Active clamping push-pull buck-boost DC converter

A technology of DC converter and composite active clamp, which is applied in the direction of converting DC power input to DC power output, instruments, and adjusting electric variables, etc. It can solve the power circuit spurs, it is difficult to realize wide-range input and output changes, and the system is stable To avoid the adverse effects of sex and other problems, achieve the effect of low switch voltage stress, wide range of input voltage variation, and electrical isolation between output and input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

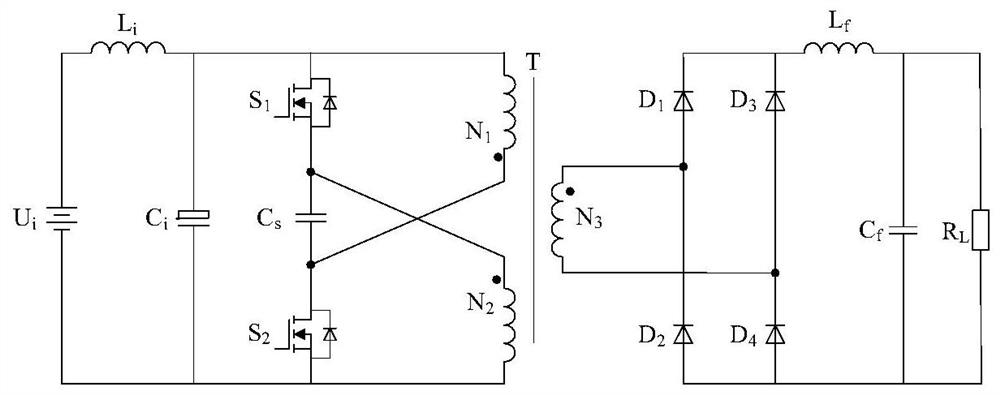

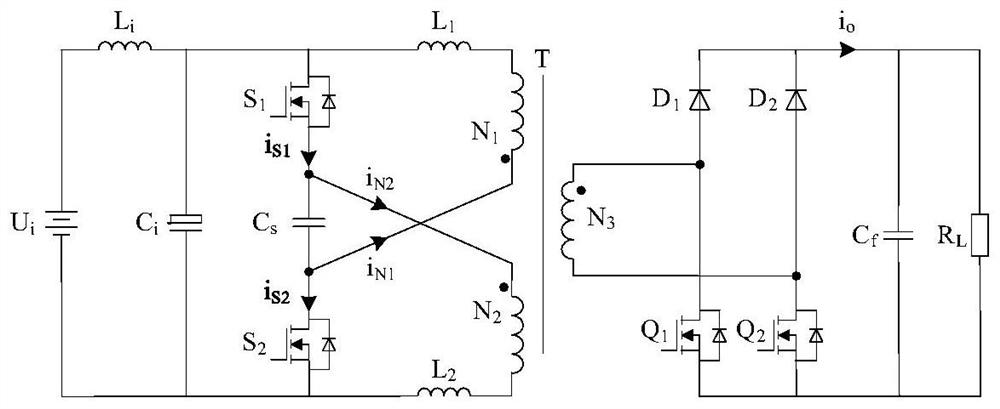

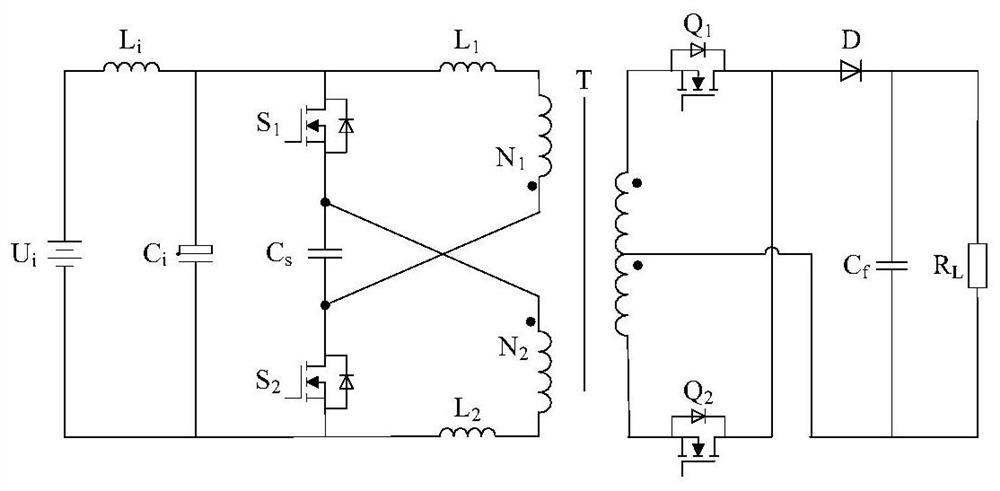

[0018] Bonded below figure 2 The first embodiment shown and Figure 4-6 The working principle of the active clamps proposed by the present invention is described as an example of working in the CRM mode. However, the invention is not limited to these examples. The present invention encompasses any alternative, modifications, equivalents, and programs made in the spirit and scope of the invention. Some specific details of the present invention will be detailed below. The description of these detail portions can also be fully understood in the art. At the same time, in order to more reflect the characteristics of the present invention, well-known methods, processes, processes, and elements are not described in detail.

[0019] figure 2 A structural diagram of the first embodiment of the active clamp push-pull elevator DC converter proposed by the present invention, figure 2 The positive direction of each current is also specified.

[0020] Figure 4 The first embodiment of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com