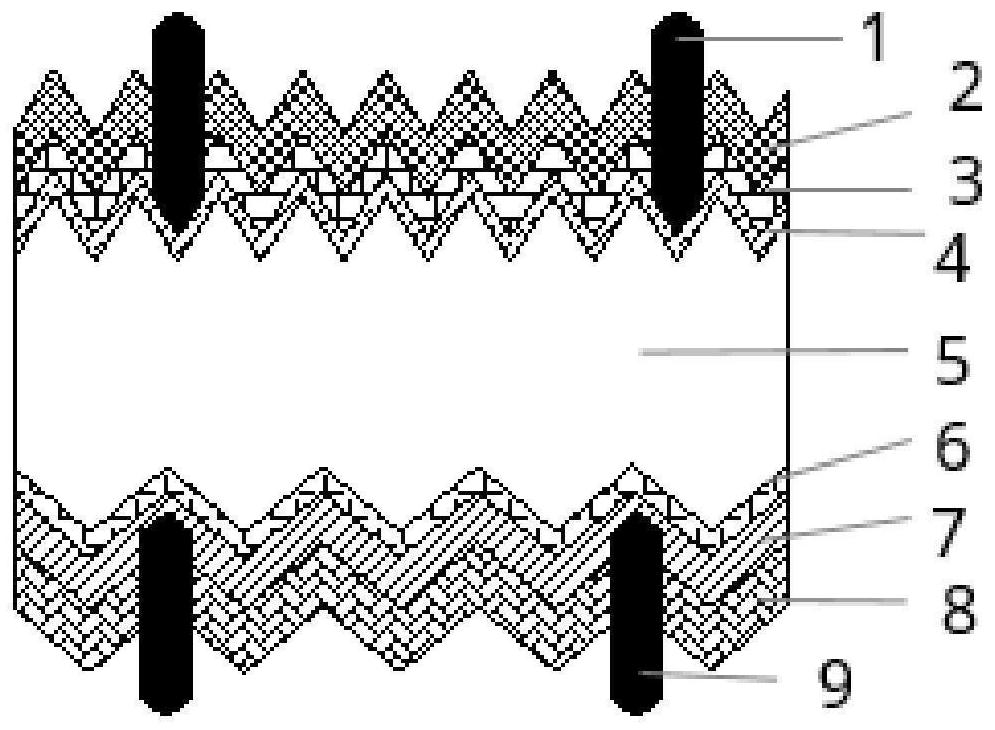

Image

Examples

Embodiment 1

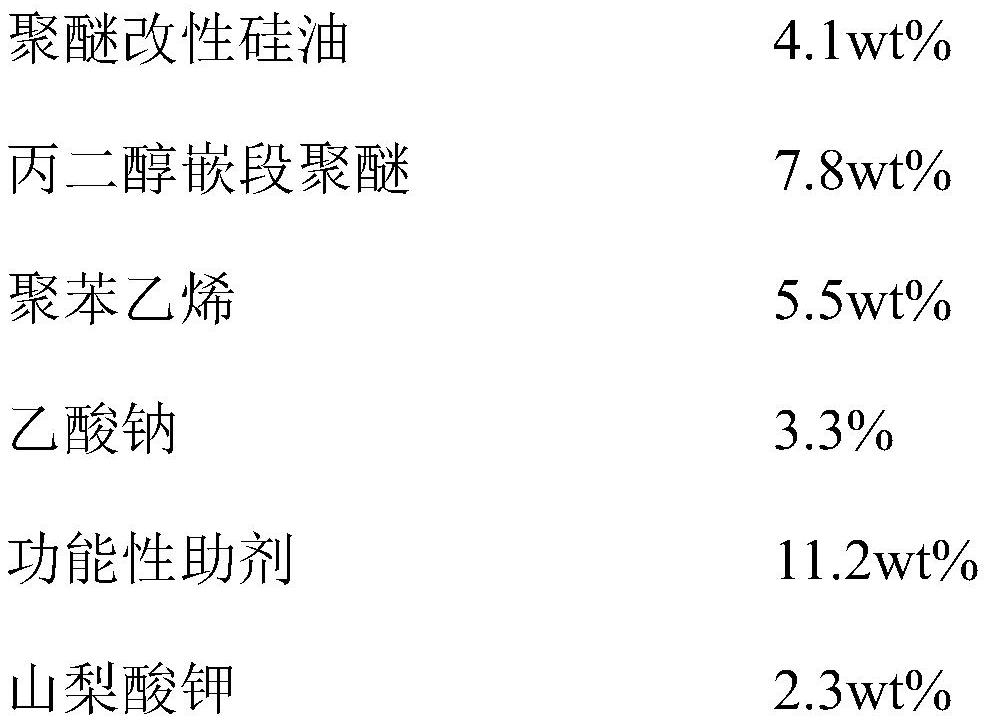

[0059] This embodiment provides an additive and a method for improving the yield of an N-type battery by using the additive. The composition of described additive is:

[0060]

[0061] the rest is water,

[0062] Wherein, the functional additive is a mixture of acetone and aluminum isopropoxide in a mass ratio of 1:1.

[0063] The methods include:

[0064] 1 Pre-cleaning the silicon wafer coated with polysilicon on the front side in an aqueous solution containing additives, the additive content is 2wt%, and the pre-cleaning temperature is 25°C;

[0065] 2. Remove the polysilicon on the front side by adding KOH and additives to the above pre-cleaned silicon wafers. The reaction temperature is 70° C., the KOH content is 4.5 wt%, and the additive content is 2 wt%.

[0066] Observe the appearance of the obtained battery sheet. If there is color difference in appearance, it is a substandard product, and if there is no color difference in appearance, it is a qualified product....

Embodiment 2

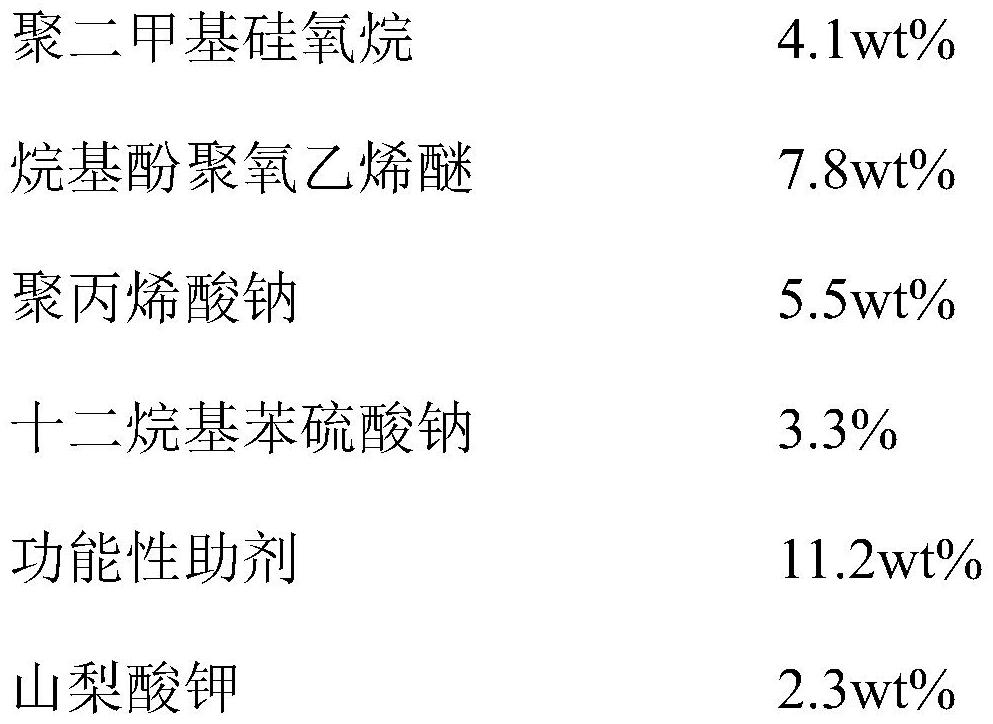

[0069] This embodiment provides an additive and a method for improving the yield of an N-type battery by using the additive. The composition of described additive is:

[0070]

[0071] the rest is water,

[0072] Wherein, the functional additive is a mixture of aluminum isopropoxide, tert-butanol peroxide and triphenyl phosphite in a mass ratio of 1:2:1.

[0073] The methods include:

[0074] 1. The silicon wafer coated with amorphous silicon on the front side is pre-washed in an aqueous solution containing additives, the additive content is 2wt%, and the pre-cleaning temperature is 25°C;

[0075] 2. The above pre-cleaned silicon wafer is passed through an aqueous solution added with KOH and additives to remove the amorphous silicon on the front side. The reaction temperature is 60°C, the KOH content is 4wt%, and the additive content is 3wt%.

[0076] In this embodiment, the yield rate of the battery after dewinding plating is 93%.

Embodiment 3

[0078] This embodiment provides an additive and a method for improving the yield of an N-type battery by using the additive. The composition of described additive is:

[0079]

[0080] the rest is water,

[0081] Wherein, the functional additive is a mixture of aluminum isopropoxide, tert-butanol peroxide and three-membered cyclic ether in a mass ratio of 1:3:4.

[0082] The methods include:

[0083] 1. Pre-clean the silicon wafer coated with polysilicon on the front side in an aqueous solution containing additives, the additive content is 1 wt%, and the pre-cleaning temperature is 40°C;

[0084] 2. Remove the polysilicon on the front side from the pre-cleaned silicon wafer in an aqueous solution with NaOH and additives. The reaction temperature is 50° C., the NaOH content is 7.5 wt %, and the additive content is 2.2 wt %.

[0085] In this embodiment, the yield rate of the battery after dewinding plating is 92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com