Method for producing biodiesel by using red tide algae and algicidal bacteria

A technology of biodiesel and red tide algae, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problem of high cost of cell crushing and mechanical crushing, and achieve the goals of simplifying the process of splitting algae, saving production costs, and saving energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

[0032] 1. Materials and methods

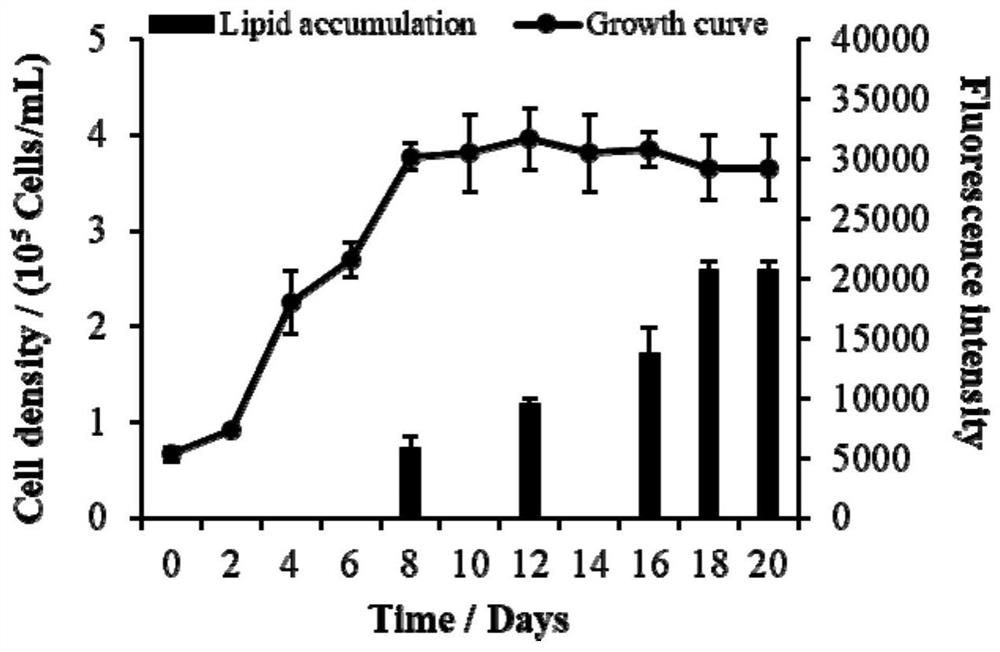

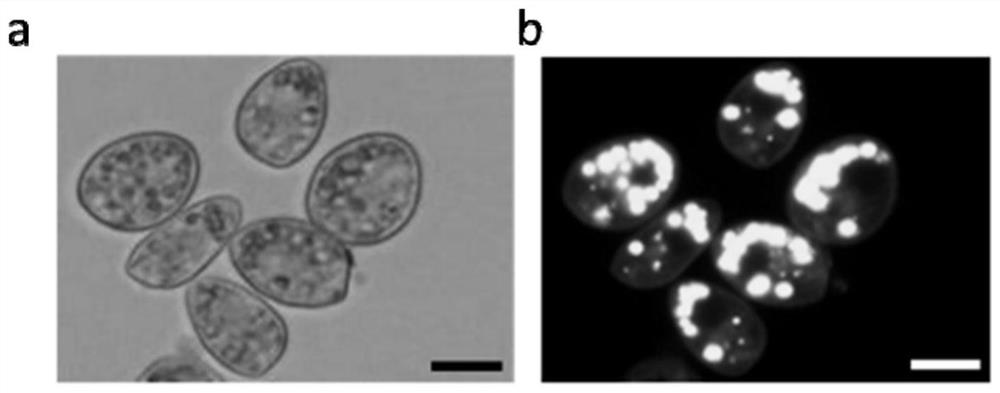

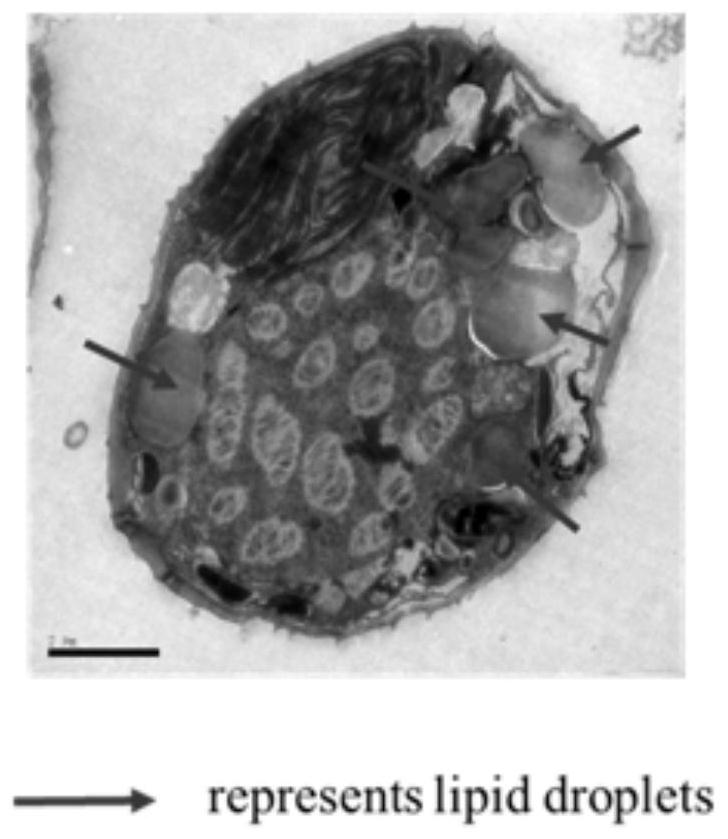

[0033] 1.1 algae species and cultivation: the algae species used in the embodiment of the present invention is Prorocentrum donghaiense (Prorocentrum donghaiense), which is preserved in the State Key Laboratory of Offshore Marine Environmental Science of Xiamen University (strain number: 364, separated from the Yangtze Estuary of the East China Sea). Buy. Cultivate in f / 2 liquid medium with an inoculum of 4%, and grow at room temperature 20-27°C and light intensity 50-200μmoL photons m -2 the s -1 Cultured under light and dark (12h / 12h) conditions.

[0034] Table 1 Main components of f / 2 medium

[0035]

[0036] 1.2 Algae-dissolving strains and cultivation:

[0037] The algicidal strain Paracoccus sp.Y42 was isolated from the Zhangzhou Mangrove National Nature Reserve and was preserved in the Guangdong Microbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com