Degradable expanded polymer grouting material as well as preparation method and application thereof

A polymer water-absorbing, high-molecular polymer technology, applied in coatings and other directions, can solve problems such as difficult to achieve water inrush plugging in karst areas, lack of pertinence in the governance system, complex water inrush in karst areas, etc., to achieve easy industrialization, The effect of low price and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

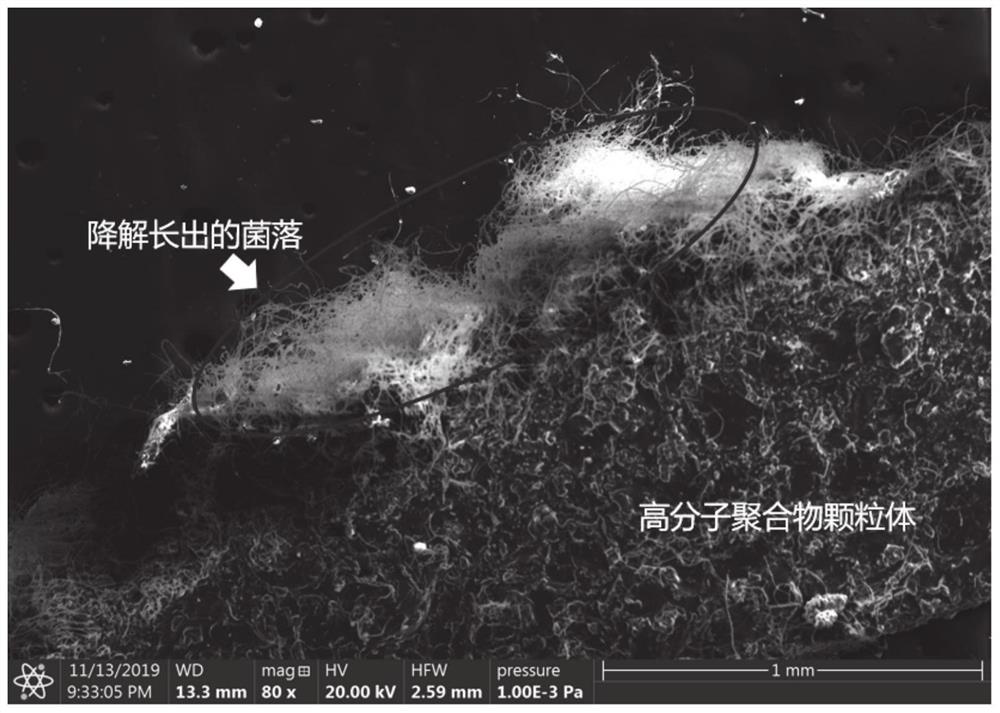

Image

Examples

preparation example Construction

[0028] In a first aspect, the present invention provides a method for preparing a degradable polymer granule A, comprising the following steps:

[0029] Using a mixed solution of hydrogen peroxide and sulfuric acid to modify the cellulose-based high-molecular water-absorbing resin or natural polymer powder in a water bath to obtain a modified cellulose-based high-molecular water-absorbing resin or a modified natural polymer;

[0030] Put the modified cellulose-based polymer water-absorbing resin or modified natural polymer into water, and heat and activate it in a water bath;

[0031] Mix the crosslinking agent, acrylic acid solution and the active substance containing the hydrophilic group, and polymerize to obtain the precursor;

[0032] removing air from the activation system after heating and activation in a water bath, and adding the precursor and initiator to it, heating and reacting to obtain a colloidal polymer;

[0033] Grinding the colloidal polymer, and then sprayi...

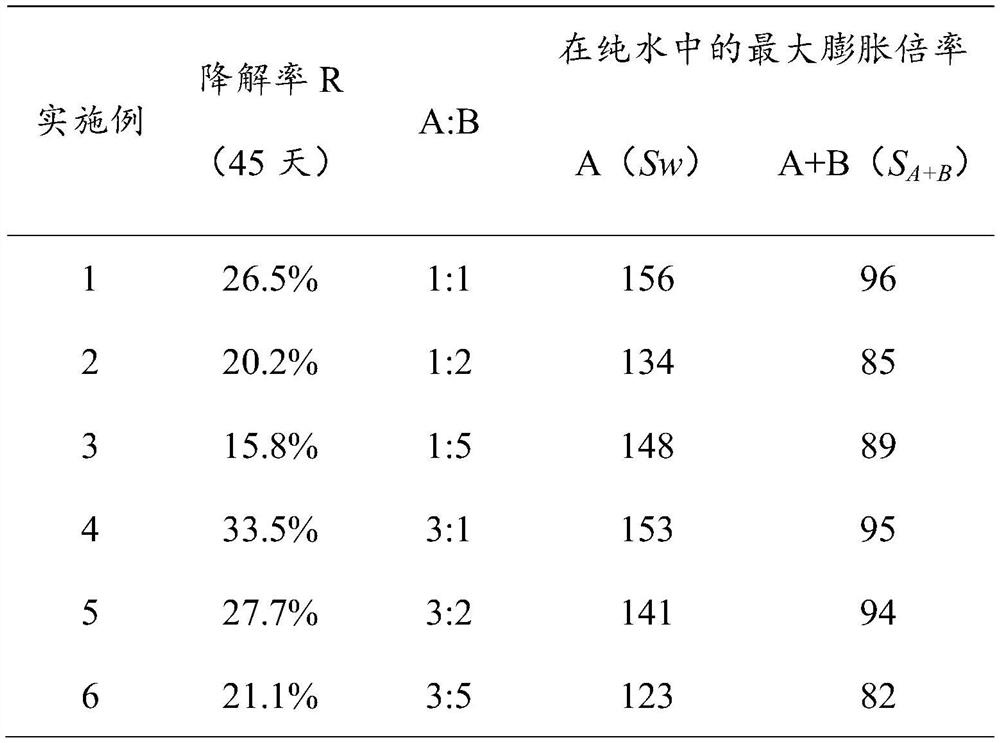

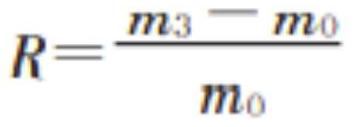

Embodiment 1

[0082] A preparation of a degradable ultra-high expansion grouting material for efficient plugging of karst pipeline type water gushing, comprising the following steps:

[0083] A: Add 10g of dried bamboo chips of 100-200 mesh to 100ML 4wt% H 2 o 2 / 2wt%H 2 SO 4 In the mixed solution, the mixed solution after adding bamboo chips was placed in a 70°C pot and heated in a water bath for 3 hours, the reactant was washed with deionized water until neutral, and dried in a vacuum drying oven at 80°C for 12 hours to obtain modified bamboo chips .

[0084] B: Put the modified bamboo chips prepared in step A into 10 mL of deionized water, then put it into a pot, set up magnetic stirring and condensing reflux, heat in a water bath at 80°C, and activate for 1 hour.

[0085] C: Add 0.3 g of polyethylene glycol diglycidyl ether to 100 g of acrylic acid solution with a concentration of 20%, then add 0.5 g of polyvinyl alcohol, and stand at 0° C. for 1 h to form a precursor.

[0086] D: ...

Embodiment 2

[0090] A preparation of a degradable ultra-high expansion grouting material for efficient plugging of karst pipeline type water gushing, comprising the following steps:

[0091] A: Add 20g of dried bamboo chips of 100-200 mesh to 500ML 8wt% H 2 o 2 / 6wt%H 2 SO 4 In the mixed solution, the mixed solution after adding bamboo chips was placed in a 70°C pot and heated in a water bath for 3 hours, the reactant was washed with deionized water until neutral, and dried in a vacuum drying oven at 80°C for 12 hours to obtain modified bamboo chips .

[0092] B: Put the modified bamboo chips prepared in step A into 20mL of deionized water, then put it into a pot, set up magnetic stirring and condensing reflux, heat in a water bath at 80°C, and activate for 1 hour.

[0093] C: Add 1.8 g of polyethylene glycol diglycidyl ether to 100 g of acrylic acid solution with a concentration of 20%, then add 1 g of starch solution, and stand at 25° C. for 1 h to form a precursor.

[0094] D: After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com