Method for purifying liraglutide

A technology of liraglutide and carbon dioxide, applied in the field of purification, can solve problems such as uneconomical stationary phase, and achieve the effects of reducing operation, increasing recovery rate, and improving quality and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

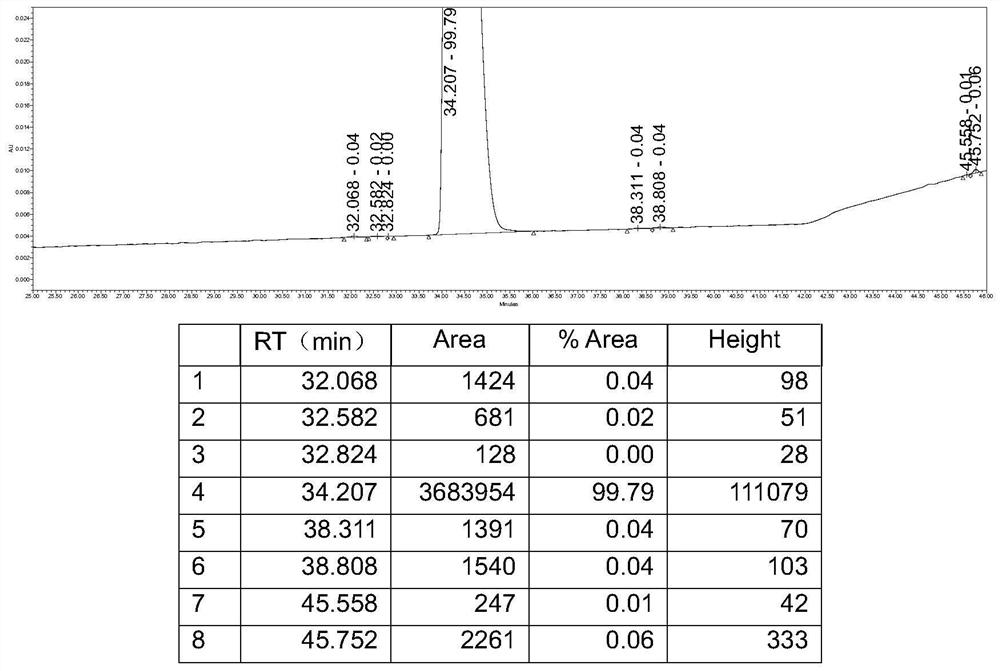

Embodiment 1

[0043] Example 1: Preparation of Liraglutide

[0044] The first step, liraglutide purification

[0045] Take 100.0 g of liraglutide crude peptide, containing 76.8 g of liraglutide, dissolve it in 4.5 L of ammonium bicarbonate (100 mM) solution, add 0.5 L of acetonitrile, filter at 0.45 μm, and divide the filtrate twice with 10 μm of C18 Preparative column (inner diameter 15cm, column length 30cm, filler pore diameter is ) purification, that is, 50.0 g per loading. First set mobile phase A as A1, 200mM ammonium bicarbonate + 50mM sodium bicarbonate, carbon dioxide to adjust the pH to 7.5, mobile phase A1 is in a sealed pressure tank, control the pressure at 0.1-0.5Mpa; mobile phase B is acetonitrile. The flow rate is 620mL / min, the elution gradient is 40%B-55%B (100min), the mobile phase A1 and B are controlled at 25°C, the column temperature is 25°C, and when the elution reaches 100min, stop the flow rate and change the elution conditions .

[0046] At this time, the mobi...

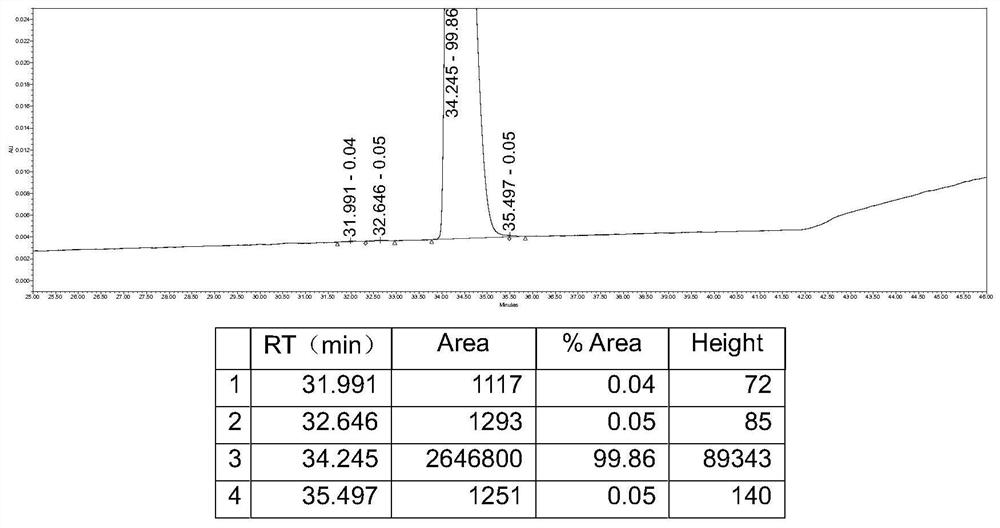

Embodiment 2

[0049] Example 2: Preparation of Liraglutide

[0050] The first step, liraglutide purification

[0051] Take 100.0 g of liraglutide crude peptide, containing 76.8 g of liraglutide, dissolve it in 4.5 L of sodium bicarbonate (80 mM) solution, add 0.5 L of acetonitrile, filter at 0.45 μm, and divide the filtrate twice with 10 μm of C8 Preparative column (inner diameter 15cm, column length 30cm, filler pore diameter is ) purification, that is, 50.0 g per loading. First set mobile phase A as A1, 100mM ammonium bicarbonate + 100mM potassium bicarbonate, carbon dioxide to adjust the pH to 7.5, mobile phase A1 is in a sealed pressure tank, control the pressure at 0.1-0.5Mpa; mobile phase B is acetonitrile. The flow rate is 620mL / min, the elution gradient is 40%B-55%B (100min), the mobile phase A1 and B are controlled at 25°C, the column temperature is 25°C, and when the elution reaches 100min, stop the flow rate and change the elution conditions .

[0052] At this time, switch m...

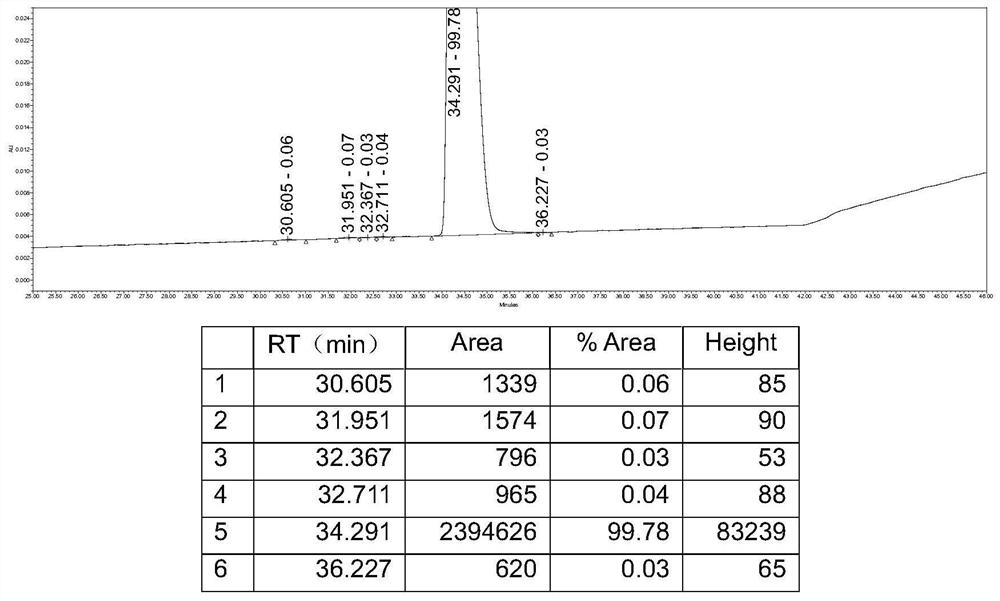

Embodiment 3

[0055] Example 3: Preparation of Liraglutide

[0056] The first step, liraglutide purification

[0057] Take 100.0 g of liraglutide crude peptide, containing 76.8 g of liraglutide, dissolve it in 4.5 L of potassium bicarbonate (200 mM) solution, add 0.5 L of acetonitrile, filter at 0.45 μm, and prepare a column with 10 μm of C4 (inner diameter 15cm, the column length is 30cm, and the packing pore diameter is ) was purified in two steps. First set mobile phase A as A1, 100mM ammonium bicarbonate + 100mM potassium bicarbonate, carbon dioxide to adjust pH to 7.50, mobile phase A1 is in a sealed pressure tank, control pressure at 0.1-0.5Mpa; mobile phase B is acetonitrile. The flow rate is 620mL / min, the elution gradient is 37%B-45%B (100min), the mobile phase A1 and B are controlled at 25°C, the column temperature is 25°C, and when the elution reaches 100min, stop the flow rate and change the elution conditions .

[0058] At this time, switch mobile phase A to A2, 50mM ammon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com