Glue solution for coating television circuit board and preparation method of glue solution

A circuit board and coating technology, applied in the direction of adhesives, epoxy resin glue, adhesive types, etc., can solve the problems of easy drying and hardening, poor heat resistance, reducing the protection effect of circuit boards, etc., to achieve uniform distribution, Guaranteed protection, enhanced flexibility and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The invention provides a glue solution for coating a TV circuit board, which comprises a component A liquid and a B component liquid, and the A component liquid and the B component liquid are constituted according to a weight ratio of 10:1, and the The A component liquid includes: 48.56% epoxy resin, 5.64% curing agent, 2.15% pyrolytic graphite, 2.56% nano silicon dioxide, 41.09% organic solvent according to the weight percentage; the B component liquid Calculated by weight percentage, it includes: 56.64% polyurethane, 4.50% curing accelerator, 15.43% nanocellulose, 12.25% hexagonal boron nitride microchips, and 11.18% organic solvent;

[0029] The curing agent is dicyandiamide solution, the curing accelerator is 2-methylimidazole, and the organic solvent is N-methylpyrrolidone (NMP), ethylene glycol (EG), n-butanol, terpineol One or several compounded;

[0030] The present invention also provides a kind of preparation method of the glue solution for coating the TV cir...

Embodiment 2

[0041] The difference from Example 1 is that the A component liquid includes: 50.24% epoxy resin, 6.16% curing agent, 2.65% pyrolytic graphite, 2.74% nano silicon dioxide, 38.21% organic solvent; the B component liquid includes: 57.26% polyurethane, 5.30% curing accelerator, 17.57% nanocellulose, 12.65% hexagonal boron nitride microchips, 7.22% organic solvent .

Embodiment 3

[0043] All different from Examples 1-2, the A-component liquid includes: 49.40% epoxy resin, 5.90% curing agent, 2.40% pyrolytic graphite, 2.65% nano-silica , 39.65% organic solvent; the B component liquid includes: 56.95% polyurethane, 4.90% curing accelerator, 16.50% nanocellulose, 12.45% hexagonal boron nitride microchips, 9.20% of organic solvents.

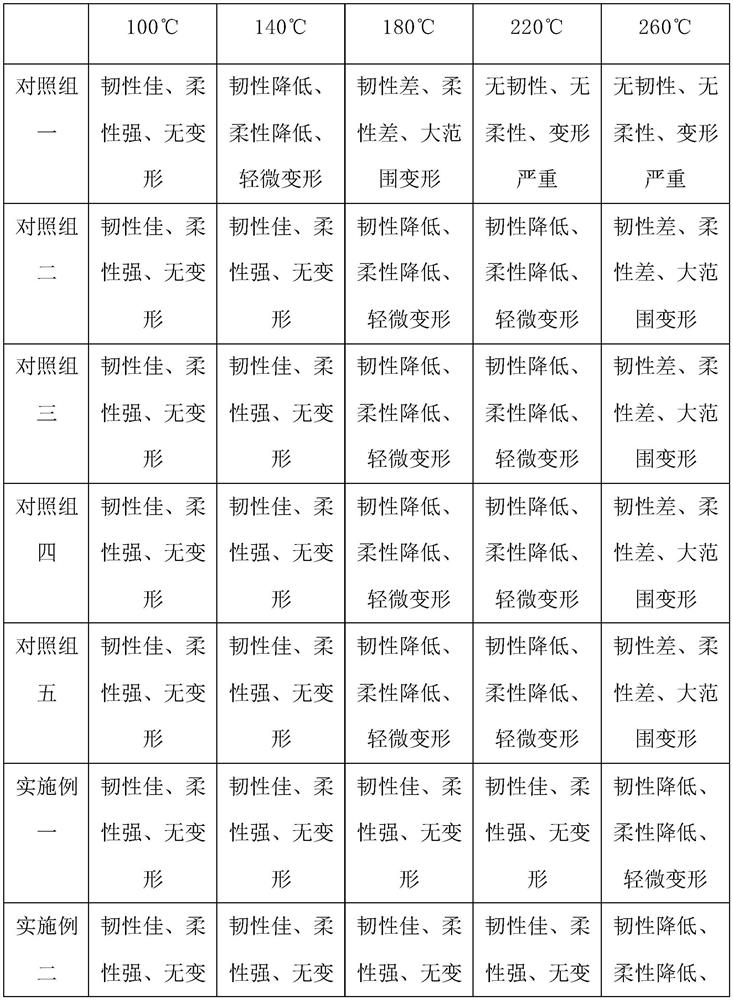

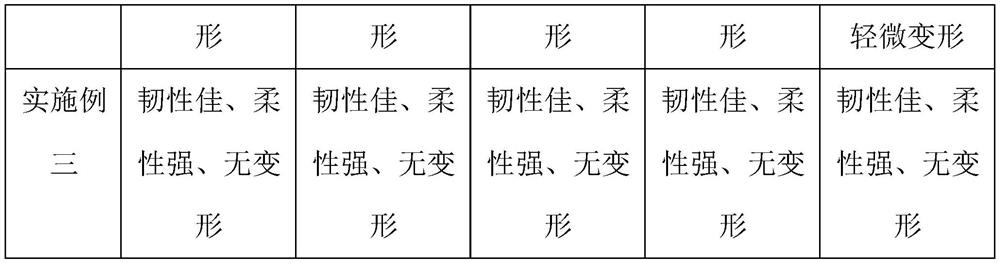

[0044] Get the TV circuit board coating glue solution that above-mentioned embodiment 1-3 makes and the circuit board coating glue solution of control group one, the circuit board coating glue solution of control group two, the circuit board coating solution of control group three The glue solution for coating the board, the glue solution for the circuit board coating of the control group 4 and the glue solution for the circuit board coating of the control group 5, the glue solution for the circuit board coating of the control group 1 is an ordinary circuit board on the market Glue for coating, the glue for coating the circui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com