Glass microsphere filled polypropylene composition and preparation method thereof

A polypropylene composition and glass microsphere technology, applied in the field of glass microsphere filled polypropylene composition and its preparation, can solve the problem of limited strength and impact resistance, poor interface bonding ability between glass microspheres and polypropylene, and compatibility. It can improve the mechanical properties, enhance the interfacial bonding ability, and have excellent mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

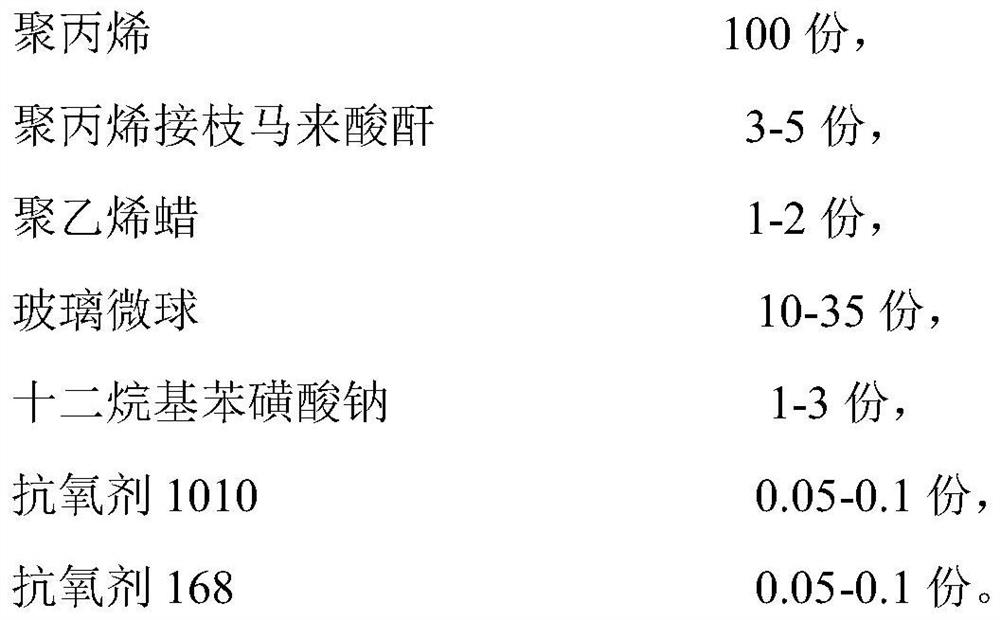

Method used

Image

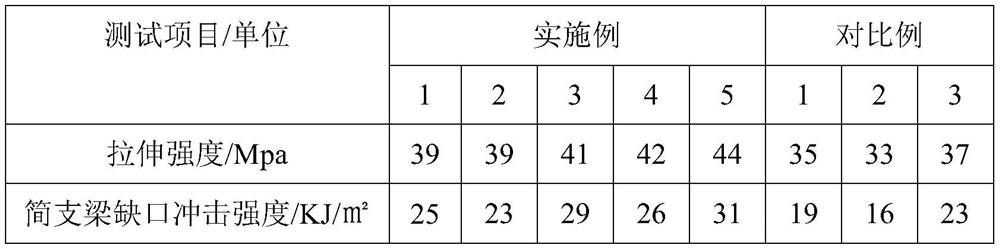

Examples

Embodiment 1

[0029] (1) Add 1 part of polyethylene wax, 10 parts of glass microspheres, and 1 part of sodium dodecylbenzenesulfonate into a mixer for mixing. The mixing temperature is 100°C, the mixing speed is 60 rpm, and the mixture is mixed for 2 minutes; After cooling down to normal temperature, add 100 parts of polypropylene, 3 parts of polypropylene grafted maleic anhydride, 0.05 part of antioxidant 1010, and 0.05 part of antioxidant 168 at a mixing speed of 100 rpm for 5 minutes to obtain a mixture.

[0030] (2) Add the mixture from the feeding port of the twin-screw extruder, extrude and granulate, and prepare the polypropylene composition.

[0031] In a further scheme, in step (2), the processing technology of the twin-screw extruder is as follows: the temperature of the first zone is 180°C, the temperature of the second zone is 200°C, the temperature of the third zone is 220°C, the temperature of the fourth zone is 220°C, and the temperature of the fifth zone is 220°C , the tempe...

Embodiment 2

[0033] (1) Add 2 parts of polyethylene wax, 35 parts of glass microspheres, and 3 parts of sodium dodecylbenzenesulfonate into a mixer for mixing. The mixing temperature is 120°C, the mixing speed is 100 rpm, and mixed for 1 minute; After cooling down to normal temperature, add 100 parts of polypropylene, 5 parts of polypropylene grafted maleic anhydride, 1 part of antioxidant 1010, and 1 part of antioxidant 168 at a mixing speed of 60 rpm for 3 minutes to obtain a mixture.

[0034] (2) Add the mixture from the feeding port of the twin-screw extruder, extrude and granulate, and prepare the polypropylene composition.

[0035] In a further scheme, in step (2), the processing technology of the twin-screw extruder is: the temperature of the first zone is 200°C, the temperature of the second zone is 220°C, the temperature of the third zone is 230°C, the temperature of the fourth zone is 230°C, and the temperature of the fifth zone is 230°C , the temperature in the six zones is 230°...

Embodiment 3

[0037] (1) Add 1 part of polyethylene wax, 15 parts of glass microspheres, and 2 parts of sodium dodecylbenzenesulfonate into a mixer for mixing. The mixing temperature is 120° C., the mixing speed is 80 rpm, and the mixture is mixed for 2 minutes; After cooling down to normal temperature, 100 parts of polypropylene, 4 parts of polypropylene grafted maleic anhydride, 0.08 part of antioxidant 1010, 0.08 part of antioxidant 168 were added at a mixing speed of 100 rpm for 4 minutes to obtain a mixture.

[0038] (2) Add the mixture from the feeding port of the twin-screw extruder, extrude and granulate, and prepare the polypropylene composition.

[0039] In a further solution, in step (2), the processing technology of the twin-screw extruder is as follows: the temperature of the first zone is 180°C, the temperature of the second zone is 210°C, the temperature of the third zone is 220°C, the temperature of the fourth zone is 220°C, and the temperature of the fifth zone is 220°C , t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com