Negative electrode dispersing agent and lithium ion battery containing dispersing agent

A dispersant and molecular weight technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve the problem of low viscosity of negative electrode dispersant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0088] [Preparation method of dispersant]

[0089] The present invention also provides the preparation method of above-mentioned dispersant, described method comprises the steps:

[0090] (1) sodium carboxymethyl cellulose is dissolved in a solvent to obtain a uniform sodium carboxymethyl cellulose solution;

[0091] (2) in the sodium carboxymethyl cellulose solution of step (1), add the first pH regulator, react, obtain the sodium carboxymethyl cellulose solution of hydroxyl protonation;

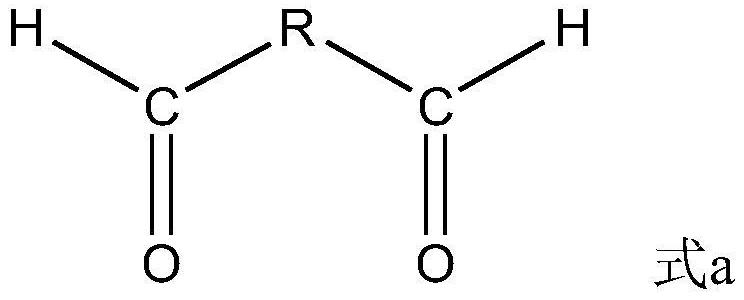

[0092] (3) continue to add the compound shown in formula a, react, add the second pH adjuster to prepare the dispersant; or,

[0093] (1) sodium carboxymethyl cellulose is dissolved in a solvent to obtain a uniform sodium carboxymethyl cellulose solution;

[0094] (2') in the sodium carboxymethyl cellulose solution of step (1), add the second pH regulator, react, obtain the sodium carboxymethyl cellulose solution of hydroxyl deprotonation;

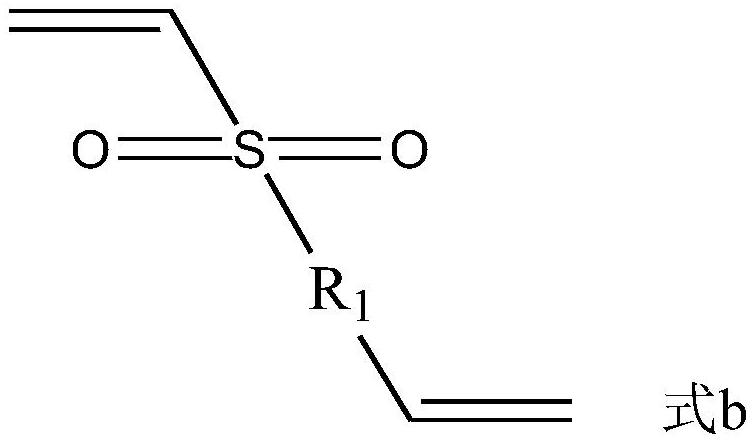

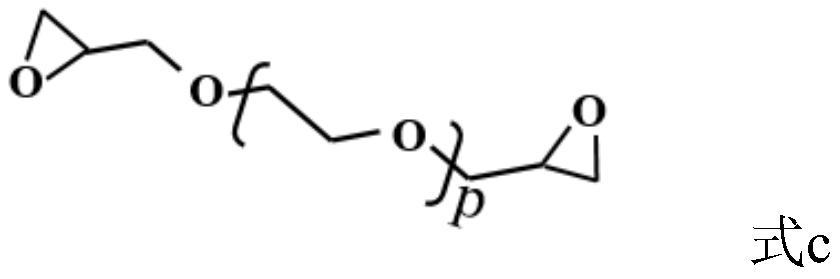

[0095] (3') continue to add at least one of th...

Embodiment approach

[0147] According to an embodiment of the present invention, the preparation method of the negative electrode sheet includes the following steps:

[0148] (1) Negative electrode active material, conductive agent, binding agent and above-mentioned dispersant are mixed uniformly, obtain negative electrode slurry;

[0149] (2) Coating the negative electrode slurry on the surface of the negative electrode current collector, and obtaining the negative electrode sheet after baking.

[0150] [Application of Negative Electrode]

[0151] The present invention also provides the application of the above-mentioned negative electrode sheet in a lithium ion battery.

[0153] As mentioned above, the present invention provides a lithium-ion battery, which includes the above-mentioned negative electrode sheet.

[0154] According to an embodiment of the present invention, the lithium ion battery further includes a positive pole piece, a separator and an electrol...

Embodiment 1

[0171] Preparation of cross-linked CMC:

[0172] 1) Weigh 10 parts by mass of CMC (1) with a degree of substitution of 0.82, add it to a reaction flask, then add 250 parts by mass of deionized water, and mechanically stir for 4 hours at a rotation speed of 500 rpm to obtain a uniform CMC solution;

[0173] 2) Add 0.1mol / L hydrochloric acid to the above CMC solution, adjust the pH to 5, stir at 500rpm, and react at 25°C for 1h to obtain the CMC solution;

[0174] 3) Add 0.02 parts by mass of glutaraldehyde to the CMC solution in step 2), stir, react at 40°C for 3 hours, then lower to room temperature, add 0.5mol / L sodium carbonate to adjust the pH to 7, and obtain a cross-linked CMC solution;

[0175] 4) Add 400 parts by mass of ethanol to the cross-linked CMC solution obtained in step 3 to separate out the modified CMC molecules, filter with suction, and dry the filter cake at 60° C. for 12 hours in a blast drying oven, and then in a vacuum drying oven for 50 Dry at ℃ for 10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com