Automatic unpacking and feeding method for granular materials

A technology of granular material and material bag, applied in the field of automatic unpacking and feeding of granular material, it can solve the problems of incomplete material falling, incomplete material falling, remaining residual material, etc., achieve stable and controllable feeding speed, and improve the level of automation , Improve the effect of feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

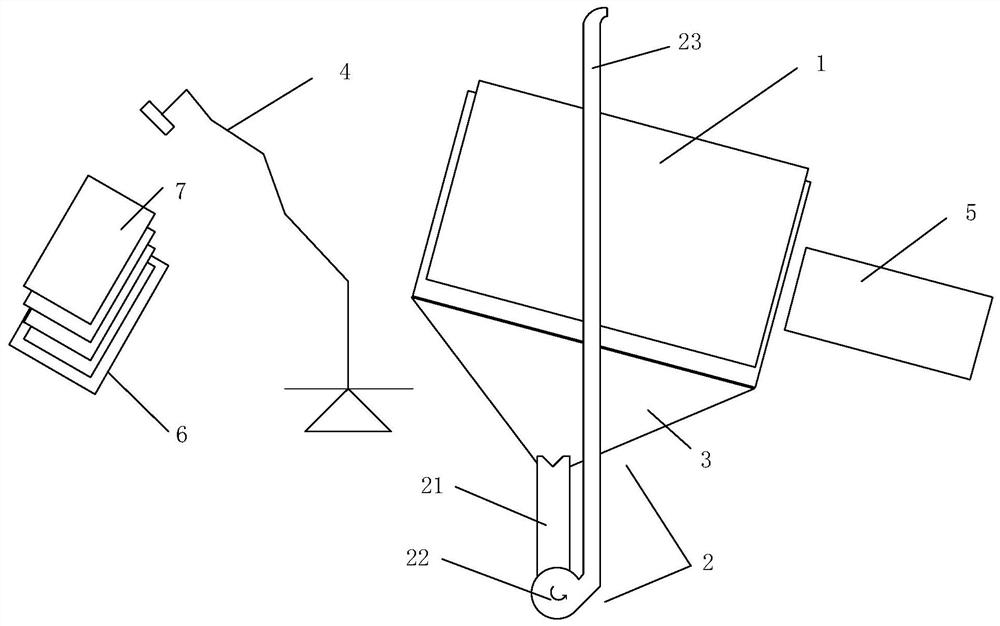

[0082] Such as figure 1 As shown, the present invention is based on an automatic unpacking and feeding device for granular materials, and the automatic unpacking and feeding device for granular materials includes: a bag moving machine 4, an unloading mechanism, a material collector 3, a feeding mechanism 2, a bag receiving mechanism 5, The material bag frame 6 and the controller, wherein the unloading mechanism includes a bag supporting mechanism 1, a cutting mechanism 10 and a folding mechanism 11.

[0083] combine Figure 14 As shown, the granular material automatic unpacking feeding method of the present invention comprises the following steps:

[0084] Starting device; transport the material bag from the material bag pile to the load-bearing support, so that the length direction of the material bag is parallel to the support cross bar;

[0085] In the center of the bottom of the material bag, cut the material bag from the length direction; insert the support frame with h...

Embodiment 2

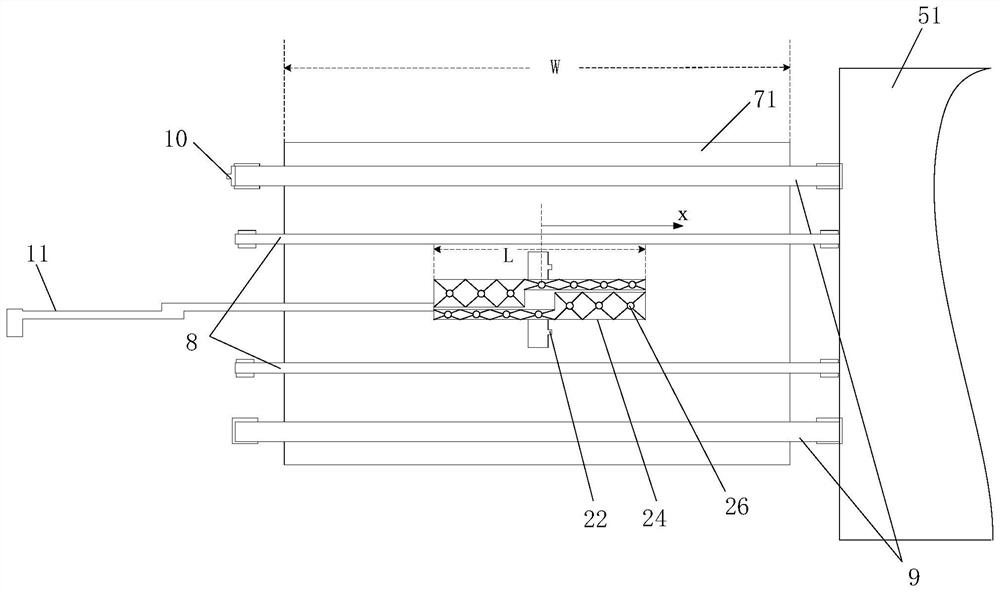

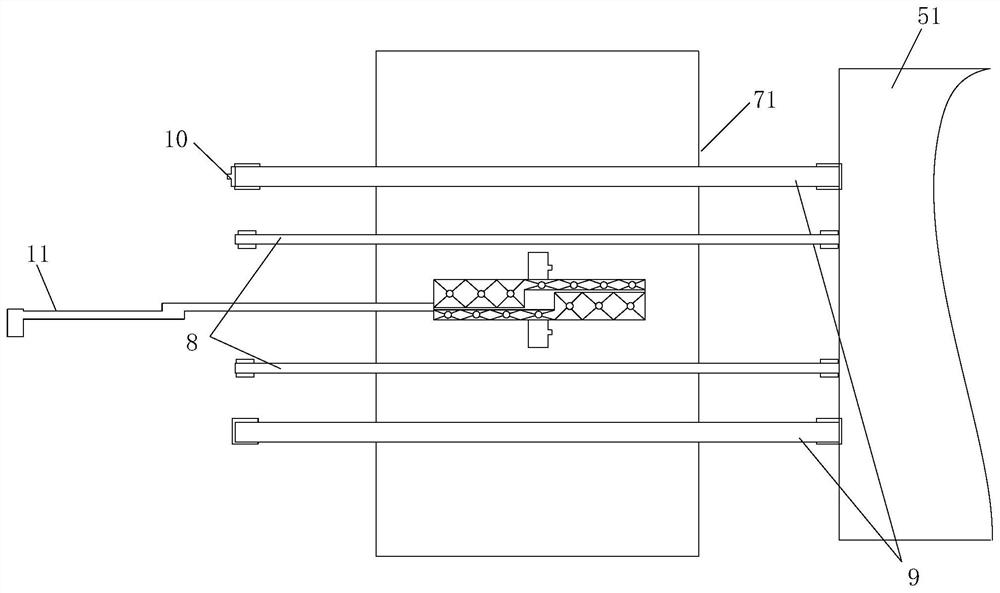

[0110] Different from Example 1, in this example, if Figure 2B As shown, when the bag 71 is transported to the first pole 9 and the second pole 8, its width direction is parallel to the poles.

[0111] The controller controls the cutting mechanism 10 to move the slider 14, and the blade 18 walks along the central axis of the two parallel bars of the second pole 8 to the other end, and cuts the material bag 71 from the width direction, and the granular material quickly passes through the cut. It falls, and at the same time, it drives the pockets on both sides of the cut to continue to separate to both sides. The controller controls the folding mechanism 11 folded on one side of the base to extend the support arm 21, move the support claw 24 to the center of the cutout of the material bag 71; insert the support claw 24 into the cutout in a closed state, and pass Two-way rotation of the supporting claw rotating shaft 22 to fold and unfold the material bag, during which, when th...

Embodiment 3

[0113] Such as Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 and Figure 12 As shown, different from Embodiment 1, in this embodiment, a crochet mechanism is assembled at the end of the claw 24 . The crochet mechanism includes a crochet needle 30 and a crochet needle part 40 that cooperates with it. When the claws are deployed to a position close to both ends, the crochet needle 30 will penetrate into the material bag 71 and then the material bag 71 will be folded and unfolded in the process of shaking the bag. Hook.

[0114] The crochet needle 30 includes a crochet needle seat 301, a magnetic crochet needle body 302 and a needle point 303 distributed sequentially from the bottom to the head. The crochet needle seat 301 is in an inverted T shape, and the crochet needle body 302 is an arc-shaped rod body and matches the inner wall of the curved pipe 403 of the crochet needle ligand 40. The transition part between the needle tip 303 and the hook body 302 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com