Chip type structure catalysis multiphase microreactor

A micro-reactor, catalytic reaction technology, applied in chemical/physical/physical-chemical reactors, chemical instruments and methods, chemical/physical processes, etc., to achieve uniform distribution, optimize gas-liquid mass transfer, and reduce pressure drop.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

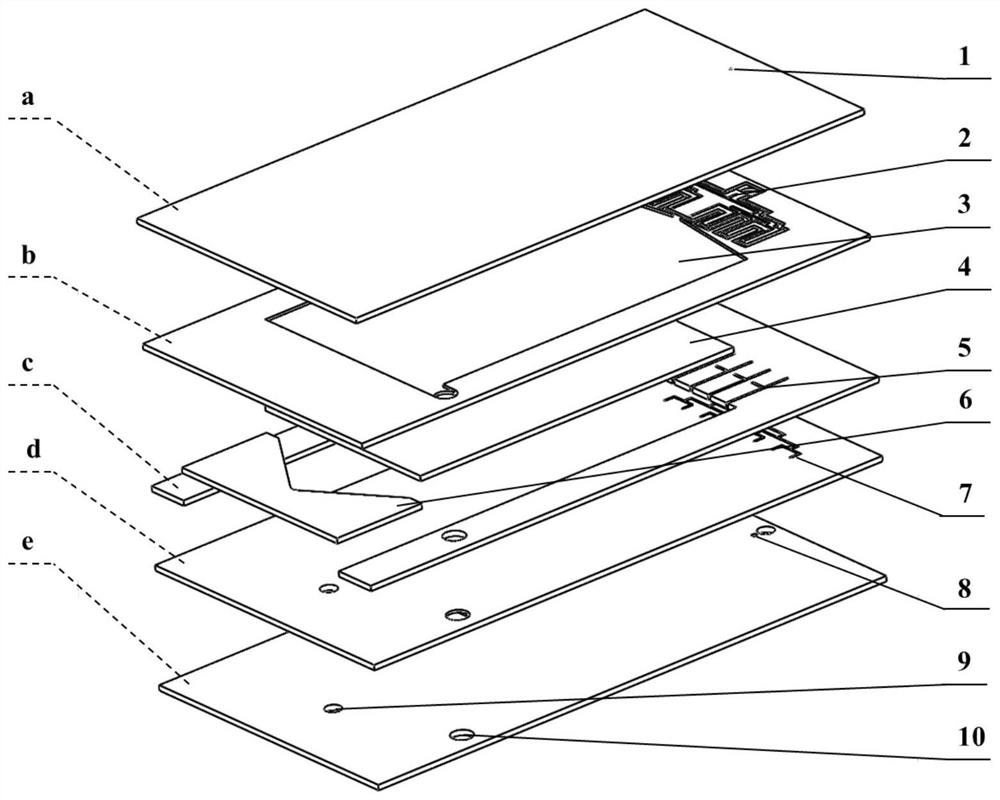

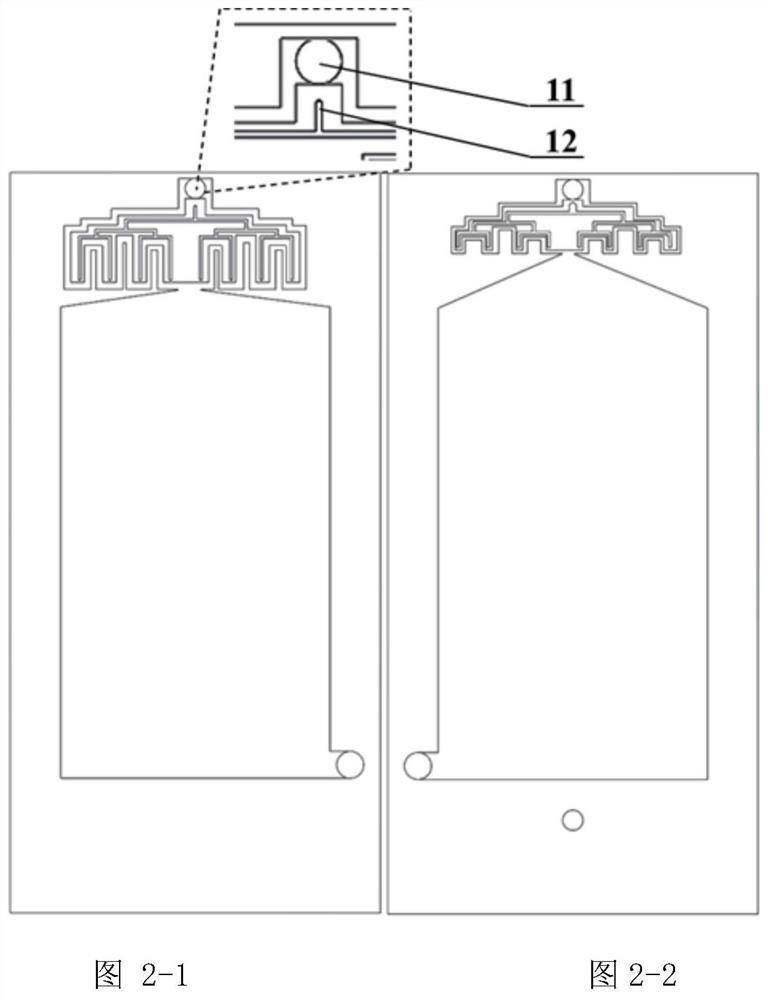

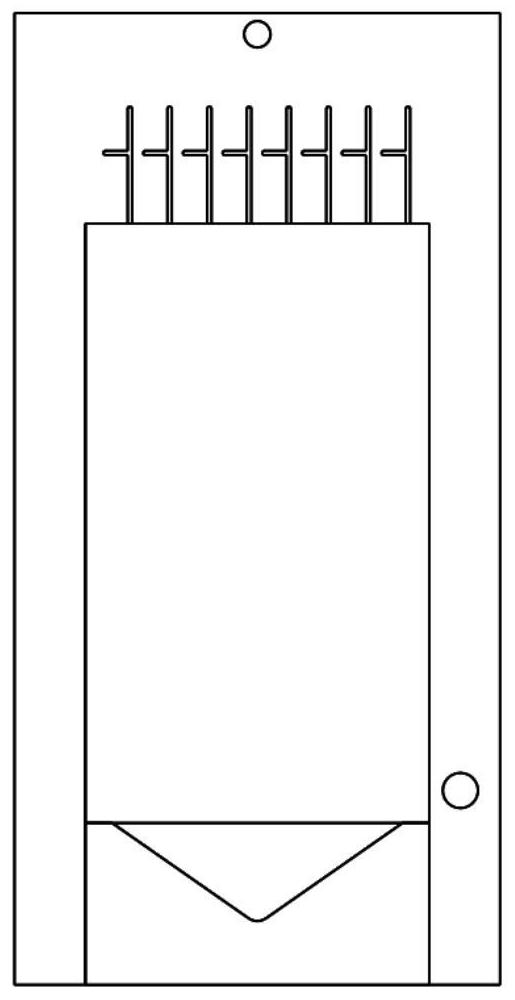

[0041] see figure 1 , a catalytic multiphase microreactor with a chip structure, consisting of an upper cover plate a, a first heat transfer distribution mixing reaction integration plate b, a shear mixing and catalytic reaction chamber plate c, and a second heat transfer distribution mixing reaction integration plate d , the lower cover e, composed of several parts.

[0042]It is characterized in that: the upper cover plate a includes the gas / liquid inlet 1; the first heat exchange distribution mixed reaction integrated plate b, the plate is respectively distributed with the reactant distribution flow channel 2 and the heat exchange channels on both sides of the distribution flow channel and The heat exchange surface 3 in the multiphase reaction area; the structural catalyst 4; the multiphase reaction chamber plate c, its two parts gas-liquid shear mixing channel 5; the rear end is sealed with a sealing plate 6; the second heat exchange distribution mixing reaction integrated...

Embodiment 2

[0048] see figure 1 , a catalytic multiphase microreactor with a chip structure, consisting of an upper cover plate a, a first heat transfer distribution mixing reaction integration plate b, a shear mixing and catalytic reaction chamber plate c, and a second heat transfer distribution mixing reaction integration plate d , the lower cover e, composed of several parts.

[0049] It is characterized in that: the upper cover plate a includes the gas / liquid inlet 1; the first heat exchange distribution mixed reaction integrated plate b, the plate is respectively distributed with the reactant distribution flow channel 2 and the heat exchange channels on both sides of the distribution flow channel and The heat exchange surface 3 in the multiphase reaction area; the structural catalyst 4; the multiphase reaction chamber plate c, its two parts gas-liquid shear mixing channel 5; the rear end is sealed with a sealing plate 6; the second heat exchange distribution mixing reaction integrate...

Embodiment 3

[0056] see figure 1 , a catalytic multiphase microreactor with a chip structure, consisting of an upper cover plate a, a first heat transfer distribution mixing reaction integration plate b, a shear mixing and catalytic reaction chamber plate c, and a second heat transfer distribution mixing reaction integration plate d , the lower cover e, composed of several parts.

[0057] It is characterized in that: the upper cover plate a includes the gas / liquid inlet 1; the first heat exchange distribution mixed reaction integrated plate b, the plate is respectively distributed with the reactant distribution flow channel 2 and the heat exchange channels on both sides of the distribution flow channel and The heat exchange surface 3 in the multiphase reaction area; the structural catalyst 4; the multiphase reaction chamber plate c, its two parts gas-liquid shear mixing channel 5; the rear end is sealed with a sealing plate 6; the second heat exchange distribution mixing reaction integrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com