Composite biochar and preparation method thereof, and ecological restoration method of industrial solid waste

A technology of biochar and solid water, applied in fertilizer mixtures, chemical instruments and methods, agriculture, etc., can solve problems such as pH reduction and difficulty in stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

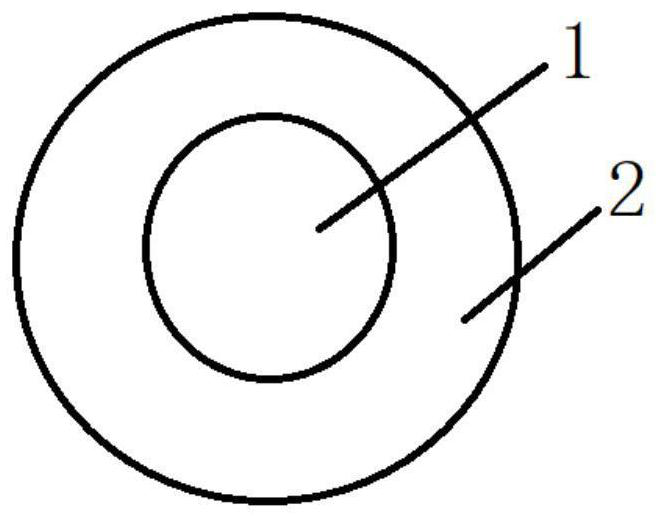

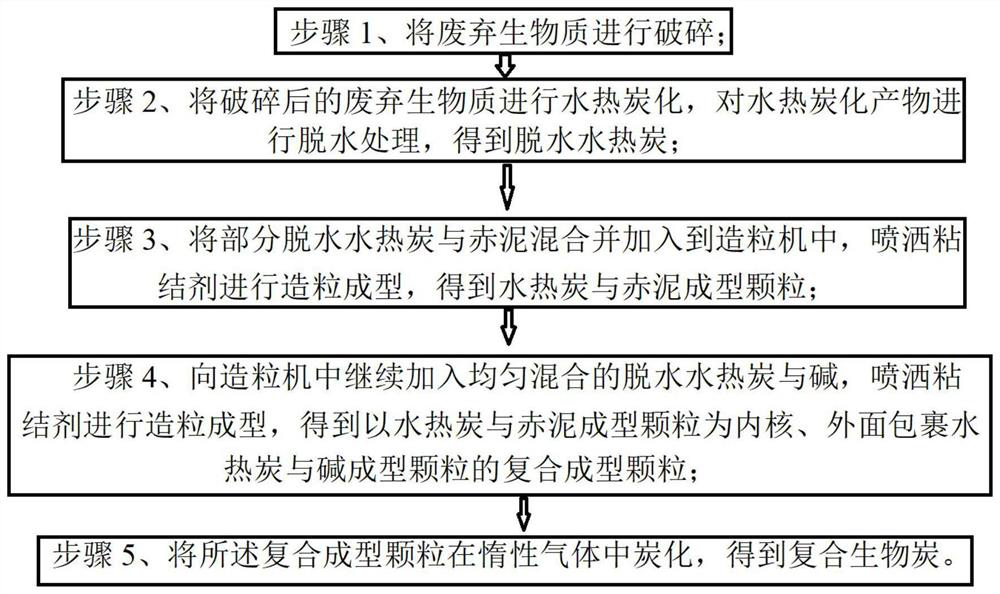

[0047] On the other hand, the present invention also provides a preparation method of composite biochar, such as figure 2 shown, including the following steps:

[0048] Step 1, crushing the waste biomass;

[0049] Step 2, subjecting the broken waste biomass to hydrothermal carbonization, separating the hydrothermal carbonization product from solid and liquid to obtain solid hydrothermal charcoal, and dehydrating the solid hydrothermal charcoal to obtain dehydrated hydrothermal charcoal;

[0050] Step 3, mix part of the dehydrated hydrothermal charcoal and red mud evenly, then add it to the granulator, spray the binder to granulate and form, and obtain hydrothermal charcoal and red mud shaped granules;

[0051] Step 4. Continue to add evenly mixed dehydrated hydrothermal charcoal and alkali to the granulator, spray the binder for granulation and molding, and obtain hydrothermal charcoal and red mud shaped particles as the core, and the outer surface is wrapped with hydrotherm...

Embodiment 1

[0074] The present embodiment provides a kind of preparation method of composite biochar, comprising the following steps:

[0075] Step 1, crushing the lignocellulosic biomass; the mass content of lignin, cellulose, and hemicellulose in the lignocellulosic biomass is 54%; the particle size of the waste biomass after crushing is 0.18mm; the lignocellulose Examples of biomass include straw, wood chips, fallen leaves, bagasse and coconut shells.

[0076] Step 2. Carry out hydrothermal carbonization of the waste biomass after crushing, and add citric acid with a mass concentration of 2% during hydrothermal carbonization; during the hydrothermal carbonization process, the mass ratio of waste biomass to water is 1:1; The carbonization temperature is 155°C, and the hydrothermal carbonization time is 32 minutes; the hydrothermal carbonization product is subjected to solid-liquid separation to obtain solid hydrothermal charcoal, and the solid hydrothermal charcoal is dehydrated. The wa...

Embodiment 2

[0081] The present embodiment provides a kind of preparation method of composite biochar, comprising the following steps:

[0082] Step 1, crushing the lignocellulosic biomass; the mass content of lignin, cellulose, and hemicellulose in the lignocellulosic biomass is 70%; the particle size of the waste biomass after crushing is 0.15 mm; the lignocellulose Examples of biomass include straw, wood chips, fallen leaves, bagasse and coconut shells.

[0083] Step 2. Carrying out hydrothermal carbonization of the crushed waste biomass, adding oxalic acid with a mass concentration of 5% during hydrothermal carbonization; during the hydrothermal carbonization process, the mass ratio of waste biomass to water is 1:3; hydrothermal carbonization The temperature is 200°C, and the hydrothermal carbonization time is 170 minutes; the hydrothermal carbonization product is subjected to solid-liquid separation to obtain solid hydrothermal charcoal, and the solid hydrothermal charcoal is dehydrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com