Treatment method for synergistically solidifying waste incineration fly ash and evaporation concentrated solution obtained after waste membrane treatment

A technology for incinerating fly ash and evaporating concentrated liquid from waste is applied in chemical instruments and methods, multi-stage water/sewage treatment, heating water/sewage treatment, etc. Achieve the effect of solving the problem of secondary pollution, reducing the processing burden and solving the problem of insufficient strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

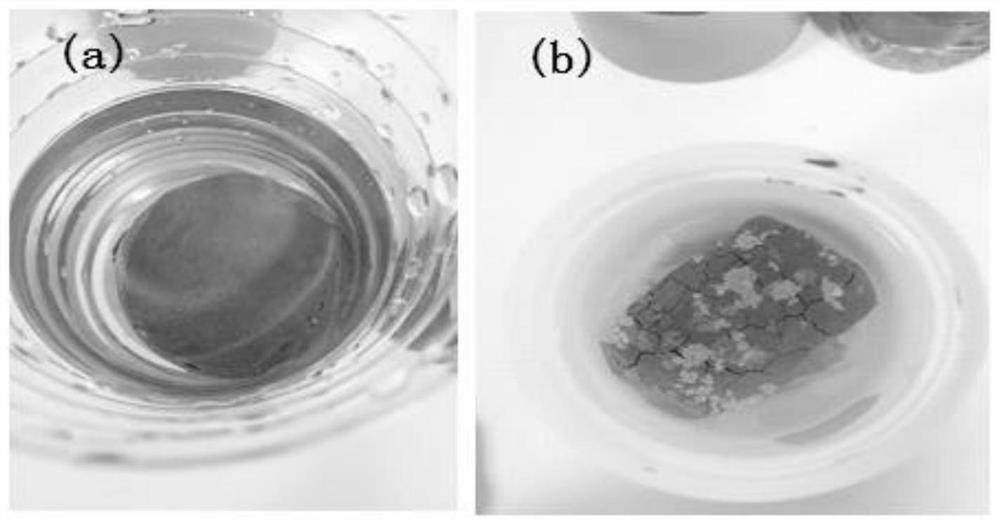

Image

Examples

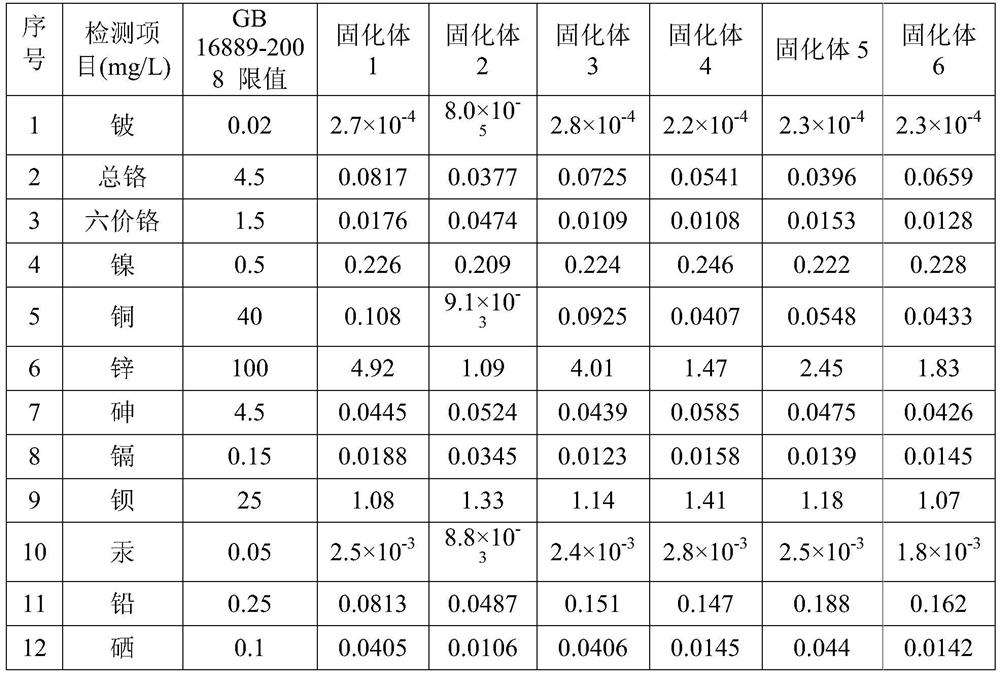

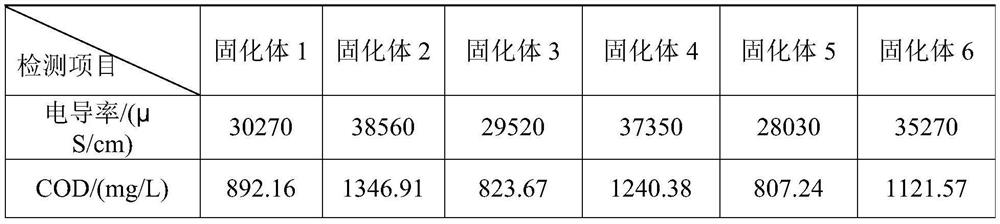

Embodiment 1

[0038] A treatment method for co-solidifying waste incineration fly ash and evaporated concentrate after waste film treatment, comprising the following steps:

[0039] (1) Evaporating and concentrating the waste with a water content of 90% after membrane treatment, performing centrifugal dehydration and low-temperature drying until the water content drops to 35% to 40%, to obtain a mother liquor. TDS in this mother liquor is 600,000 mg / L.

[0040](2) According to the amount of asphalt being 1% of the weight of waste incineration fly ash, place the asphalt in mixer A and heat at 100°C until a paste-like asphalt is formed, stir for 5 minutes, and add the mother liquor obtained in step S1 (the amount of mother liquor is 12.5% of the weight of waste incineration fly ash), and stirred for 20 minutes until the asphalt wraps 95% of the mother liquor to form a slurry mixture.

[0041] According to the amount of the curing agent being 17.5% of the weight of the waste incineration fl...

Embodiment 2

[0048] A treatment method for co-solidifying waste incineration fly ash and evaporated concentrate after waste film treatment, comprising the following steps:

[0049] (1) According to the amount of pitch being 1% of the weight of the waste incineration fly ash, the pitch is placed in the A mixer and heated at 100°C until it forms a paste pitch, stirred for 5 minutes, and added the mixture obtained in Example 1 The mother liquor (the amount of the mother liquor is 11.1% of the weight of the waste incineration fly ash) was stirred for 20 minutes until the bitumen covered 95% of the mother liquor to form a slurry mixture.

[0050] According to the amount of the curing agent being 18.9% of the weight of the waste incineration fly ash, the waste incineration fly ash and the curing agent (specifically, sulphoaluminate cement) were mixed in the B mixer and stirred for 5 minutes to form a solid mixture.

[0051] (2) The slurry mixture obtained in step (1) is added to the solid mixtur...

Embodiment 3

[0057] A treatment method for co-solidifying waste incineration fly ash and evaporated concentrate after waste film treatment, comprising the following steps:

[0058] (1) According to the amount of pitch being 1% of the weight of the waste incineration fly ash, the pitch is placed in the A mixer and heated at 100°C until it forms a paste pitch, stirred for 5 minutes, and added the mixture obtained in Example 1 The mother liquor (the amount of the mother liquor is 10% of the weight of the waste incineration fly ash) was stirred for 20 minutes until the bitumen covered 95% of the mother liquor to form a slurry mixture.

[0059] According to the amount of the curing agent being 20% of the weight of the waste incineration fly ash, the waste incineration fly ash and the curing agent (specifically sulphoaluminate cement) were mixed in the mixer B, and stirred for 5 minutes to form a solid mixture.

[0060] (2) The slurry mixture obtained in step (1) is added to the solid mixture ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com