Method for preparing artificial decorative stone by using manganese-silicon alloy hot melting slag

A manganese-silicon alloy and hot-melting slag technology is applied in the field of preparing artificial decorative stone by using manganese-silicon alloy hot-melting slag. Avoid environmental pollution, good energy saving and environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

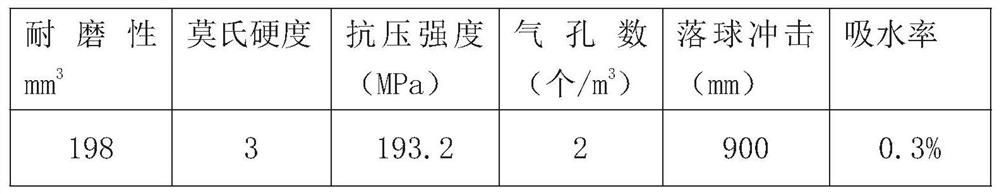

Embodiment 1

[0023] A method for preparing artificial decorative stones by manganese-silicon alloy hot slag, comprising the following steps:

[0024] S1. Synchronously add manganese-silicon alloy hot slag and clarifying agent into the quenched and tempered electrolytic furnace according to the required mass percentage to obtain mixed slag, keep the temperature in the quenched and tempered electrolytic furnace at 1100-1200°C, and heat evenly for 2 hours;

[0025] S2. After the homogeneous heating is completed, pour the mixed slag into the pre-prepared mold through the slag outlet of the quenched and tempered electrolytic furnace, and then quickly transfer the mold to the crystallization furnace to control the temperature of the crystallization furnace At 800°C-1000°C, keep warm for 2 hours to obtain crystals;

[0026] S3. After the heat preservation is completed, stop the heating of the crystallization furnace, and after the temperature of the crystallization furnace is naturally cooled to ...

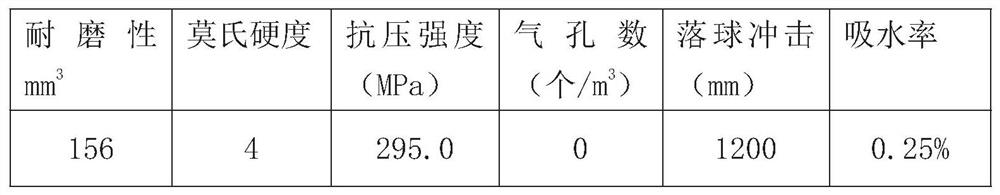

Embodiment 2

[0036] This example is another embodiment of Example 1. The difference between this example and Example 1 lies in the process parameters in the process of preparing artificial decorative stones, the addition mass percentages of manganese-silicon alloy hot slag and clarifier, and the following only Portions different from those in Embodiment 1 will be described.

[0037] A method for preparing artificial decorative stones by manganese-silicon alloy hot slag, comprising the following steps:

[0038] S1. Synchronously add manganese-silicon alloy hot slag and clarifying agent into the quenched and tempered electrolytic furnace according to the required mass percentage to obtain mixed slag, keep the temperature in the quenched and tempered electrolytic furnace at 1200-1300°C, and heat evenly for 2 hours;

[0039] S2. After the homogeneous heating is completed, pour the mixed slag into the pre-prepared mold through the slag outlet of the quenched and tempered electrolytic furnace, a...

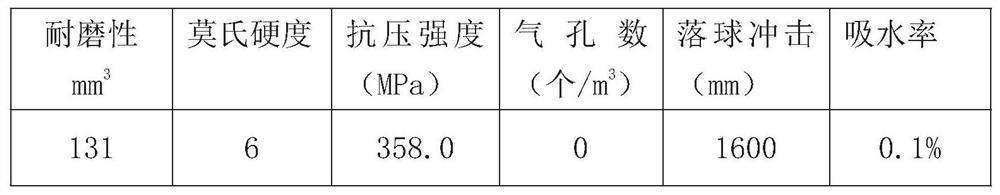

Embodiment 3

[0046] This example is another embodiment of Example 1. The difference between this example and Example 1 lies in the process parameters in the process of preparing artificial decorative stones, the addition mass percentage of manganese-silicon alloy hot slag and clarifier, and the following only Portions different from those in Embodiment 1 will be described.

[0047] A method for preparing artificial decorative stones by manganese-silicon alloy hot slag, comprising the following steps:

[0048] S1. Synchronously add manganese-silicon alloy hot slag and clarifying agent into the quenched and tempered electrolytic furnace according to the required mass percentage to obtain mixed slag, keep the temperature in the quenched and tempered electrolytic furnace at 1300-1400 ° C, and heat for 2 hours;

[0049] S2. After homogeneous mixing and heating, pour the mixed slag into the pre-prepared mold through the slag outlet of the quenched and tempered electrolytic furnace, and then quic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com