Film layer and forming method thereof

A technology of film layer and diamond-like film, which is applied in the field of film layer and its formation, can solve the problems of high internal stress of diamond-like film layer and low hardness of diamond-like film layer, and achieve the effect of improving hardness and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

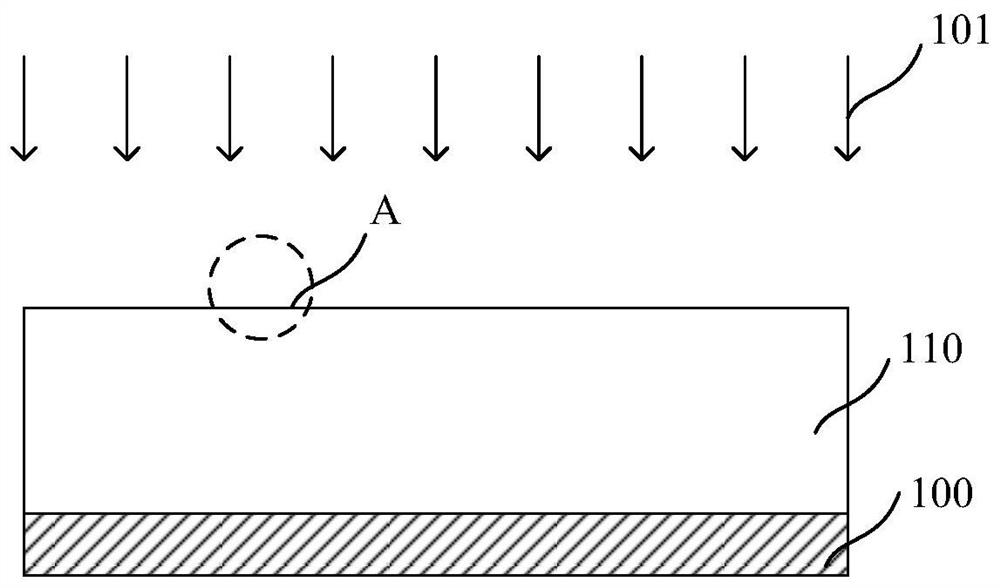

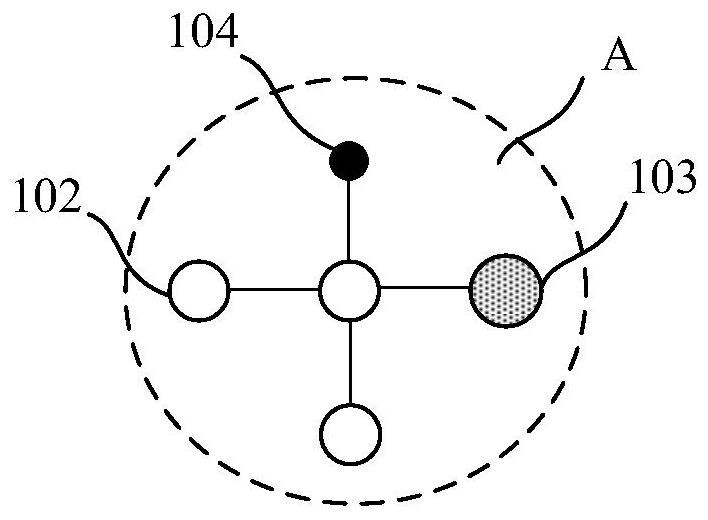

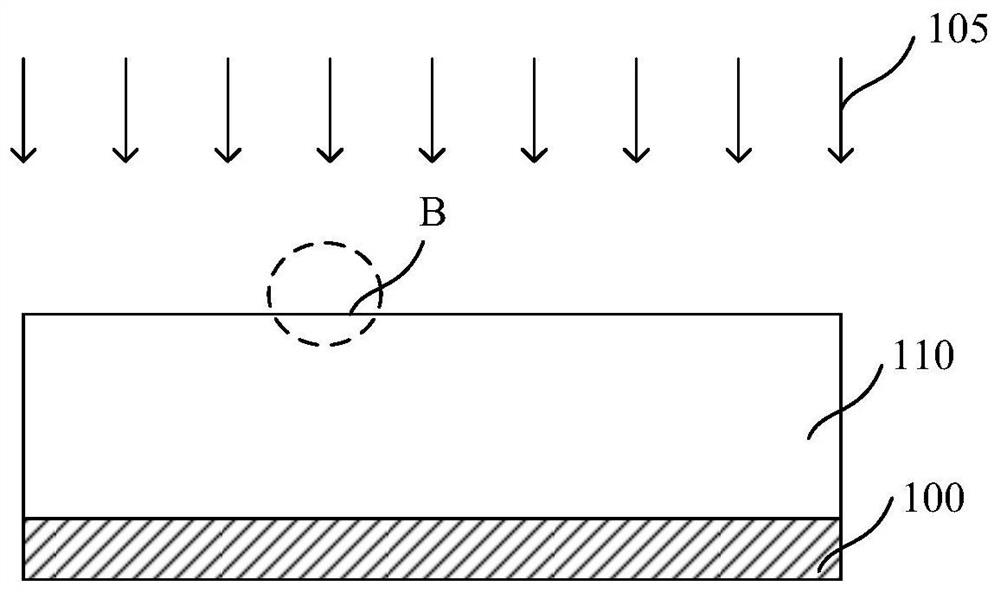

[0028] It can be seen from the background art that the performance of the film layer in the prior art is not good.

[0029] Because the diamond-like carbon film contains a large amount of hydrogen elements, the arrangement of atoms in the diamond-like carbon film is irregular, and the irregular atomic arrangement leads to the hardness of the diamond-like carbon film is not high; at the same time, because the diamond-like carbon film contains a large amount of Sp3 hybridization bonds, so the density of carbon atoms in the local area of the diamond-like film is relatively high, and the average coordination number of most atoms in the diamond-like film is relatively high, resulting in a high internal stress of the diamond-like film; When the diamond-like carbon film layer is used in the semiconductor patterning process, the diamond-like carbon film layer with relatively high internal stress has a bad influence on the transfer effect of the pattern, and easily causes warpage of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com