Oxygen-argon separator

A separator, oxygen and argon technology, applied in the field of chromatographic separation, can solve problems such as the inability to realize the separation of oxygen and argon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

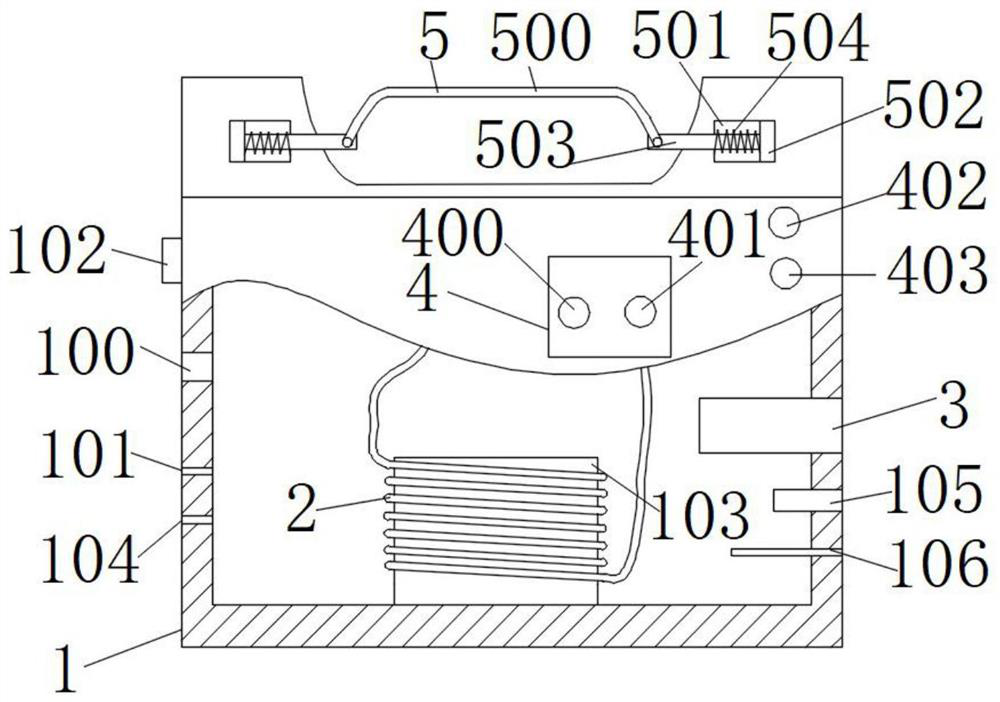

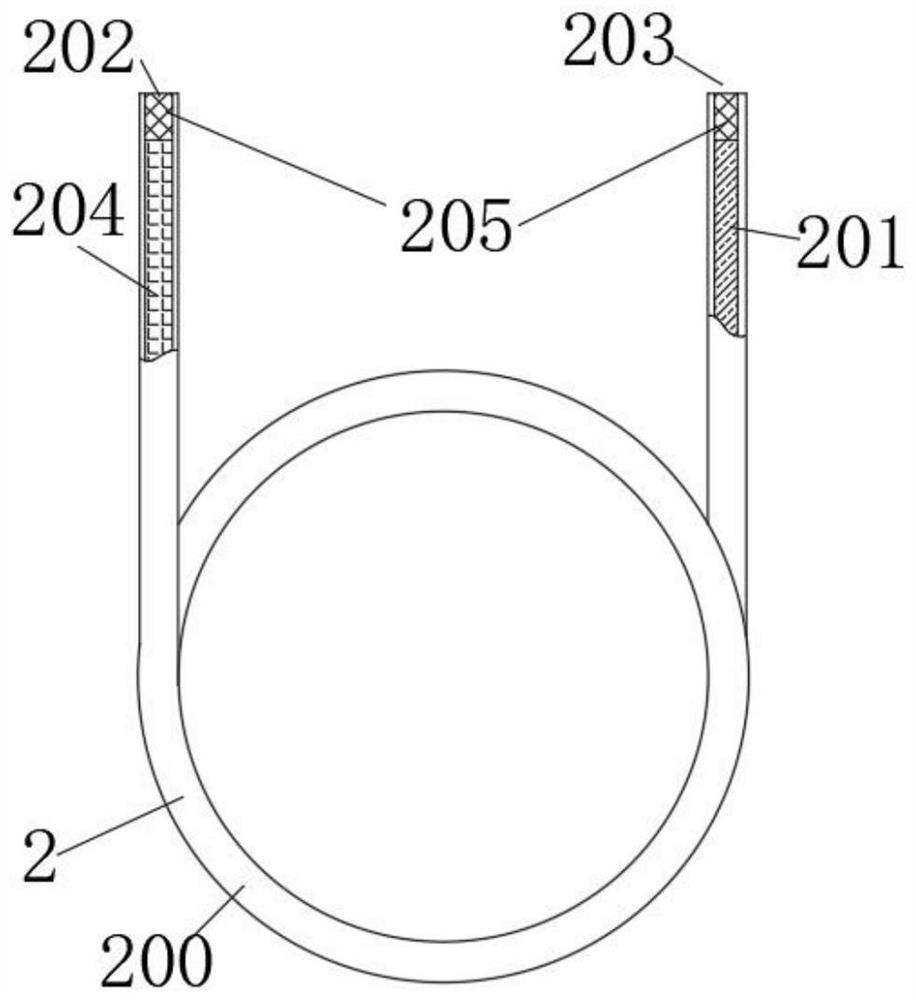

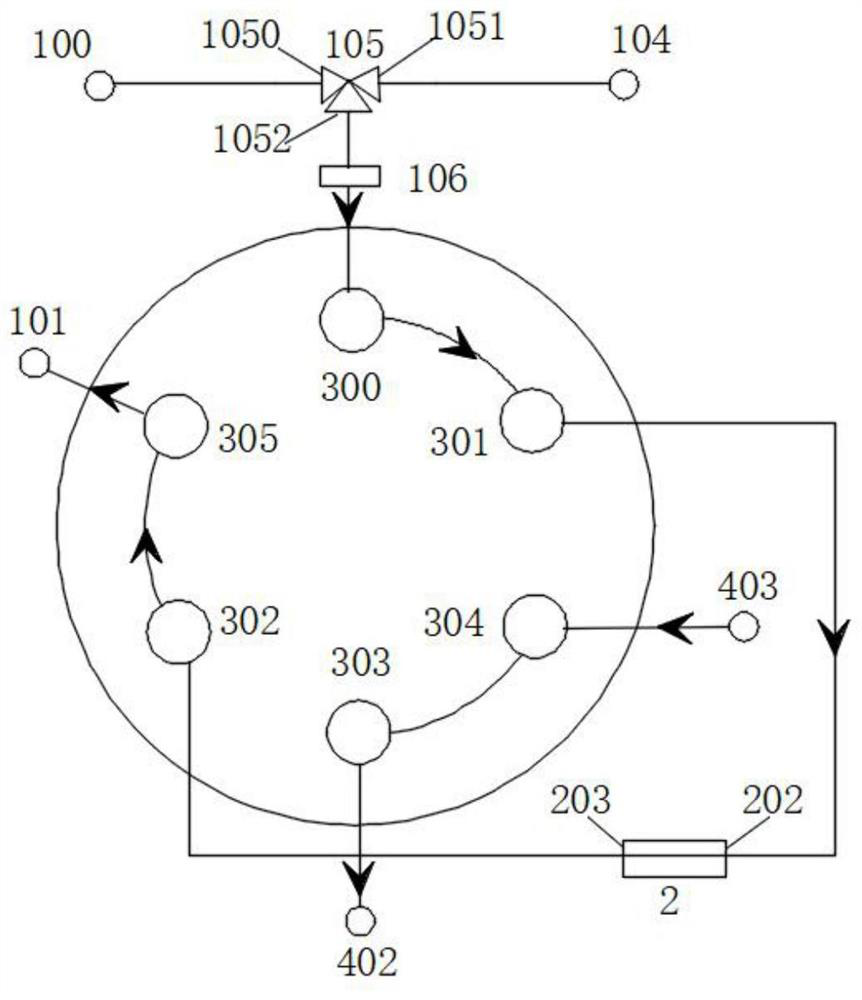

[0055] The embodiment of the present invention provides an oxygen-argon separator, such as Figure 1-4 As shown, it includes a separator body 1 and a body upper cover, the separator body 1 is a hollow structure, and the separator body 1 is provided with an oxygen-argon separation column 2 (the oxygen-argon separation column 2 is provided with a selective adsorption molecular sieve) and a heating device, the oxygen-argon separation column 2 is sleeved on the heating device, and the separator body 1 is provided with a sample injector 3, a reducing gas inlet 100 and an outlet 101;

[0056] The reducing gas inlet 100 communicates with one end of the oxygen-argon separation column 2 through one port of the sampler 3 , and the other end of the oxygen-argon separation column 2 communicates with the other port of the sampler 3 . The discharge ports 101 communicate with each other to form a reducing gas path.

[0057] The beneficial effects of the above technical solutions are: the de...

Embodiment 2

[0060] On the basis of the above Example 1, as Figure 1-4 As shown, a chromatograph 4 is provided on the outside of the separator body 1. The chromatograph 4 is provided with a chromatographic air inlet 400 and a chromatographic air outlet 401. The separator body 1 is provided with a chromatographic output port 402 and a chromatographic input port. port 403, the chromatographic air inlet 400 is connected to the chromatographic output port 402, and the chromatographic air outlet 401 is connected to the chromatographic input port 403;

[0061] The separator body 1 is provided with a power switch 102, the heating device is a heating column 103, the oxygen-argon separation column 2 is sleeved on the heating column 103, the power switch 102 and the heating device 103 electrical connection;

[0062] The separator body 1 is provided with a carrier gas port 104 and a switch device. The switch device includes a three-way switch 105 and a needle valve 106. The three-way switch 105 inc...

Embodiment 3

[0071] On the basis of Embodiment 1 or 2, a carrying handle 5 is provided on the upper cover of the main body, and the carrying handle 5 includes a handle body 500 and two symmetrically arranged buffer adjustment devices, and the buffer adjustment device includes a sliding plug groove 501 , a sliding plug 502, a sliding plug rod 503 and a buffer spring 504, the sliding plug groove 501 is set in the upper cover of the body, the sliding plug 502 is slidably connected in the sliding plug groove 501, and the sliding plug rod 503 is coaxially arranged in the sliding plug groove 501, one end of the sliding plug rod 503 is fixedly connected with the sliding plug 502, the other end of the sliding plug rod 503 is hingedly connected with the handle body 500, the buffer The spring 504 is disposed in the sliding plug groove 501 and sleeved on the sliding plug rod 503 .

[0072] The beneficial effects of the above technical solutions are: the design of the carrying handle 5 facilitates the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com