Preparation method of oxygen-free zirconium tetrafluoride applied to nuclear fission energy-- thorium-based molten salt reactor

A technology of zirconium oxytetrafluoride and molten salt reactor, which is applied in zirconium halide, nuclear power generation, reactor fuel material, etc. Easy to mix, environmentally friendly, simple raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

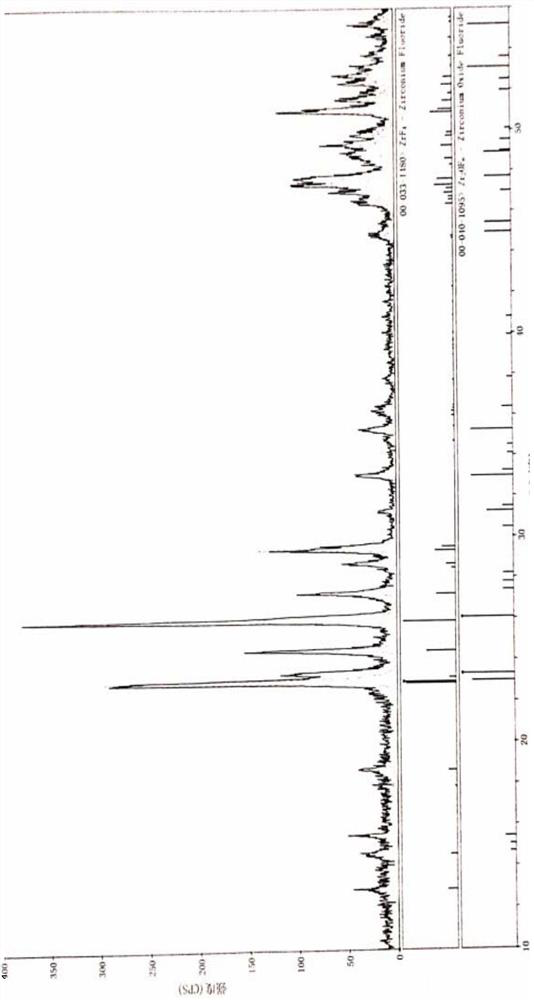

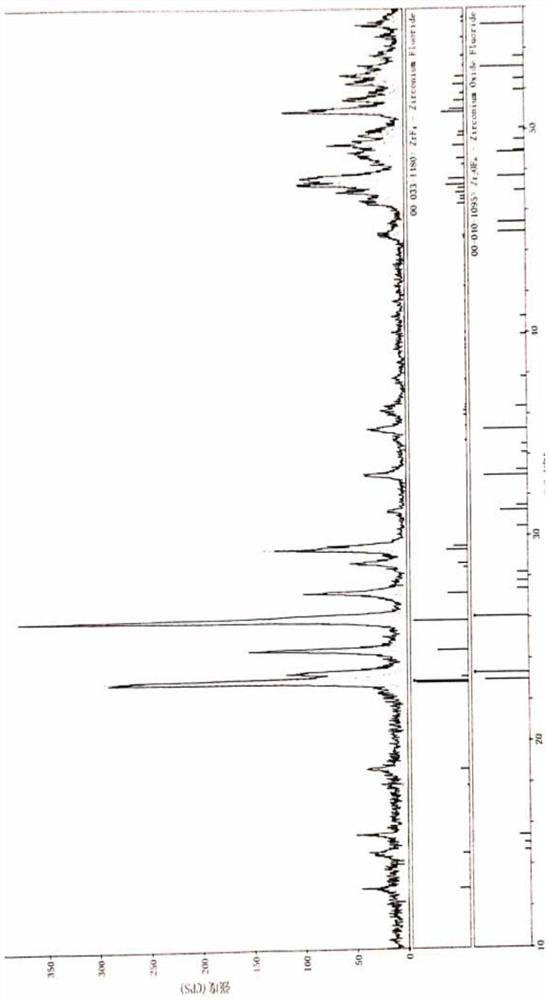

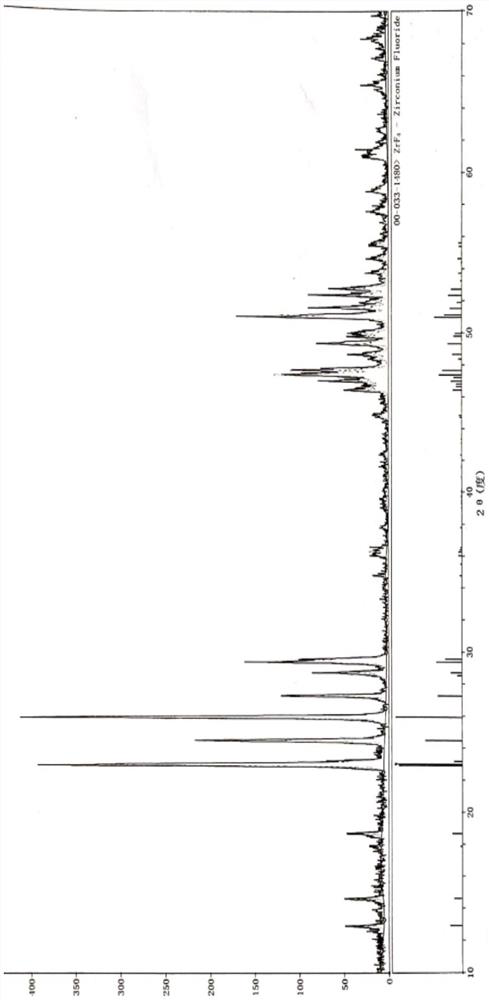

Image

Examples

Embodiment 1

[0055] This embodiment prepares oxygen-free zirconium tetrafluoride through the following steps:

[0056] Step 1, preparation of ZrF 4 .H 2 O crude product;

[0057] Step 1.1, add hydrofluoric acid with a mass concentration of 45%-50% and a mass of 3000 grams into the polytetrafluoroethylene reaction kettle, heat it to 65°C, and then quickly add it to the hydrofluoric acid at one time while stirring 750 grams of zirconium dioxide; wherein the mass ratio of the total mass of zirconium dioxide to the mass concentration of 45%-50% hydrofluoric acid is 1:2.0;

[0058] Step 1.2, wait for the reaction solution to boil, maintain the reaction temperature at 100°C, and continue the reaction for 45 minutes;

[0059] Step 1.3, add 750 grams of zirconium dioxide to the reaction solution again, keep the reaction temperature at 100°C, and continue the reaction for 40 minutes. After the reaction is complete, let it stand for 30 to 40 minutes; filter and collect the filtrate, which is ZrF ...

Embodiment 2

[0077] This example prepares oxygen-free zirconium tetrafluoride through the following steps. The difference from Example 1 is that the mass ratio of the total mass of zirconium dioxide to hydrofluoric acid with a mass concentration of 45%-50% is 1:2.2:

[0078] Step 1, preparation of ZrF 4 .H 2 O crude product;

[0079] Step 1.1, add hydrofluoric acid with a mass concentration of 45%-50% and a mass of 3000 grams into the polytetrafluoroethylene reaction kettle, heat it to 65°C, and then quickly add it to the hydrofluoric acid at one time while stirring 682 grams of zirconium dioxide; wherein the mass ratio of the total mass of zirconium dioxide to the mass concentration of 45%-50% hydrofluoric acid is 1:2.2;

[0080] Step 1.2, wait for the reaction solution to boil, maintain the reaction temperature at 100°C, and continue the reaction for 45 minutes;

[0081] Step 1.3, add 682 grams of zirconium dioxide to the reaction solution again, keep the reaction temperature at 100°C...

Embodiment 3

[0097] This example prepares oxygen-free zirconium tetrafluoride through the following steps. The difference from Example 1 is that the mass ratio of the total mass of zirconium dioxide to hydrofluoric acid with a mass concentration of 45%-50% is 1:1.8:

[0098] Step 1, preparation of ZrF 4 .H 2 O crude product;

[0099] Step 1.1, add hydrofluoric acid with a mass concentration of 45%-50% and a mass of 3000 grams into the polytetrafluoroethylene reaction kettle, heat it to 65°C, and then quickly add it to the hydrofluoric acid at one time while stirring 833 grams of zirconium dioxide; wherein the mass ratio of the total mass of zirconium dioxide to the mass concentration of 45%-50% hydrofluoric acid is 1:1.8;

[0100] Step 1.2, wait for the reaction solution to boil, maintain the reaction temperature at 100°C, and continue the reaction for 45 minutes;

[0101] Step 1.3, add 833 grams of zirconium dioxide to the reaction solution again, keep the reaction temperature at 100°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com