Method for removing iron in waste ternary lithium battery recovery process

A ternary lithium battery, waste technology, used in battery recycling, waste collector recycling, recycling technology and other directions, can solve the problems of difficult filtration of sediments, secondary pollution, etc., to achieve good filtration performance and increase added value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Add excess iron powder to the pickling solution of waste ternary lithium battery positive electrode / cell powder, stir at 55°C for 0.5h, and filter to obtain the pickling solution after copper removal (see Table 1).

[0026] 2. Heating in a water bath and controlling the temperature at 30°C. During the stirring process, the flocculant polyacrylamide was added to the acid dipping solution of the waste ternary lithium battery after copper removal according to 0.5% of the mass of the iron element, and then a certain concentration of ammonia water was added to adjust the pH to 1, and stirred for 2 hours.

[0027] 3. Raise the temperature of the water bath to 40°C, ventilate air at a ventilation rate of 6 L / min, add a certain concentration of ammonia water to adjust the pH to 3, and stir for 3 hours.

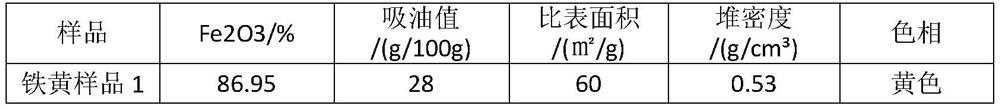

[0028] 4. Filtrate, wash the precipitate, and obtain the iron yellow product (see Table 2) after drying.

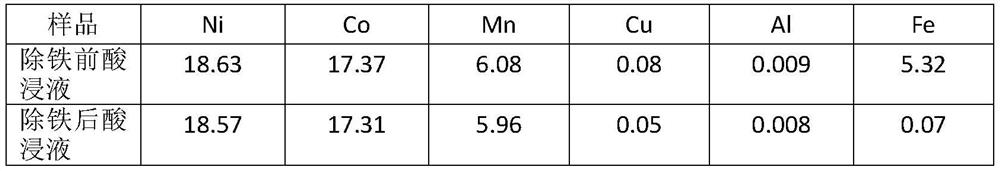

[0029] Table 1. Solution composition list after iron removal (uni...

Embodiment 2

[0034] 1. Add excess iron powder to the pickling solution of the waste ternary lithium battery positive electrode / cell powder, stir at 55°C for 0.5h, and filter to obtain the pickling solution after copper removal (see Table 3).

[0035] 2. Heating in a water bath and controlling the temperature at 35°C. During the stirring process, the flocculant polyethyleneimine was added to the acid dipping solution of the waste ternary lithium battery after copper removal according to 1.7% of the mass of the iron element, and then a certain concentration of ammonia water was added to adjust the pH to 1.7, and stirred for 1 hour.

[0036] 3. Raise the temperature of the water bath to 55°C, feed air at a ventilation rate of 4 L / min, add a certain concentration of ammonia water to adjust the pH to 4, and stir for 2 hours (see Table 4).

[0037] 4. Filtrate, wash the precipitate, and dry to obtain the iron yellow product.

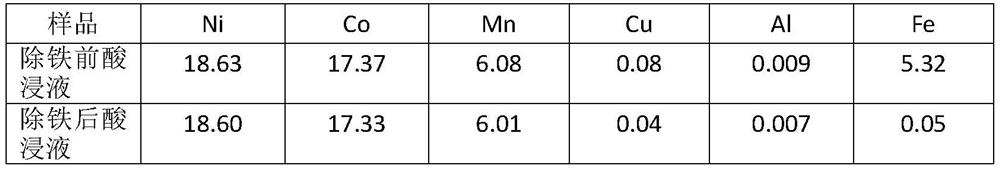

[0038] Table 3. Solution composition list after iron removal (unit: ...

Embodiment 3

[0043] 1. Add excess iron powder to the pickling solution of the waste ternary lithium battery positive electrode / cell powder, stir at 55°C for 0.5h, and filter to obtain the pickling solution after copper removal (see Table 5).

[0044] 2. Heating in a water bath and controlling the temperature at 40°C. During the stirring process, the flocculant polyethyleneimine was added to the acid dipping solution of the waste ternary lithium battery after copper removal according to 1% of the mass of the iron element, and then a certain concentration of ammonia water was added to adjust the pH to 2.5, and stirred for 0.5h.

[0045] 3. Raise the temperature of the water bath to 70°C, ventilate air at a ventilation rate of 2L / min, add a certain concentration of ammonia water to adjust the pH to 5, and stir for 1 hour.

[0046] 4. Filter, wash the precipitate, and obtain the iron yellow product (see Table 6) after drying.

[0047] Table 5. Solution composition list after iron removal (uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com