A method for recycling photovoltaic fluorine-containing wastewater

A recycling and waste water technology, applied in chemical instruments and methods, calcium/strontium/barium fluoride, water pollutants, etc., can solve problems such as waste, residual lime residue, solid waste fluorine resources, etc., and achieve increased utilization High efficiency, improved quality, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

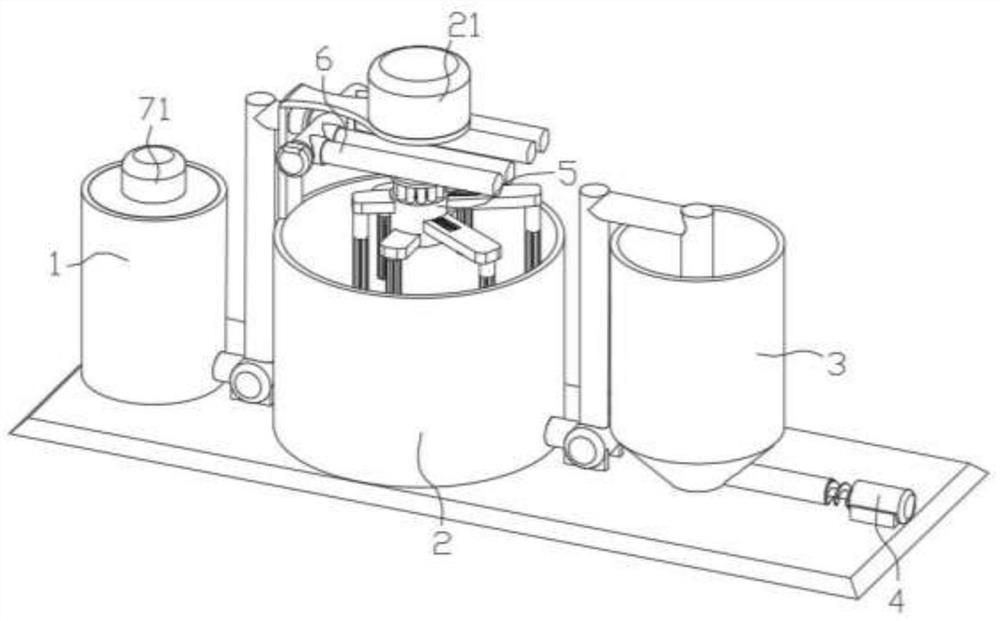

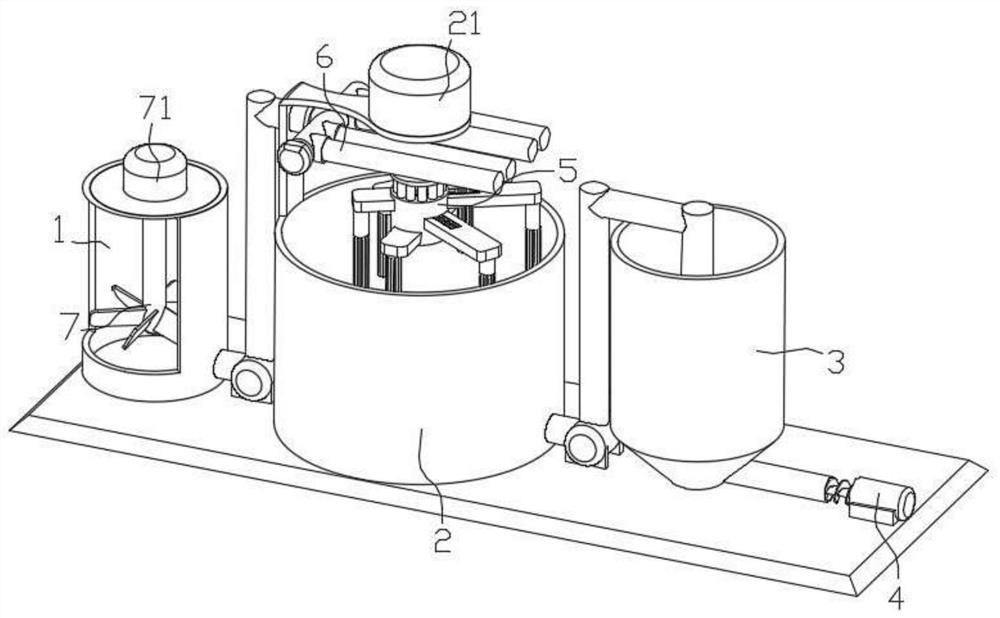

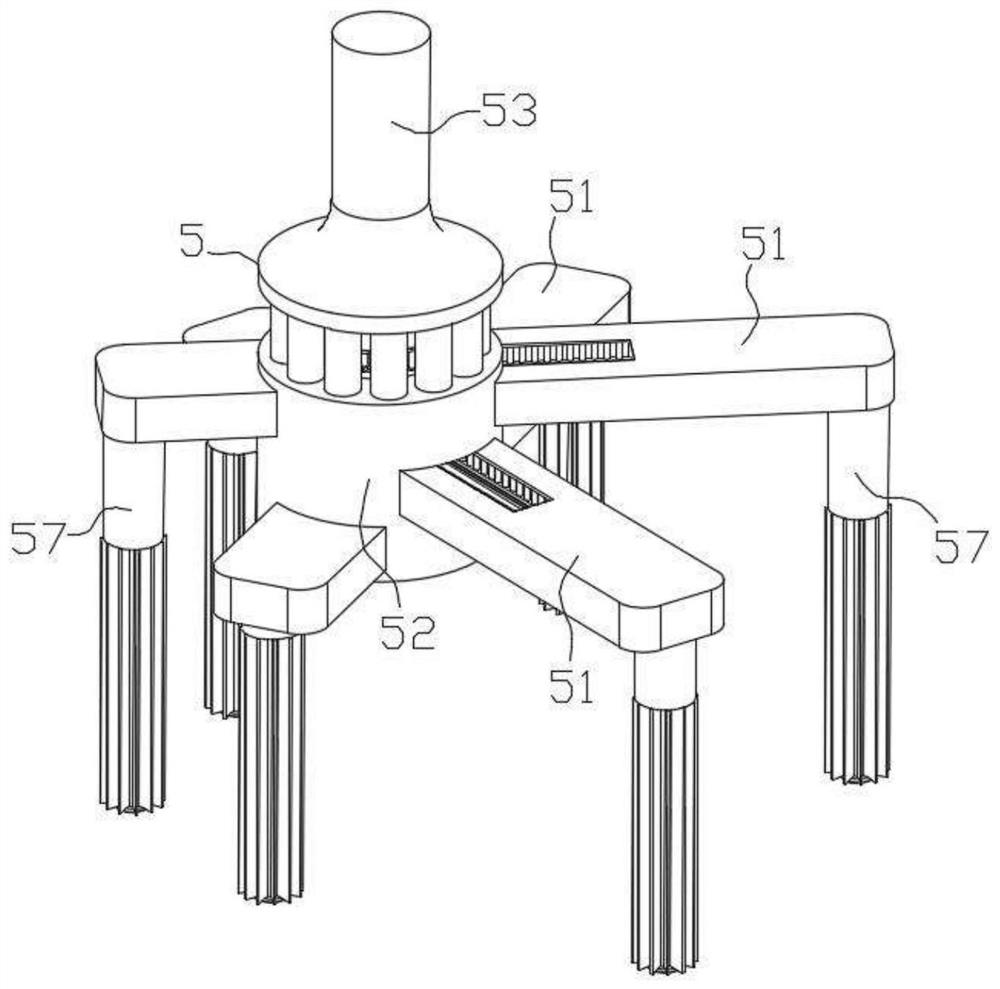

Image

Examples

Embodiment 1

[0044] S1: Configure the calcium chloride reaction solution for the reaction and treatment of photovoltaic fluorine-containing wastewater through the calcium chloride configuration tank, and wait for use; the preparation of the calcium chloride reaction solution is 74.5g / 100mL saturated calcium chloride solution;

[0045] S2: The calcium chloride reaction solution is added dropwise to the reaction pool in multiple points for mixed reaction with the photovoltaic fluorine-containing wastewater under acidic conditions of pH=1~2, and the dosage of the calcium chloride reaction solution is according to Ca:F=1: The molar ratio of 2 is added, and the stirring speed is 500rpm to obtain the reaction mixture; the calcium fluoride seed crystals accounting for 15g / L of photovoltaic fluorine-containing wastewater injection are also added in the calcium chloride reaction solution; by adding the above-mentioned dosage The strong agent can effectively promote the output of calcium fluoride pre...

Embodiment 2

[0048] This example is basically the same as Example 1, except that the stirring speed of the calcium chloride reaction liquid and photovoltaic fluorine-containing wastewater is different when they are mixed dropwise, specifically as follows: the stirring speed is 200 rpm.

Embodiment 3

[0050] This example is basically the same as Example 1, except that the stirring speed of the calcium chloride reaction liquid and photovoltaic fluorine-containing wastewater is different when they are mixed dropwise, specifically as follows: the stirring speed is 1000 rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com