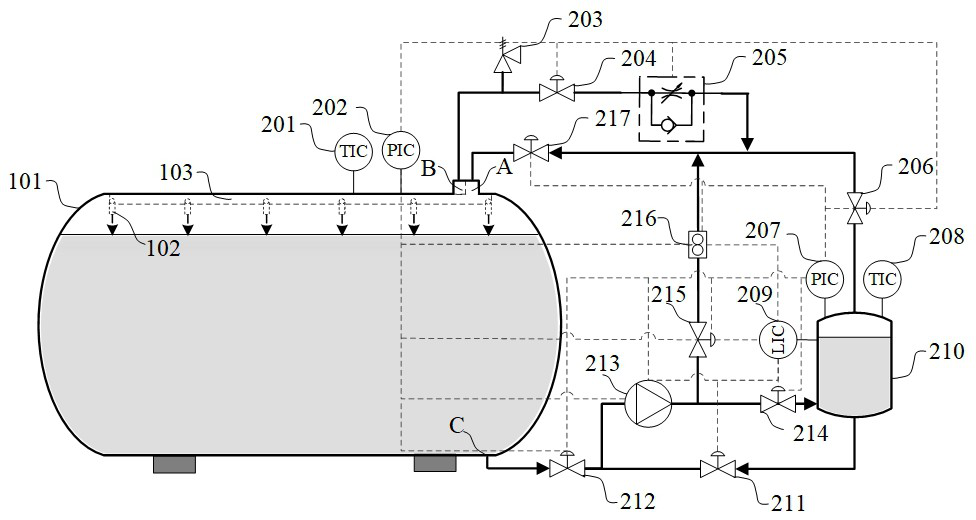

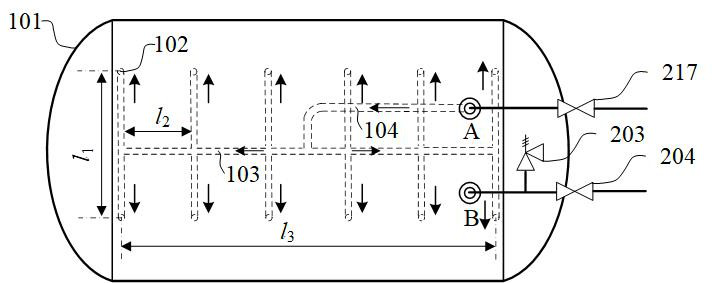

Long-distance liquid helium transportation and storage tank pressure regulation and control device

A long-distance, storage tank technology, applied in non-pressure vessels, installation devices for container structures, gas/liquid distribution and storage, etc., can solve problems such as large input power consumption, complex refrigeration equipment, increased transportation costs and maintenance requirements , to achieve the effects of slowing down evaporation, ensuring safety, and weakening the effect of thermal stratification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0026] Step 1: Open the storage tank draining ball valve 212, cryopump 213, liquid helium pipeline ball valve 215, flow meter 216, and reinjection ball valve 217 in sequence; when the first temperature controller 201 or the first pressure controller 202 monitors the When the temperature and pressure in the upper space of the tank no longer drop, close the above equipment;

[0027] Step 2: When the first pressure controller 202 monitors that the storage tank pressure rises to a safe value P 0 When the 95% of the storage tank discharge ball valve 212, the cryopump 213, and the Dewar tank liquid injection ball valve 214 are opened in turn, the helium liquid is slowly injected into the Dewar tank 210 from the storage tank; when the second pressure controller 207 monitors the Dewar tank When the tank pressure rises to 0.1MPa, close the Dewar tank liquid injection ball valve 214, cryopump 213, and storage tank drain ball valve 212 in sequence;

[0028] Step 3: Open the storage tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com