Preparation method of micro-nano structured superhydrophobic coating based on nitrile rubber powder

A technology of superhydrophobic coating and nitrile rubber, which is applied in the field of coating and coating, can solve the problems of decreased hydrophobic performance and wear resistance restricting wide-scale application, and achieves low cost, wear resistance, green recyclability, and preparation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

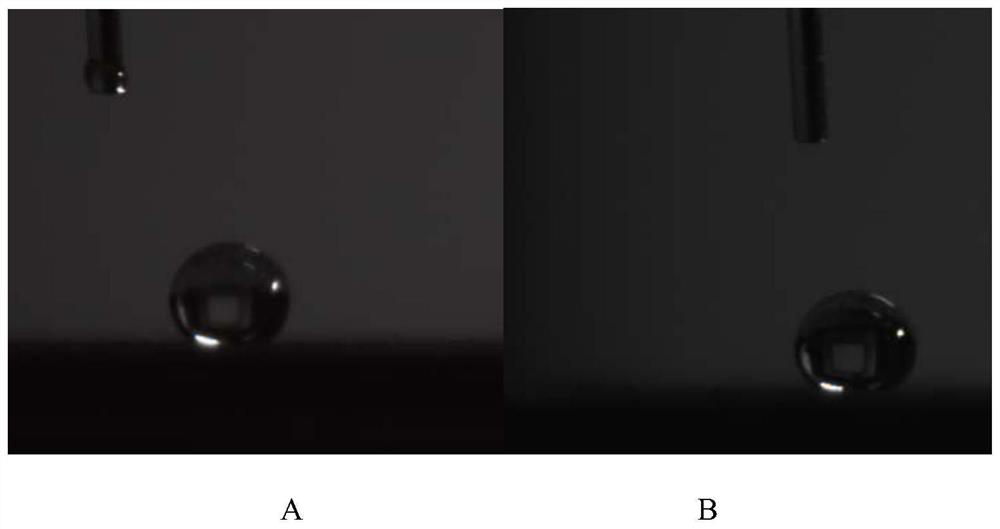

[0035] The preparation method of the described micro-nano structure superhydrophobic coating based on nitrile rubber powder construction, consists of the following steps:

[0036] Step 1. The preparation of adhesive: first prepare the epoxy resin that mass percent concentration is 40% and 20% respectively, then the epoxy resin that mass percent concentration is 40% and 20% and tetraethylene pentamine with solid Mix and stir for 5 minutes at a mass ratio of 11:1 to prepare Adhesives 1 and 2, respectively.

[0037] Step 2. Apply adhesive 1 (thickness 0.01mm) on the glass sheet, spray a layer of nitrile rubber powder (thickness 0.8mm) on the surface by dry spraying process, wait for 3 minutes, use 0.94-1.66m 3 A blower with an air volume of / min blows off the unbonded rubber powder particles on the surface, and the glass sheet is cured in an electric blast drying oven at a constant temperature of 80°C for 1 hour.

[0038] Step 3. Apply adhesive 2 (thickness 0.1mm) on the glass s...

Embodiment 2

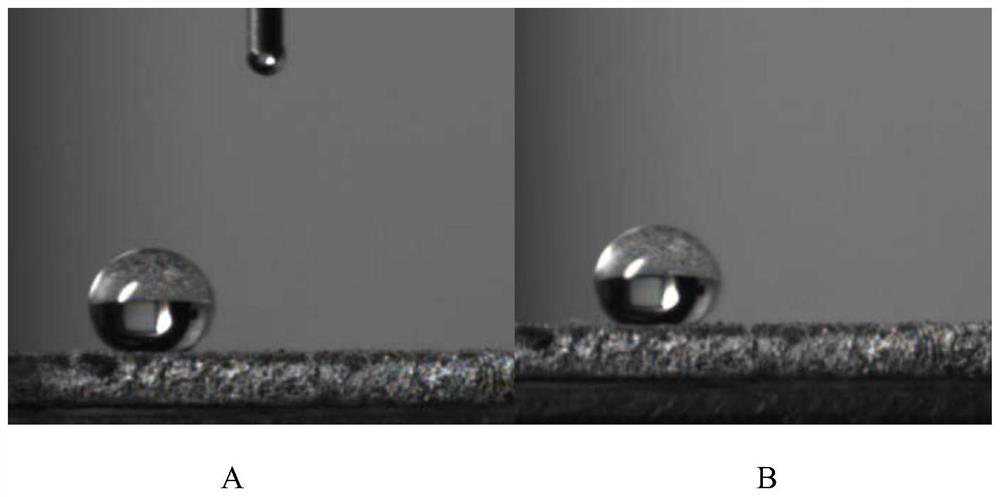

[0043] The difference between embodiment 2 and embodiment 1 is that the substrate used is stainless steel.

[0044]In step 2, the thickness of adhesive 1 is 0.01mm, and the thickness of nitrile rubber powder is 0.5mm

[0045] In step 3, the thickness of the adhesive 2 is 0.05 mm, and the thickness of the nitrile rubber powder is 0.5 mm.

[0046] The spraying thickness of step 4 is 0.01mm.

[0047] After curing, the contact angle measured by a contact angle tester was 159°, and the rolling angle was 3°. The coating was tested for wear resistance according to the American Society for Testing and Materials standard ASTM D 968-05 (the test for the determination of the wear resistance of organic coatings by falling sand abrasion method). The results showed that the coating was tested from a height of 5 kg of quartz sand After a 960 mm, 20 mm inner diameter conduit was dropped to perform an abrasion test on the coating. The static contact angle between the coating and water remai...

Embodiment 3

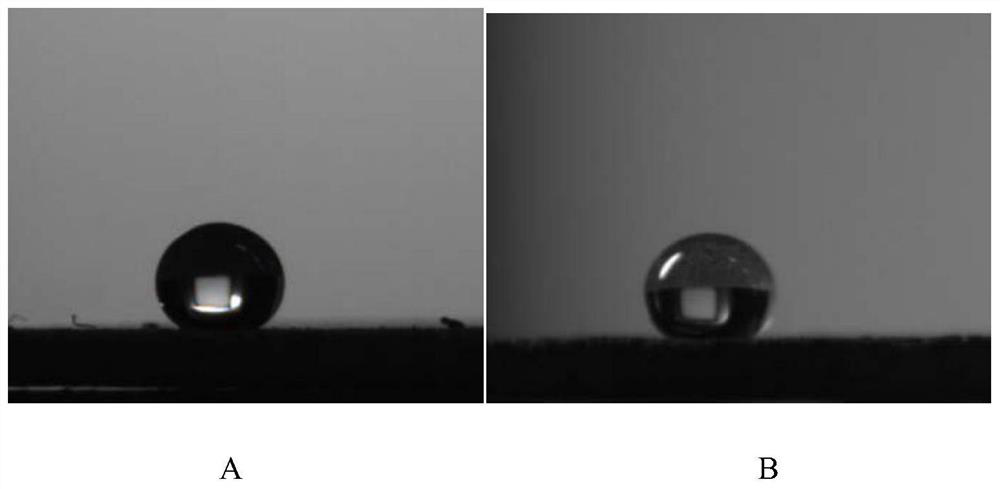

[0049] The difference between embodiment 3 and embodiment 1 is that the substrate used is a ceramic tile.

[0050] In step 2, the thickness of the adhesive 1 is 0.02 mm, and the thickness of the nitrile rubber powder is 1 mm.

[0051] In step 3, the thickness of the adhesive 2 is 0.2 mm, and the thickness of the nitrile rubber powder is 1 mm.

[0052] The spraying thickness of step 4 is 0.1mm.

[0053] After curing, the contact angle measured by a contact angle tester was 157°, and the rolling angle was 4°. The coating was tested for wear resistance according to the American Society for Testing and Materials standard ASTM D 968-05 (the test for the determination of the wear resistance of organic coatings by falling sand abrasion method). The results showed that the coating was tested from a height of 5 kg of quartz sand After a 960 mm, 20 mm inner diameter conduit was dropped to perform an abrasion test on the coating. The static contact angle between the coating and water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viewing angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com