Method for treating aramid fiber doped modified cellulose insulation paper by plasma

A plasma and aramid fiber technology, which is applied in the fields of synthetic cellulose/non-cellulose material pulp/paper, fiber raw material processing, papermaking, etc., can solve the problem of poor interface binding ability between aramid fiber 1313 and natural cellulose, composite insulating paper Low mechanical properties, uneven distribution of electric field, etc., to achieve the effect of increasing breakdown field strength and discharge initiation voltage, improving interface incompatibility, and improving uneven distribution of electric field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below.

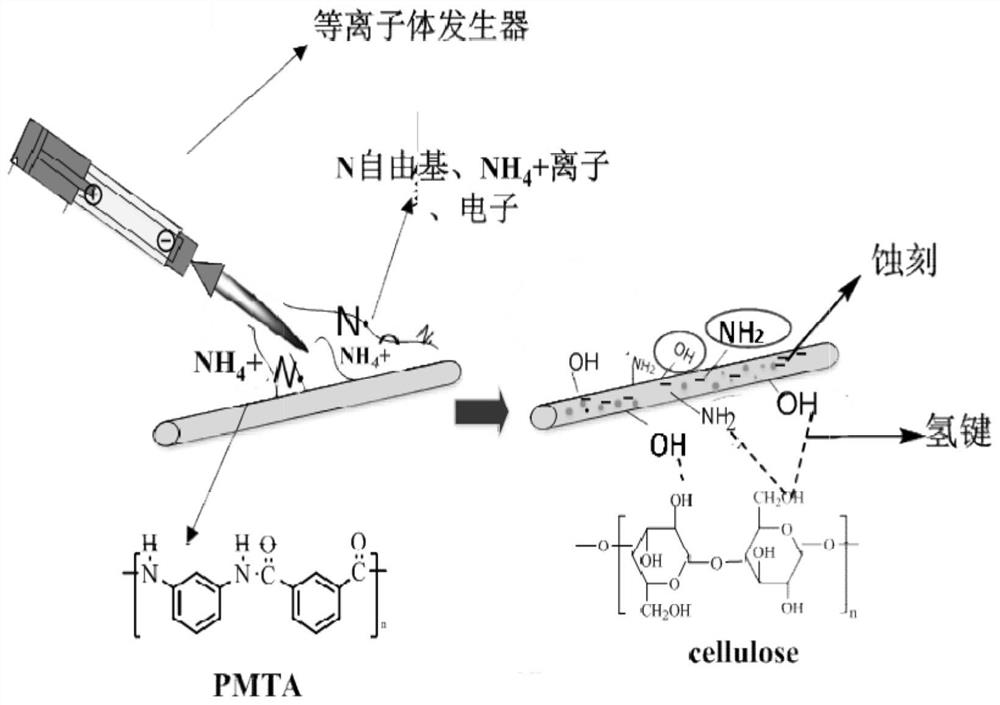

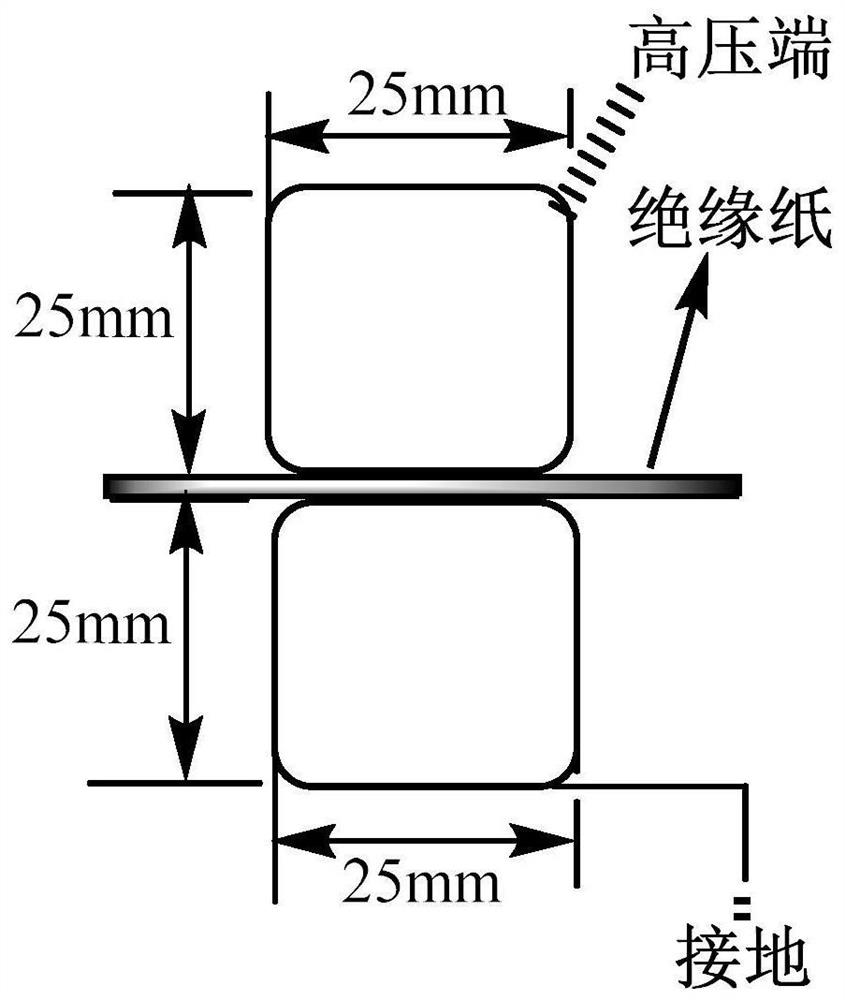

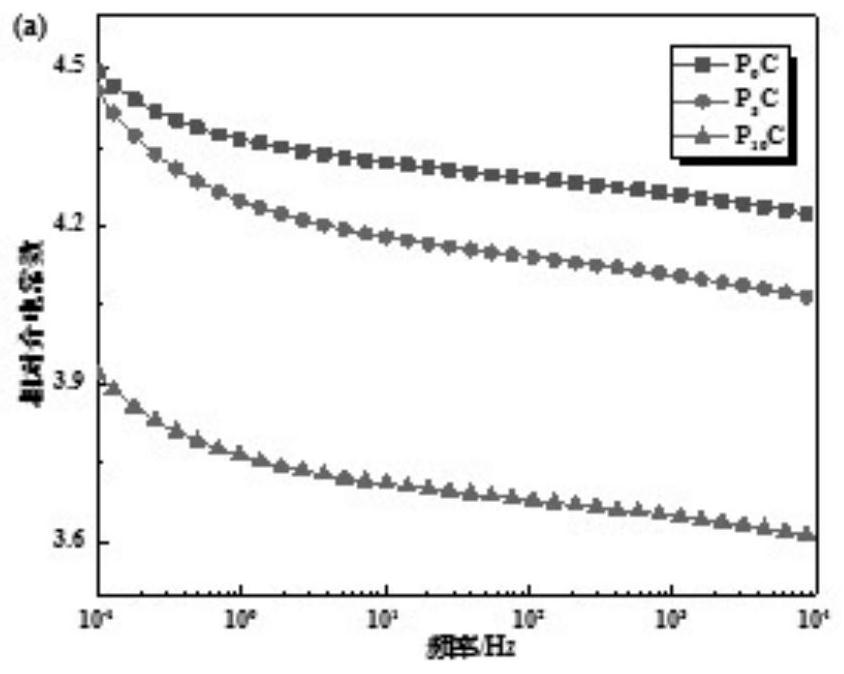

[0045] Doping different contents of aramid 1313 (PMTA) chopped fibers in natural cellulose pulp can reduce the dielectric constant and dielectric loss of insulating paper, but due to the poor bonding ability of the two fibers, the composite insulating paper sample mechanically Performance is drastically reduced. In order to make up for this defect, the present invention expounds the improvement effect of low-temperature plasma treatment on the binding ability of two kinds of cellulose, and tests and analyzes the properties of the prepared composite insulating paper. The results show that low-temperature plasma treatment can effectively improve the two kinds of cellulose The binding force between the fibers can make up for the loss of mechanical properties, but has little effect on the dielectric and breakdown properties of insulating paper. Insulating paper samples prepared by doping 10% PMTA in natural...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com