Salt-containing wastewater treatment system and treatment process thereof

A salt-containing wastewater treatment system technology, applied in water/sewage treatment, water treatment parameter control, water/sewage multi-stage treatment, etc. The service life of fouling blockage and other issues can reduce the risk of fouling blockage, reduce COD, and improve the treatment effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

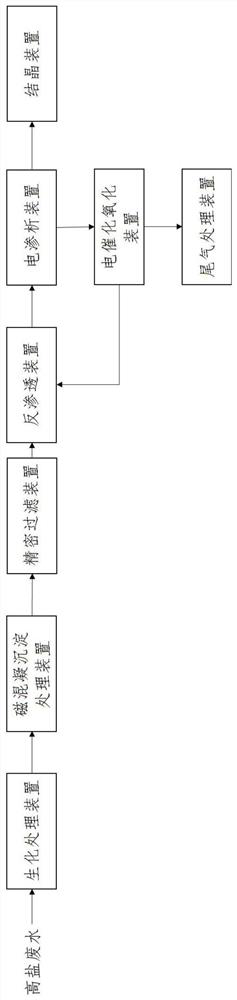

[0030] Please refer to figure 1 As shown, the embodiment of the present invention discloses a saline wastewater treatment system. The disclosed saline wastewater treatment system includes an electrodialysis device and an electrocatalytic oxidation device; The water end is connected, and the electrodialysis device is used for the electrodialysis separation of salty wastewater, and the separated electrodialysis desalinated water is sent to the electrocatalytic oxidation device for electrocatalytic oxidation treatment.

[0031] Among them, firstly, the electrodialysis device is driven by an external electric field to separate and treat the saline wastewater by using the selective permeability of the ion exchange membrane, so as to obtain the electrodialysis concentrated water containing salt and the electrodialysis desalination water containing organic matter. The removal of salt in saline wastewater, and the removal effect of salt is better than that of reverse osmosis membrane;...

Embodiment 2

[0040] Based on the saline wastewater treatment system in Example 1; correspondingly, the embodiment of the present invention discloses a saline wastewater treatment process; wherein, taking the wastewater produced by a coal chemical plant as an example, the COD concentration is about 800mg / L, The concentration of ammonia nitrogen is about 200 mg / L; specifically, the following processing steps are included:

[0041] Biochemical treatment step: transport the wastewater to be treated to a biochemical treatment device for pretreatment, so that the COD concentration in the wastewater can be reduced to about 80mg / L through biochemical reactions;

[0042] Magnetic coagulation sedimentation treatment steps: transport the wastewater pretreated by biochemical reaction to the magnetic coagulation sedimentation device for magnetic coagulation sedimentation treatment to further reduce the content of COD and total suspended solids; among them, in the process of magnetic coagulation sediment...

Embodiment 3

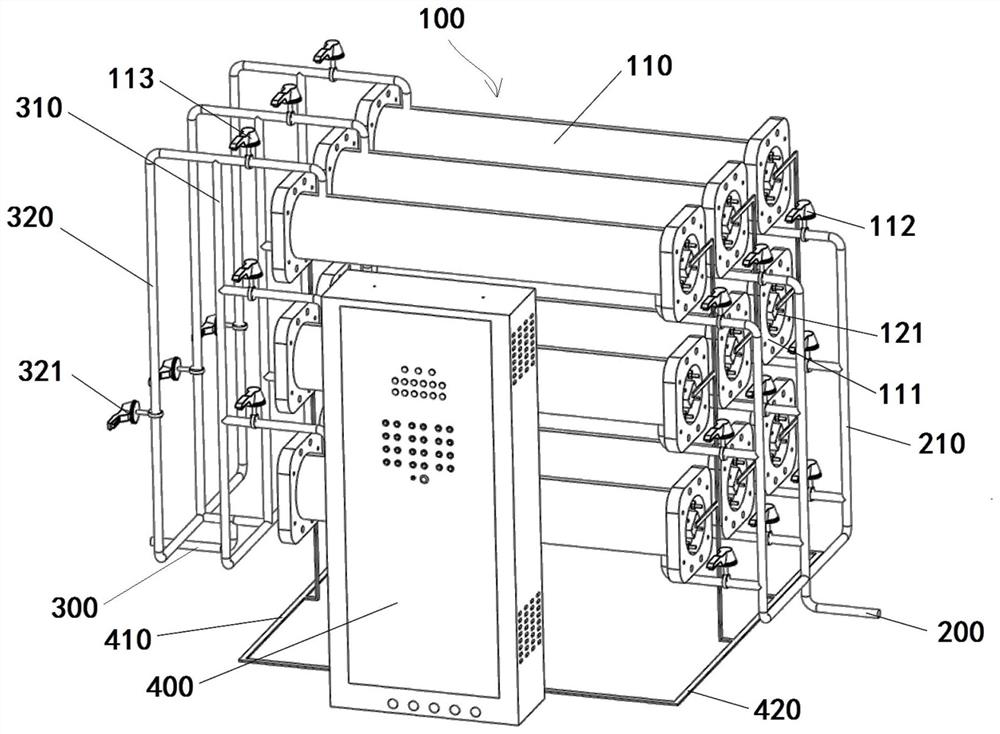

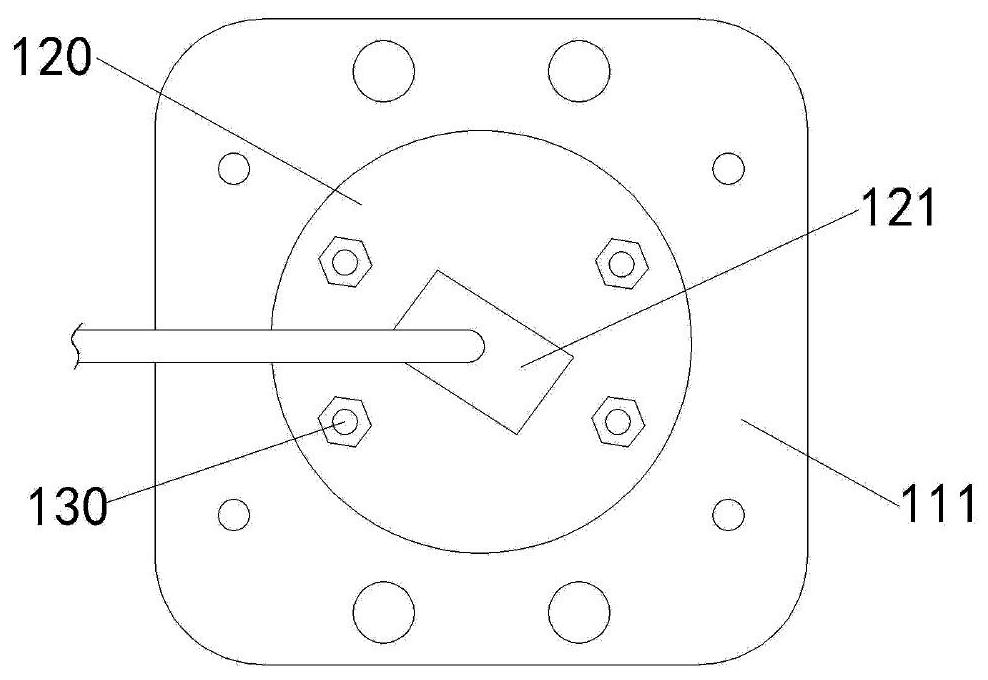

[0048] Please refer to figure 2 and image 3 As shown, the embodiment of the present invention discloses an electrocatalytic oxidation device, which is applicable to the saline wastewater treatment system and treatment process disclosed in the present invention.

[0049] The electrocatalytic oxidation treatment device disclosed in the embodiment of the present invention includes at least two electrolytic cells 100 arranged in parallel between the main water inlet 200 and the main water outlet 300, and the main water inlet 200 is connected to the main water outlet 300 through the electrolytic cell 100, namely The water inlet end of each electrolytic cell 100 is respectively connected with the water inlet main pipe 200, and the water outlet end of each electrolytic cell 100 is respectively connected with the water outlet main pipe 300; meanwhile, the water inlet main pipe 200 is used for connecting the water outlet end of the magnetic coagulation sedimentation device, The wast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com