Preparation and application of porous basic lanthanum carbonate phosphate adsorbent

A technology of lanthanum carbonate phosphate and adsorbent, applied in the direction of adsorption of water/sewage treatment, alkali metal compounds, other chemical processes, etc., can solve the problems of unsatisfactory adsorption effect, low adsorption rate, poor selectivity, etc., and achieve good recycling properties, high adsorption capacity, and fast adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] 0.2mol of LaCl 3 ·7H 2 O, 1.2 mol of urea and 0.04 mol of sodium citrate were dissolved in 80 mL of deionized water, and the mixed solution was gently magnetically stirred at room temperature for 10 minutes, then sonicated for 20 minutes, and then transferred to a polytetrafluoroethylene liner, The hydrothermal reaction was carried out at 140°C in the reaction kettle. After the reaction was completed, it was cooled to room temperature, the above solution was filtered and washed with deionized water and ethanol, and then the filter cake was dried in an oven at 60°C to finally obtain a white solid product, namely is a porous adsorbent.

[0052] Wherein the hydrothermal reaction time is 4.5 hours.

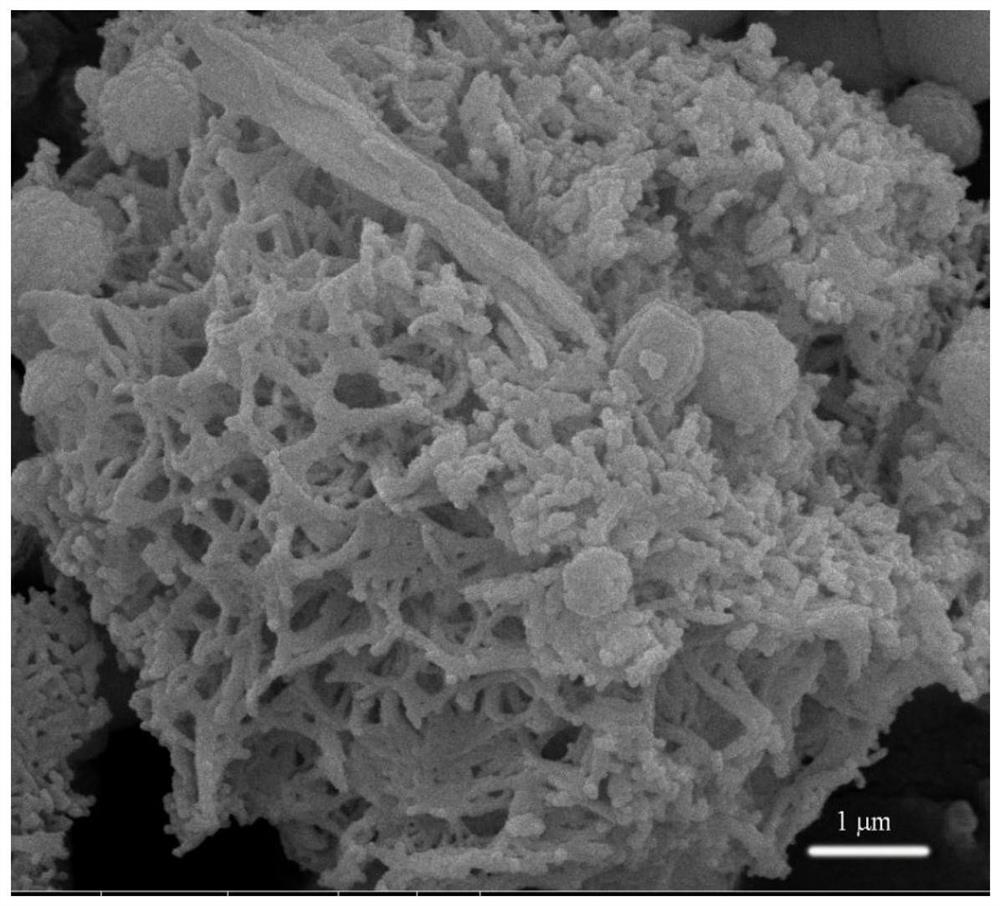

[0053] It was characterized by electronic scanning, and the results are shown in the attached figure 1 As shown, it can be seen that the prepared LaCO 3 OH has a hierarchical porous structure.

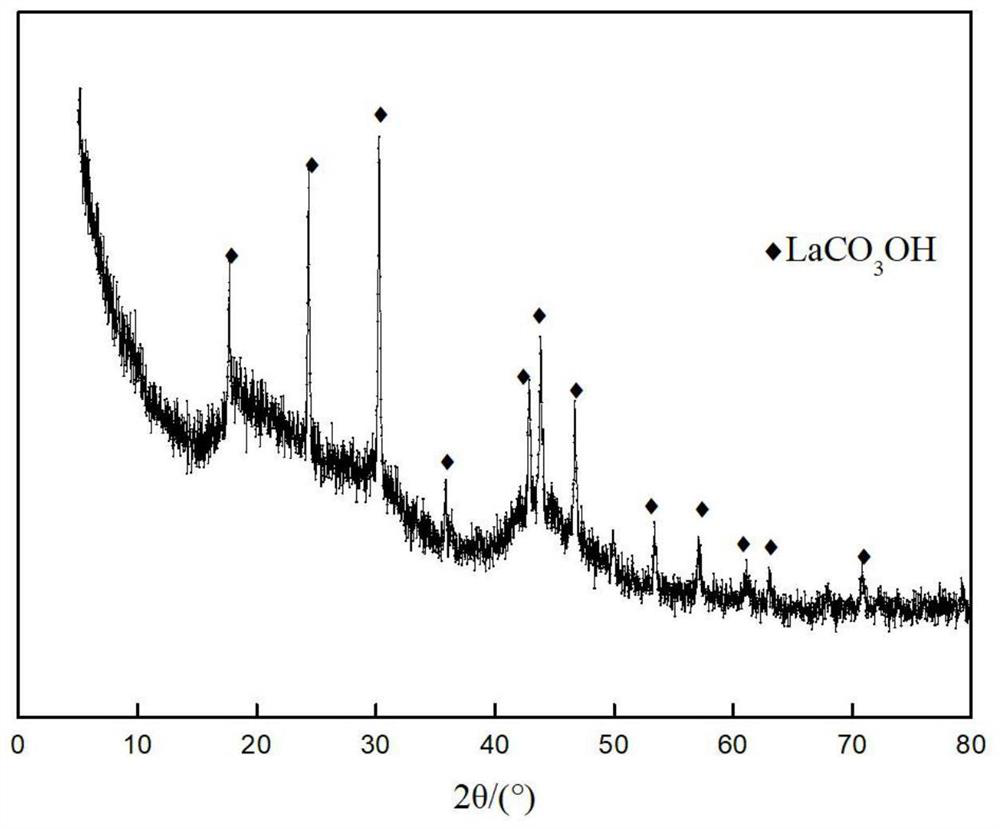

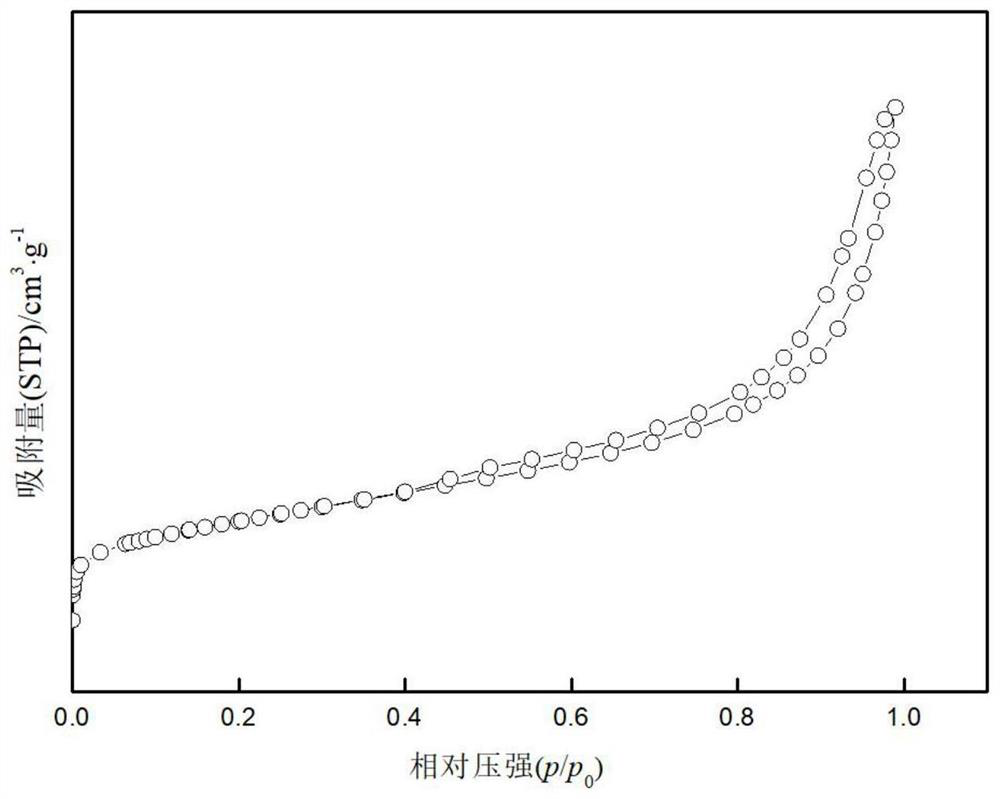

[0054] The adsorbent prepared in this embodiment is characterized by X-ray dif...

Embodiment 2

[0059] The porous adsorbent was prepared by a process different from that of Example 1 only in the hydrothermal reaction time, wherein the hydrothermal reaction time was 3 hours.

Embodiment 3

[0061] The porous adsorbent was prepared by a process different from that of Example 1 only in the hydrothermal reaction time, wherein the hydrothermal reaction time was 6 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com