Method for recycling colored polyester fabric

A polyester fabric and colored polyester technology, applied in the field of waste fabric resource utilization, can solve the problems of equipment protection, high water consumption, high energy consumption, etc., and achieve the effects of small strength loss, small water consumption, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

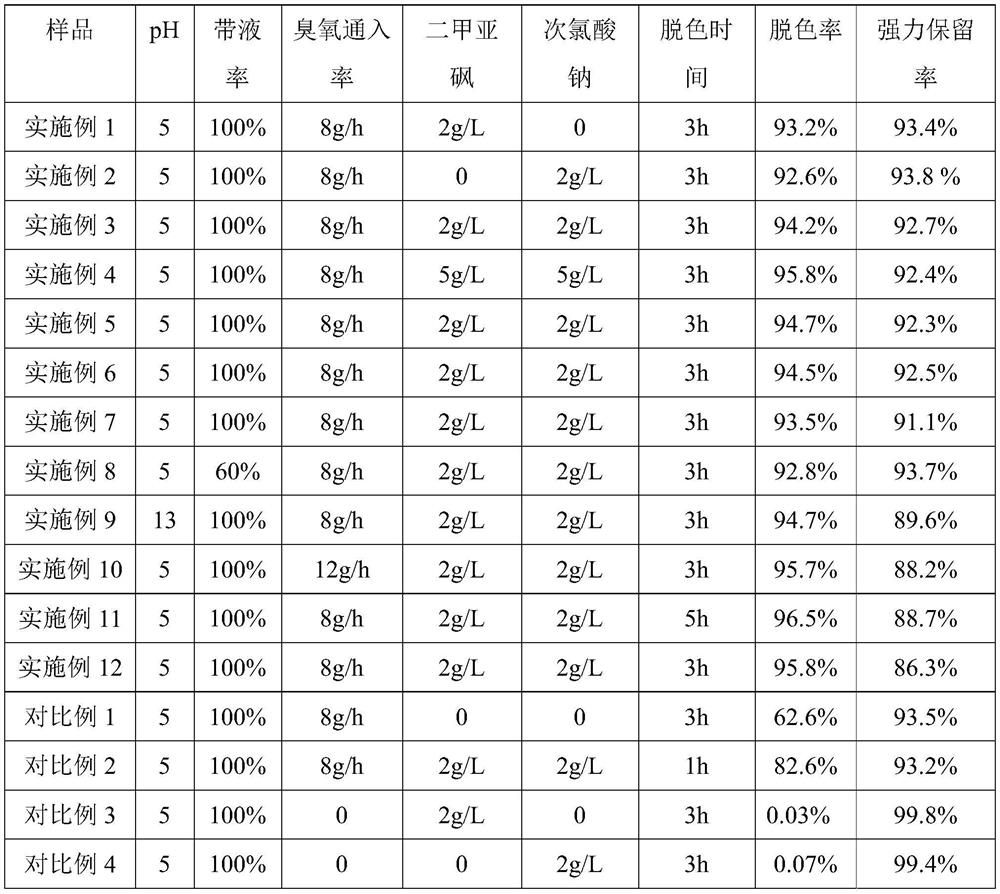

Examples

Embodiment 1

[0043] Decolorized as is: Polyester knitted fabric dyed with C.I. Disperse Red 167 at 2% o.w.f.

[0044] The following methods are used to decolorize colored polyester fabrics:

[0045] (1) Liquefaction process: the dyed polyester fabric is immersed in a 2 g / L dimethyl sulfoxide solution with a pH of 5, and the liquid is squeezed to make the liquid retention rate 100%.

[0046] (2) Decolorization process: put a fabric with a certain liquid rate in the reactor, ozone is input from one end, and tail gas is output from the other end. The ozone inflow rate in the reactor is controlled to 8g / h, and the treatment temperature is 25°C. The time is 3h.

[0047] (3) Post-treatment process: take out the fabric after decolorization, wash 3 times with water at a water temperature of 50°C, and dry.

[0048] The color change of the colored polyester cloth treated by this method is obvious, and the K / S value before and after decolorization is measured with a Datacolor color measuring instru...

Embodiment 2

[0050] Decolorized as is: Polyester knitted fabric dyed with C.I. Disperse Red 167 at 2% o.w.f.

[0051] The following methods are used to decolorize colored polyester fabrics:

[0052] (1) Liquefaction process: the dyed polyester fabric is immersed in a 2 g / L sodium hypochlorite solution with a pH of 5, and the liquification is carried out so that the liquid retention rate is 100%.

[0053] (2) Decolorization process: put a fabric with a certain liquid rate in the reactor, ozone is input from one end, and tail gas is output from the other end. The ozone inflow rate in the reactor is controlled to 8g / h, and the treatment temperature is 25°C. The time is 3h.

[0054] (3) Post-treatment process: take out the fabric after decolorization, wash 3 times with water at a water temperature of 50°C, and dry.

[0055] The color change of the colored polyester fabric treated by this method is obvious, and the K / S value and the bursting strength value of the polyester fabric of this embo...

Embodiment 3

[0057] Decolorized as is: Polyester knitted fabric dyed with C.I. Disperse Red 167 at 2% o.w.f.

[0058] The following methods are used to decolorize colored polyester fabrics:

[0059] (1) Liquefaction process: the dyed polyester fabric is immersed in a mixed solution of 2 g / L dimethyl sulfoxide and sodium hypochlorite with a pH of 5, and the liquid is squeezed to make the liquid retention rate 100%. The dimethyl sulfoxide in the mixed solution The mass ratio to sodium hypochlorite is 1:1.

[0060] (2) Decolorization process: put a fabric with a certain liquid rate in the reactor, ozone is input from one end, and tail gas is output from the other end. The ozone inflow rate in the reactor is controlled to 8g / h, and the treatment temperature is 25°C. The time is 3h.

[0061] (3) Post-treatment process: take out the fabric after decolorization, wash 3 times with water at a water temperature of 50°C, and dry.

[0062] The color change of the colored polyester fabric treated by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com