Recycling method for generating carbon source by hydrolysis acidification of sludge of sewage plant

A technology for sludge hydrolysis and acidification, sewage treatment plant, applied in chemical instruments and methods, sludge treatment, biological sludge treatment, etc. Market Application Prospects, Optimizing Operating Costs, and the Effects of Optimizing Operating Conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

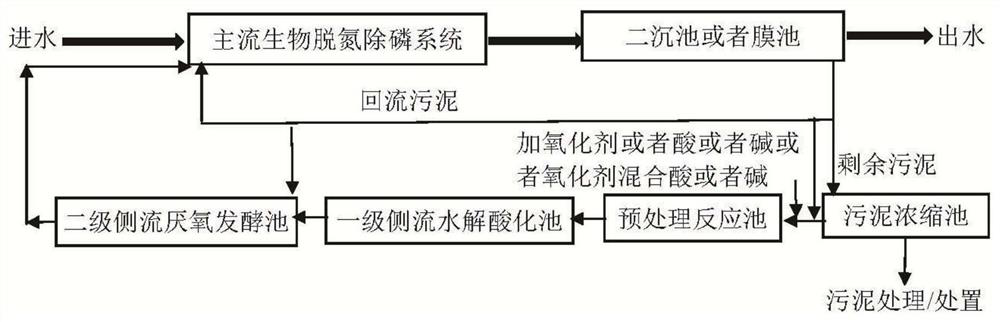

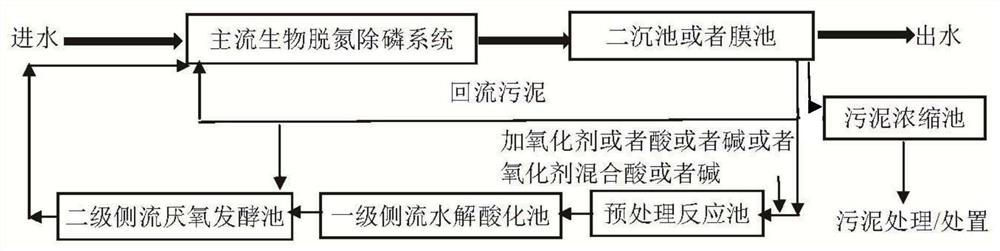

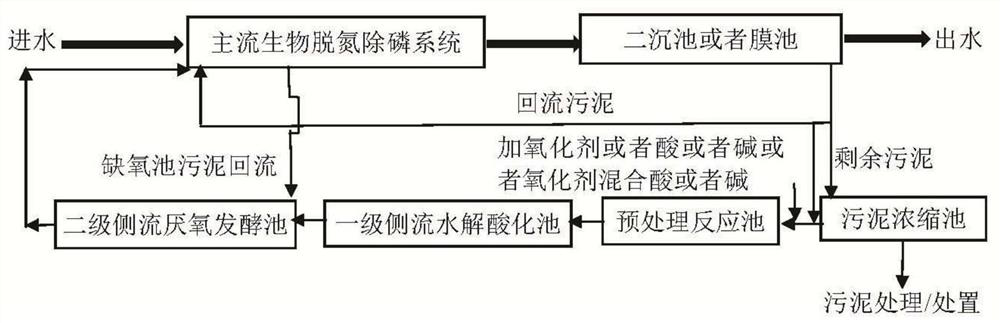

Method used

Image

Examples

Embodiment 1

[0048] The concentration of the sludge in the secondary settling tank of the municipal sewage plant is 1.1%. Add 500 mg / L sodium hypochlorite to the sludge and mix it for 4 hours, then add it to the hydrolytic acidification tank equivalent to the side stream primary sludge hydrolysis acidification process section. The hydrolysis acidification tank keeps Run in continuous run CSTR mode with a 16 hour residence time at room temperature. The soluble COD SCOD of the sludge after pretreatment and primary side-stream hydrolysis and acidification increased from 38mg / L to 655mg / L. Then add 100 milliliters of sludge through side flow sludge pretreatment and primary side flow hydrolysis and acidification treatment in 1 liter equivalent to secondary side flow anaerobic fermentation tank, which is equivalent to 10% Q secondary sedimentation tank return sludge After the side stream pretreatment, add the first-stage side stream hydrolysis and acidification of the sludge, add 100 ml of secon...

Embodiment 2

[0050] The concentration of the sludge in the secondary settling tank of the municipal sewage plant is 2.7%. Add 500mg / L sodium hypochlorite to the sludge and mix it for 4 hours before adding it to the hydrolytic acidification tank equivalent to the first-level side flow hydrolysis acidification process section of the side flow sludge. The hydrolytic acidification cell was maintained at room temperature for a 16-hour residence time and operated in a continuously operating CSTR mode. The soluble COD SCOD of the sludge after pretreatment and primary side-stream hydrolysis and acidification increased from 28mg / L to 839mg / L. Then add 100 milliliters of sludge through side flow sludge pretreatment and primary side flow hydrolysis and acidification treatment in 1 liter equivalent to secondary side flow anaerobic fermentation tank, which is equivalent to 10% Q secondary sedimentation tank return sludge Add 200 ml of anoxic pool sludge with a concentration of 0.5% after side stream pr...

Embodiment 3

[0052] The concentration of the sludge in the membrane tank of the industrial sewage plant is 1.2%. Add 400mg / L30% sodium hydroxide to the sludge and mix it for 2 hours before adding it to the hydrolytic acidification tank which is equivalent to the side-stream sludge primary side-stream hydrolysis acidification process section. The primary hydrolytic acidification tank is maintained at 35°C for an 18-hour residence time and operated as a CSTR mode of continuous operation. After pretreatment and primary hydrolysis and acidification, the soluble COD SCOD of the sludge increased from 24mg / L to 582mg / L. Then add 120 milliliters of sludge through side flow pretreatment and first-level side flow hydrolysis acidification in 1 liter of equivalent side flow secondary side flow anaerobic fermentation tank, the membrane pool return sludge that is equivalent to 12% Q passes through Add 250 ml of anoxic pool sludge with a concentration of 0.55% after side stream pretreatment and side stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com