Wall surface structure based on hidden screw connection mode

A screw connection and concealed technology, which is applied to building components, building structures, buildings, etc., can solve the problems of inconvenient installation and poor waterproof performance, and achieve the effects of quick and convenient installation, corrosion prevention, and good cost-effective advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

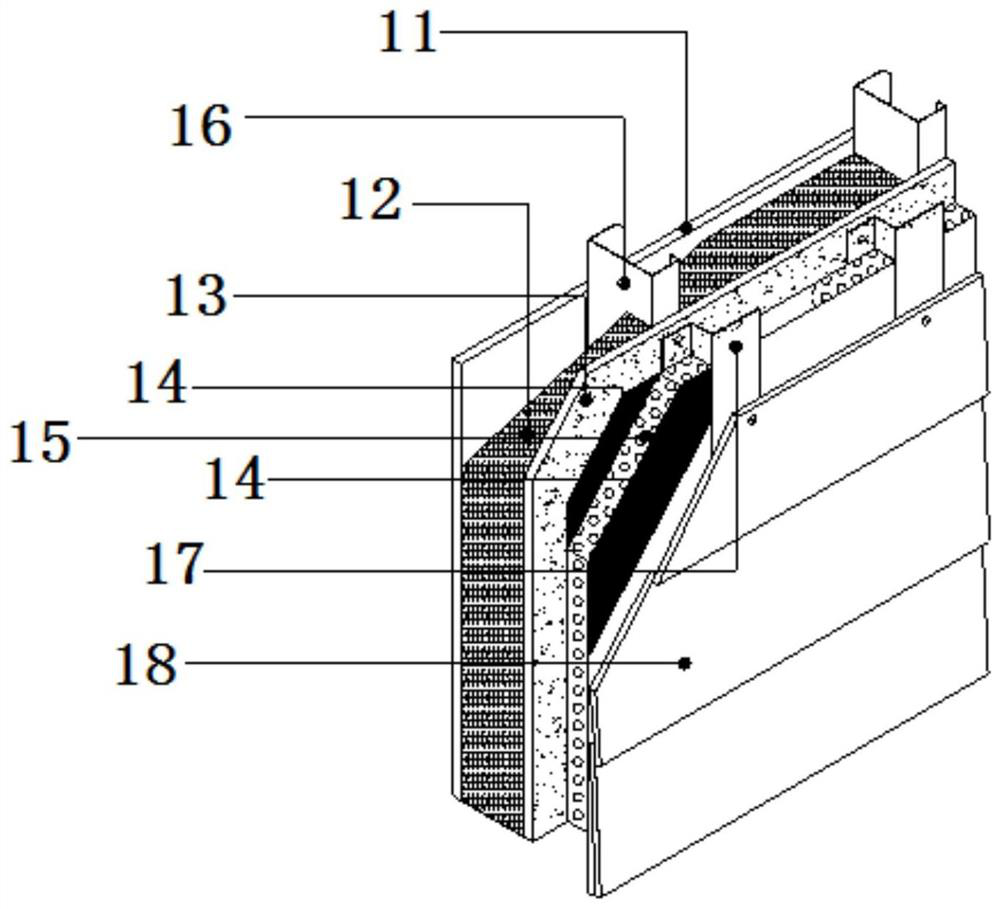

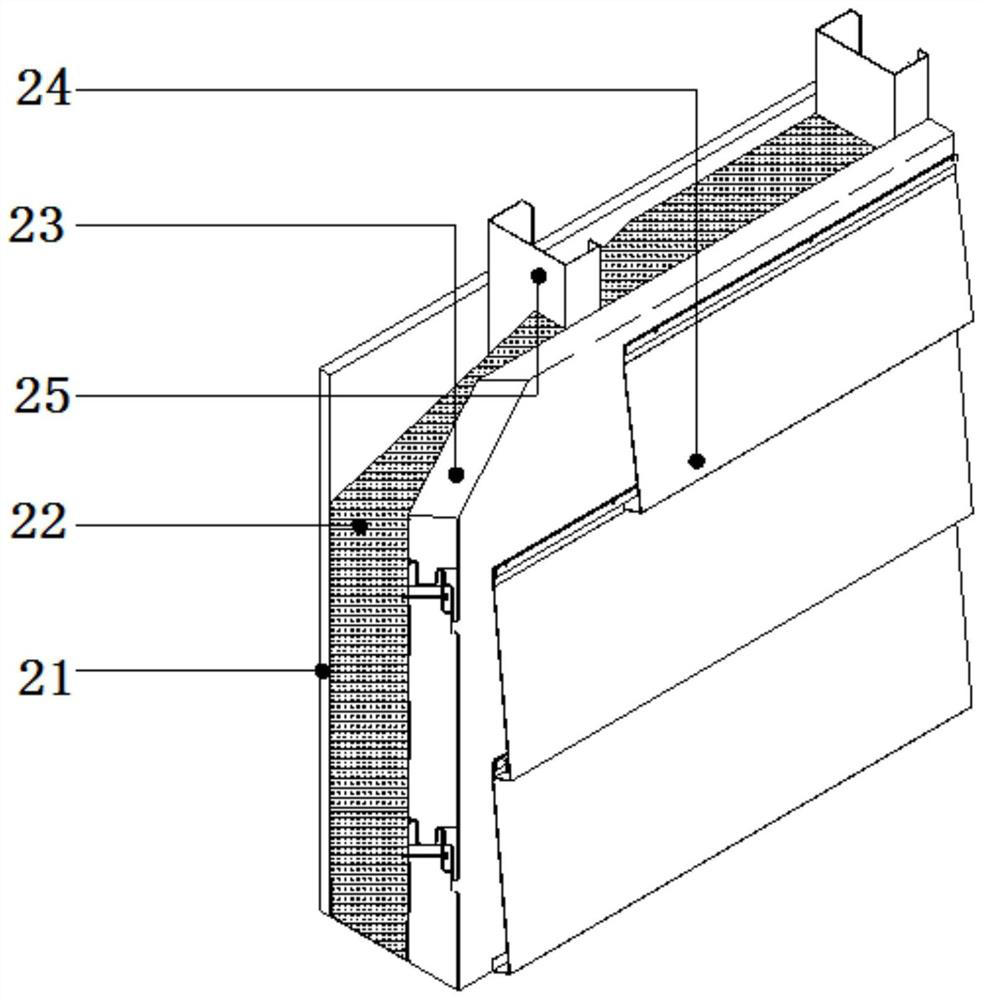

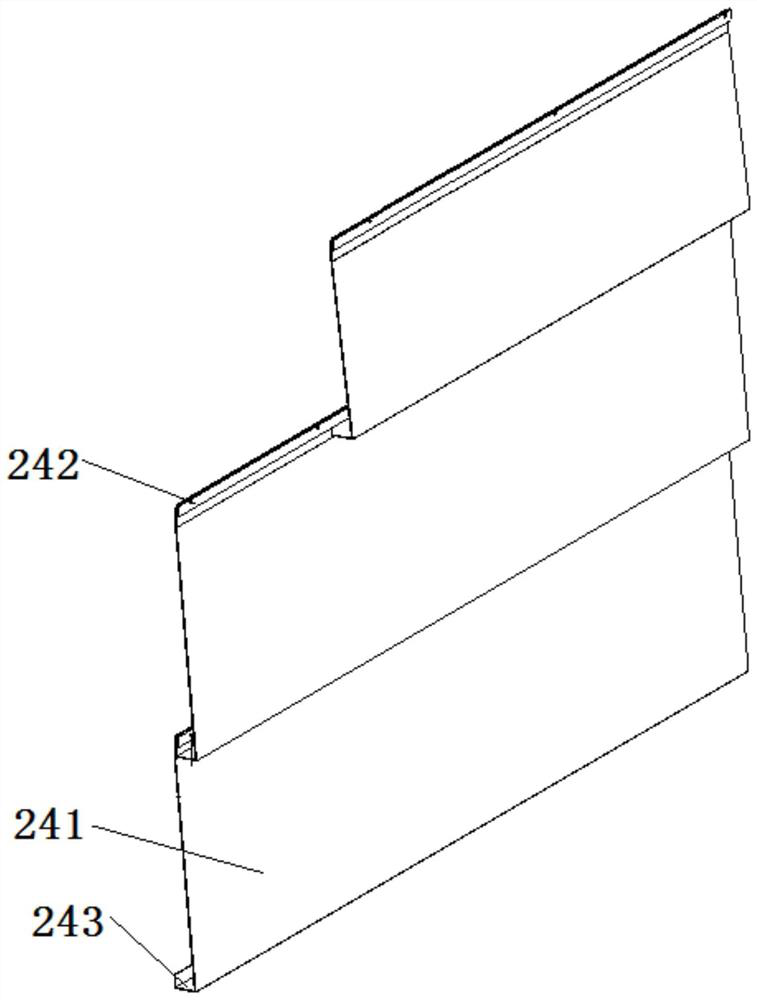

Embodiment 1

[0026] refer to figure 2 , image 3 , a wall structure based on a hidden screw connection method, including gypsum board 21, glass fiber cotton 22, polyurethane sandwich composite board 23, stepped board 24 and cold-formed thin-walled steel column 25, the gypsum board 21 and polyurethane sandwich The composite boards 23 are arranged in parallel at intervals, the cold-formed thin-walled steel columns 25 are arranged between the gypsum board 21 and the polyurethane sandwich composite board 23, and the cold-formed thin-walled steel columns 25 are respectively connected with the gypsum board 21 and the polyurethane sandwich The composite board 23 is connected, the glass fiber cotton 22 is filled between the gypsum board 21 and the polyurethane sandwich composite board 23, and the said stepped board 24 is provided with several pieces. The outer side of the board 23, and the stepped board 24 and the polyurethane sandwich composite board 23 are also connected by screws, and the scr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com