Fully-soluble granule and application thereof

A technology of granules and solubilizers, applied in the field of pesticides, can solve problems such as drift and omission of spraying agents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

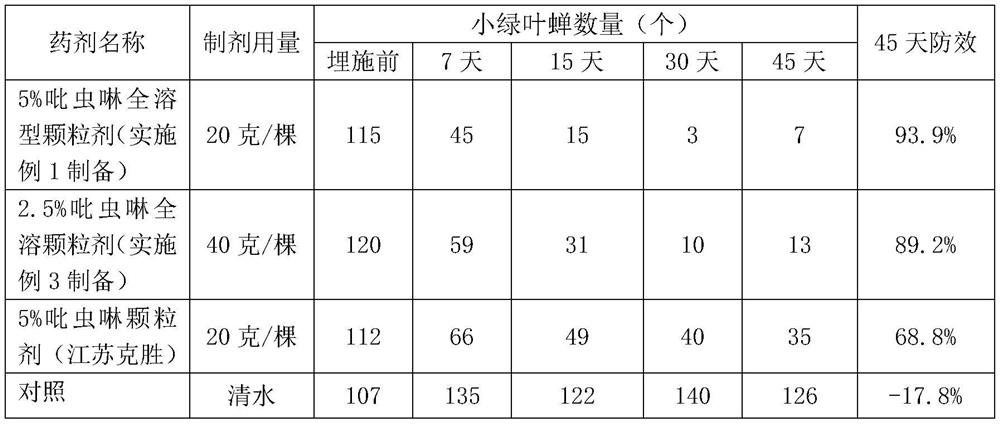

[0063] Example 1: 5% imidacloprid fully soluble granules

[0064] Pharmacy formula (by weight percentage):

[0065] 5 parts of imidacloprid (the original drug was crushed to 800 mesh)

[0066] 18 parts disintegrants (8 parts ammonium sulfate, 7 parts urea, 3 parts sodium hydroxymethylcellulose)

[0067] 19.5 parts binder (15.5% beta-cyclodextrin, 4% xanthan gum)

[0068] 9 parts excipients (glucose)

[0069] 1 part solubilizer N-methylpyrrolidone

[0070] 10 parts of dispersant morwet D-425 (manufacturer AkzoNobel)

[0071] 3.9 parts of wetting agent sodium dodecylbenzene sulfonate

[0072] 28.6 parts soluble starch

[0073] 5 parts gelatin

[0074] Preparation steps:

[0075] 1. Combine 5 parts of imidacloprid, 18 parts of disintegrant (8 parts of ammonium sulfate, 7 parts of urea, 3 parts of sodium hydroxymethyl cellulose), 9 parts of auxiliary material (glucose), 10 parts of dispersant morwet D-425, 3.9 parts of Wetting agent sodium dodecylbenzenesulfonate is weighed...

Embodiment 2

[0080] Embodiment 2: 1% imidacloprid fully soluble granules

[0081] Pharmacy formula (by weight percentage):

[0082] 1 part imidacloprid (100%, original drug crushed to 800 mesh)

[0083] 18 parts disintegrants (8 parts ammonium sulfate, 7 parts urea, 3 parts sodium hydroxymethylcellulose)

[0084] 19.5 parts binder (15.5 parts beta-cyclodextrin, 4 parts xanthan gum)

[0085] 9.6 parts excipient (glucose)

[0086] 1 part solubilizer N-methylpyrrolidone

[0087] 10 parts of dispersant morwet D-425 (manufacturer AkzoNobel)

[0088] 3.9 parts of wetting agent sodium dodecylbenzene sulfonate

[0089] 32 parts soluble starch

[0090] 5 parts gelatin

[0091] Preparation steps:

[0092] 1. Mix 1 part of imidacloprid, 18 parts of disintegrant (8 parts of ammonium sulfate, 7 parts of urea, 3 parts of sodium hydroxymethyl cellulose), 9.6 parts of auxiliary material (glucose), 10 parts of dispersant morwet D-425, 3.9 parts of dispersant Wetting agent sodium dodecyl benzene su...

Embodiment 3

[0097] Embodiment 3: 2.5% imidacloprid fully soluble granules

[0098] Pharmacy formula (by weight percentage):

[0099] 2.5 parts of imidacloprid (the original drug was crushed to 600 mesh)

[0100] 18 parts disintegrants (8 parts ammonium sulfate, 7 parts urea, 3 parts sodium hydroxymethylcellulose)

[0101] 19.5 parts binder (15.5% beta-cyclodextrin, 4% xanthan gum)

[0102] 9.5 parts excipients (sucrose)

[0103] 1 part solubilizer N-methylpyrrolidone

[0104] 10 parts of dispersant Morwet D-500 (manufacturer AkzoNobel)

[0105] 3.9 parts of wetting agent sodium dodecylbenzene sulfonate

[0106] 30.6 parts soluble starch

[0107] 5 parts gelatin

[0108] Preparation steps:

[0109] 1. Mix 2.5 parts of imidacloprid, 18 parts of disintegrant (8 parts of ammonium sulfate, 7 parts of urea, 3 parts of sodium hydroxymethyl cellulose), 9 parts of auxiliary material (glucose), 10 parts of dispersant morwet D-425, 3.9 parts of dispersant Wetting agent sodium dodecylbenzene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com