All-solid-state battery and preparation method thereof

An all-solid-state battery, electrolyte layer technology, applied in the manufacture of electrolyte batteries, lithium batteries, secondary batteries, etc., can solve the problems of chemical stability, capacity and cycle stability, etc., to improve ion conductivity and reduce resistance. , the effect of strong design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

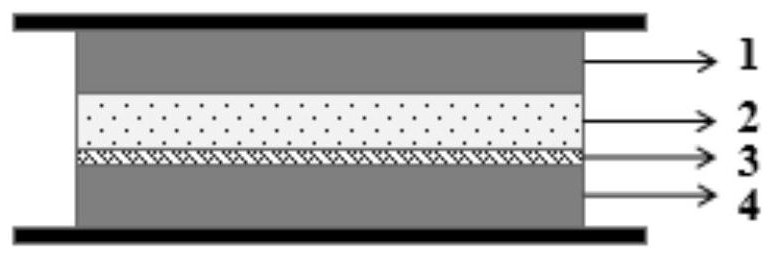

Image

Examples

preparation example Construction

[0038] The raw materials for the preparation of the multifunctional intermediate layer include polymers, ionic liquid monomers, initiators and solvents;

[0039] The ionic liquid monomer contains at least one unsaturated carbon-carbon double bond;

[0040] The cation of the ionic liquid monomer is selected from one or more combinations of piperidinium cations, quaternary ammonium salt cations and pyrrole cations.

[0041] Preferably, the preparation method of the multifunctional intermediate layer comprises the following steps:

[0042] Mix high molecular polymer, ionic liquid monomer, initiator and solvent to prepare multifunctional interlayer slurry;

[0043] Polymerized by heating, then dried.

[0044] Preferably, the heating polymerization temperature is 50-100°C.

[0045] It can be understood that the drying can be vacuum drying or heating vacuum drying, the purpose is to remove the solvent. Preferably, the temperature of heating and vacuum drying is 50-100°C, and the t...

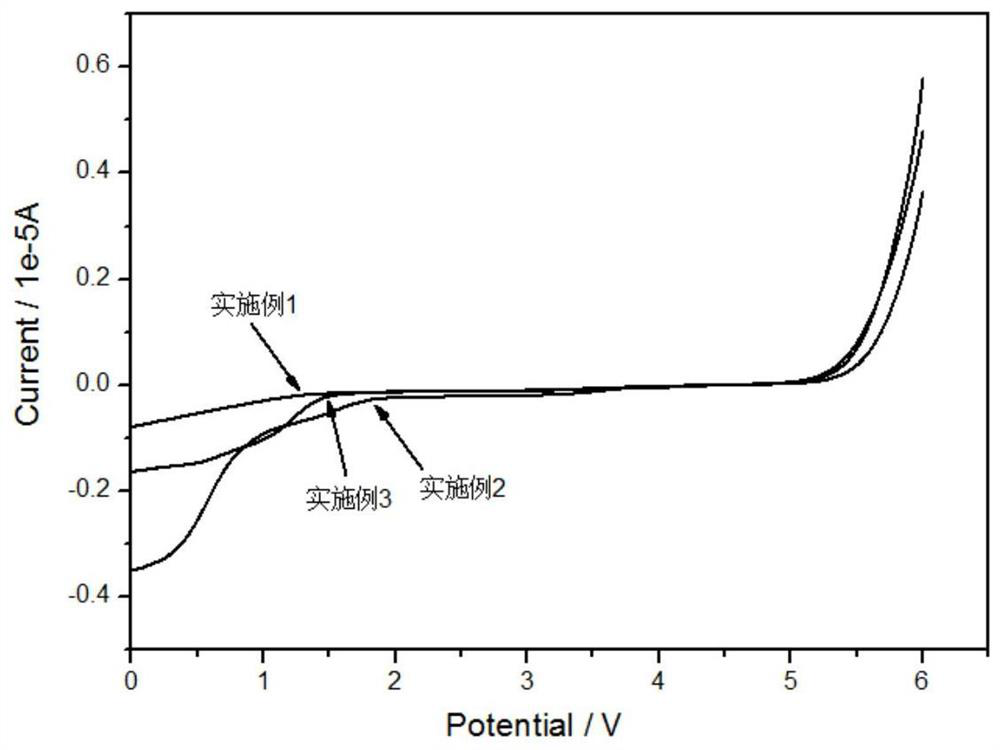

Embodiment 1

[0078] This embodiment provides an all-solid-state battery and its preparation method, the preparation method is as follows:

[0079] (1) First configure the organic-inorganic composite electrolyte layer slurry, the composition of the organic-inorganic composite electrolyte layer slurry is polyacrylonitrile with a molecular weight of 600,000, Li 7 La 3 Zr 2 o 12 , lithium bistrifluoromethanesulfonimide [LiN(SO 2 CF 3 ) 2 ] and N,N-dimethylformamide. Using N,N-dimethylformamide as solvent, polyacrylonitrile, Li 7 La 3 Zr 2 o 12 The organic-inorganic composite electrolyte slurry with a solid content of 15% is configured with lithium bistrifluoromethanesulfonimide at a mass ratio of 80:20:10.

[0080] (2) Place the commercial ternary NCM523 electrode sheet on a flat-plate coating machine, use a scraper to coat a layer of organic-inorganic composite electrolyte layer slurry obtained in step (1) on the side of the electrode sheet with ternary NCM523, and place it at 80°C ...

Embodiment 2

[0085] This example provides an all-solid-state battery and its preparation method. The main difference from Example 1 is that the ionic liquid monomer is different, and the preparation method is as follows:

[0086] (1) First configure the organic-inorganic composite electrolyte layer slurry, the composition of the organic-inorganic composite electrolyte layer slurry is polyacrylonitrile with a molecular weight of 600,000, Li 7 La 3 Zr 2 o 12 , lithium bistrifluoromethanesulfonimide [LiN(SO 2 CF 3 ) 2 ] and N,N-dimethylformamide. Using N,N-dimethylformamide as solvent, polyacrylonitrile, Li 7 La 3 Zr 2 o 12The organic-inorganic composite electrolyte slurry with a solid content of 15% is configured with lithium bistrifluoromethanesulfonimide at a mass ratio of 80:20:10.

[0087] (2) Place the commercial ternary NCM523 electrode sheet on a flat-plate coating machine, use a scraper to coat a layer of organic-inorganic composite electrolyte layer slurry obtained in step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com