Recycled aggregate concrete and preparation method thereof

A technology of recycled aggregate and recycled coarse aggregate, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc. Low strength and other problems, to achieve the effect of reducing water absorption, improving compressive strength and impermeability, and improving connectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

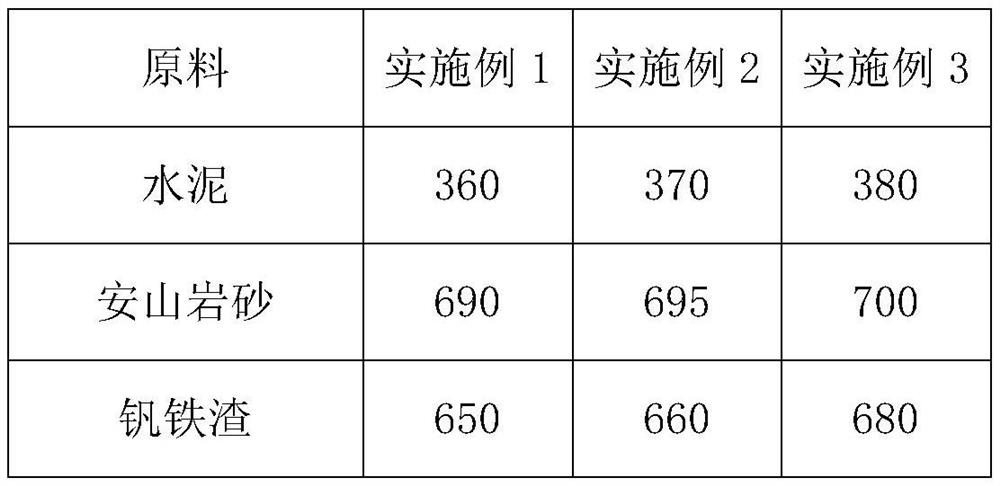

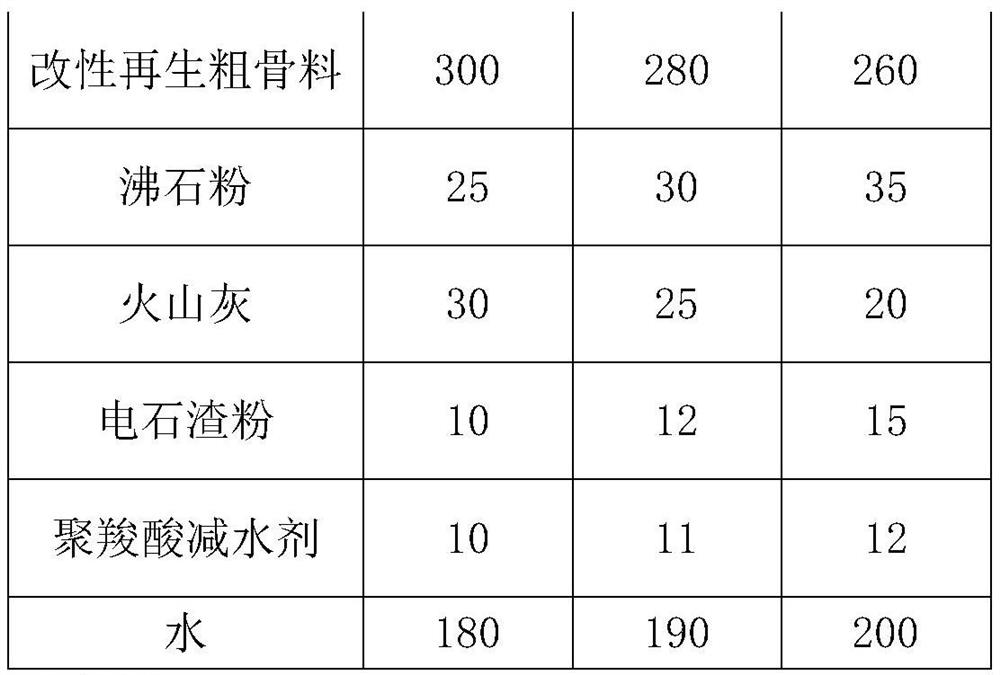

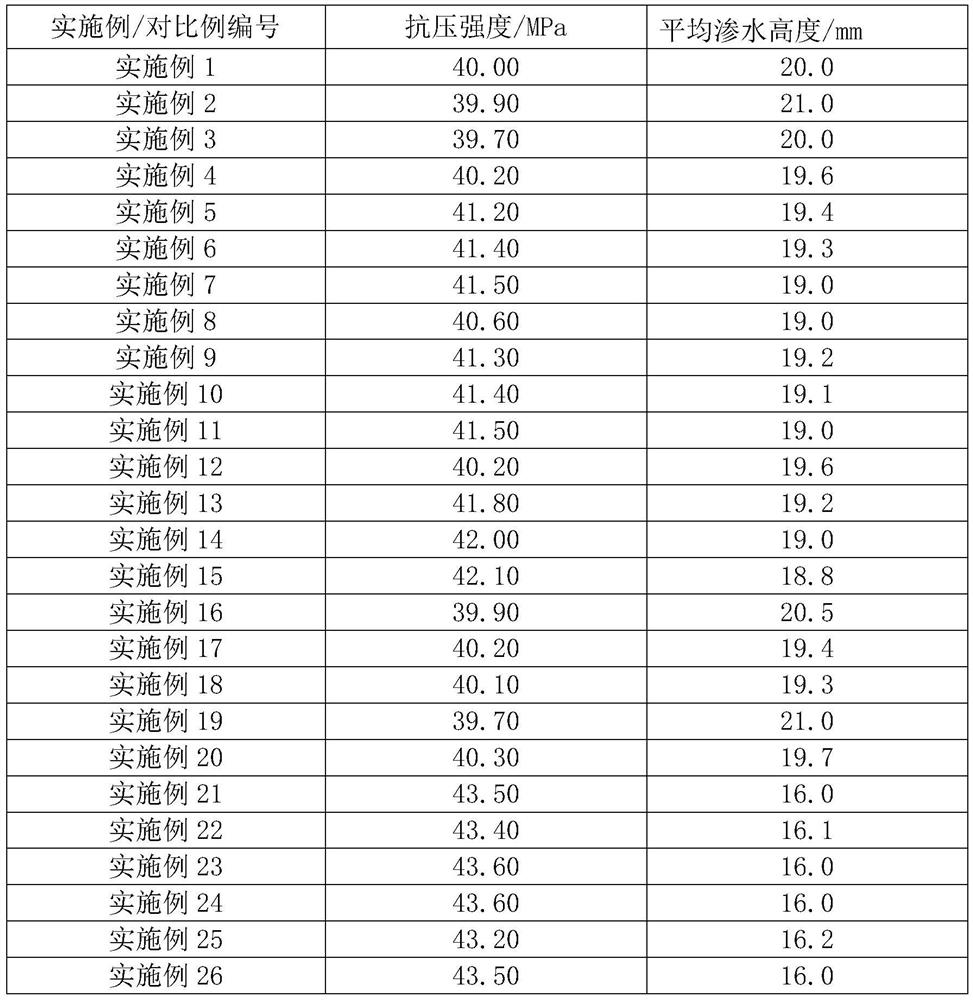

Examples

preparation example 1

[0044] Modified recycled coarse aggregate is prepared through the following steps:

[0045] Pretreatment, the waste concrete is crushed into coarse particles with a particle size of 5-20mm, and after being ball milled by a ball mill, 300kg of pretreated concrete particles are obtained;

[0046] Modification treatment, the pretreated concrete particles are put into the oxalic acid solution with a mass concentration of 70g / L, the oxalic acid solution is completely immersed in the pretreated concrete particles, stirred evenly, soaked for 1 hour, and the mixture is obtained;

[0047] Coupling treatment, add 30kg basalt fiber to the mixture, the length of basalt fiber is 2mm, the diameter is 10μm, stir evenly, then add 3kg silane coupling agent, silane coupling agent is vinyl tributyl ketoxime base silane, stirring reaction After 30 minutes, filter and dry to obtain modified recycled coarse aggregate.

preparation example 2

[0049] Modified recycled coarse aggregate is prepared through the following steps:

[0050] Pretreatment, crushing waste concrete into coarse particles with a particle size of 5-20mm, and after ball milling, 280kg of pretreated concrete particles are obtained;

[0051] Modification treatment, the pretreated concrete particles are put into the oxalic acid solution with a mass concentration of 65g / L, the oxalic acid solution is completely immersed in the pretreated concrete particles, stirred evenly, soaked for 1 hour, and the mixture is obtained;

[0052] Coupling treatment, add 35kg basalt fiber to the mixture, the length of basalt fiber is 2mm, the diameter is 10μm, stir evenly, then add 4kg silane coupling agent, silane coupling agent is aminopropyltriethoxysilane, stir reaction After 30 minutes, filter and dry to obtain modified recycled coarse aggregate.

preparation example 3

[0054] Modified recycled coarse aggregate is prepared through the following steps:

[0055] Pretreatment, the waste concrete is broken into coarse particles with a particle size of 5-20mm, and after being ball milled by a ball mill, 260kg of pretreated concrete particles are obtained;

[0056] Modification treatment, the pretreated concrete particles are put into the oxalic acid solution with a mass concentration of 60g / L, the oxalic acid solution is completely immersed in the pretreated concrete particles, stirred evenly, soaked for 1 hour, and the mixture is obtained;

[0057] Coupling treatment, add 40kg basalt fiber to the mixture, the length of basalt fiber is 2mm, the diameter is 10μm, stir evenly, then add 5kg silane coupling agent, silane coupling agent is aminopropyltriethoxysilane, stirring reaction After 30 minutes, filter and dry to obtain modified recycled coarse aggregate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com