High-conductivity wool top fiber and preparation method thereof

A high-conductivity, wool-top technology, which is applied in the field of fiber products, can solve the problems of unsatisfactory conductivity of conductive wool-top fibers, poor electrical conductivity of wool-top fibers, and limited use and development, so as to enhance interface bonding ability, improve electrical conductivity, and enhance The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

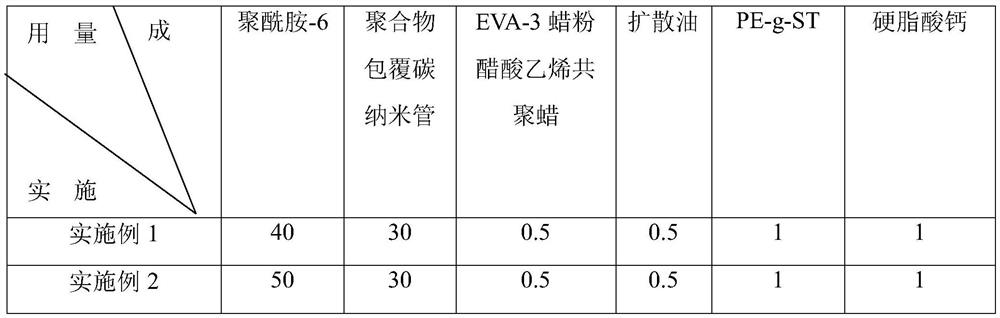

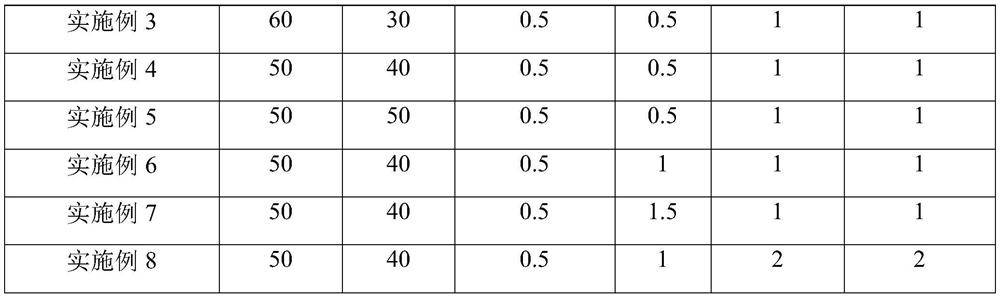

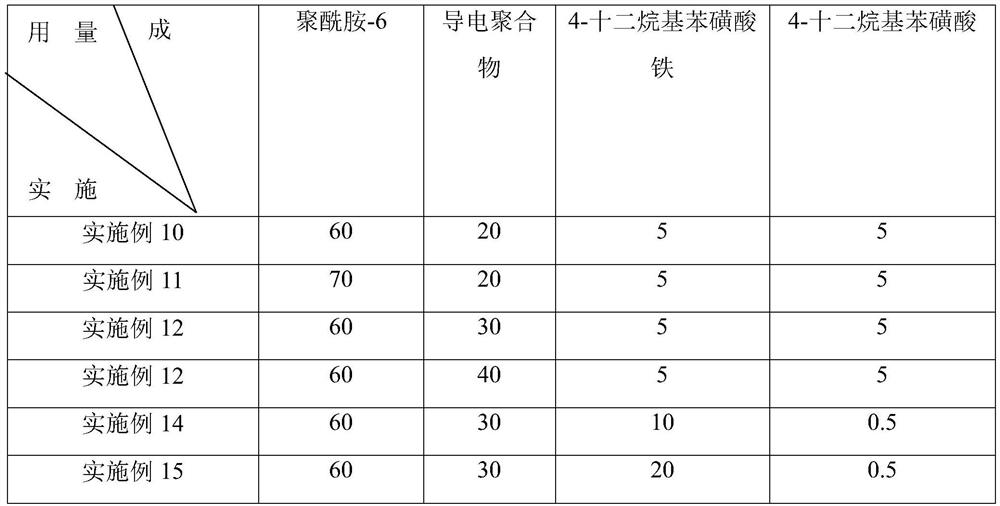

Examples

preparation example 1

[0041]The following description will be given by taking Preparation Example 1 as an example. The preparation example of the present application discloses a preparation method of polymer-coated carbon nanotubes, and the specific method is as follows:

[0042] S10, in a flask equipped with a magnetic stirring rotor, add 2g of dry carbon nanomaterials and 20mL of 60% nitric acid, ultrasonically treat with 40kHZ for 30min, heat to 120°C, stir and react under reflux for 24h, use polytetrafluoroethylene with a diameter of 0.25μm Suction filtration with vinyl fluoride microporous membrane, washed repeatedly with deionized water until neutral, and vacuum dried at 80°C for 24h to obtain 1.5g of amphiphilic carbon nanotubes;

[0043] S20, weigh 1 g of polyamide into a test tube, add 20 mL of chloroform, dissolve and add 0.05 g of amphiphilic carbon nanotubes, shake vigorously, and keep stirring for 2 hours;

[0044] S30, 20 mL of deionized water is added, vigorously shaken and ultrason...

preparation example 2

[0046] This preparation example is basically the same as that of preparation example 1, except that the polyamide in step S20 is replaced with polyaniline.

preparation example 3

[0048] This preparation example is basically the same as preparation example 1, except that the polyamide in step S20 is replaced with polyacrylonitrile.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com