High-crack-resistance anti-corrosion reinforced concrete drainage pipe and production process thereof

A technology for reinforced concrete and concrete pipes, which is applied in the direction of anti-corrosion/anti-rust protection of pipes, pipes, and pipe components, and can solve the problems of water flow disturbance of concrete pipes, corrosion of concrete pipes, and additions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

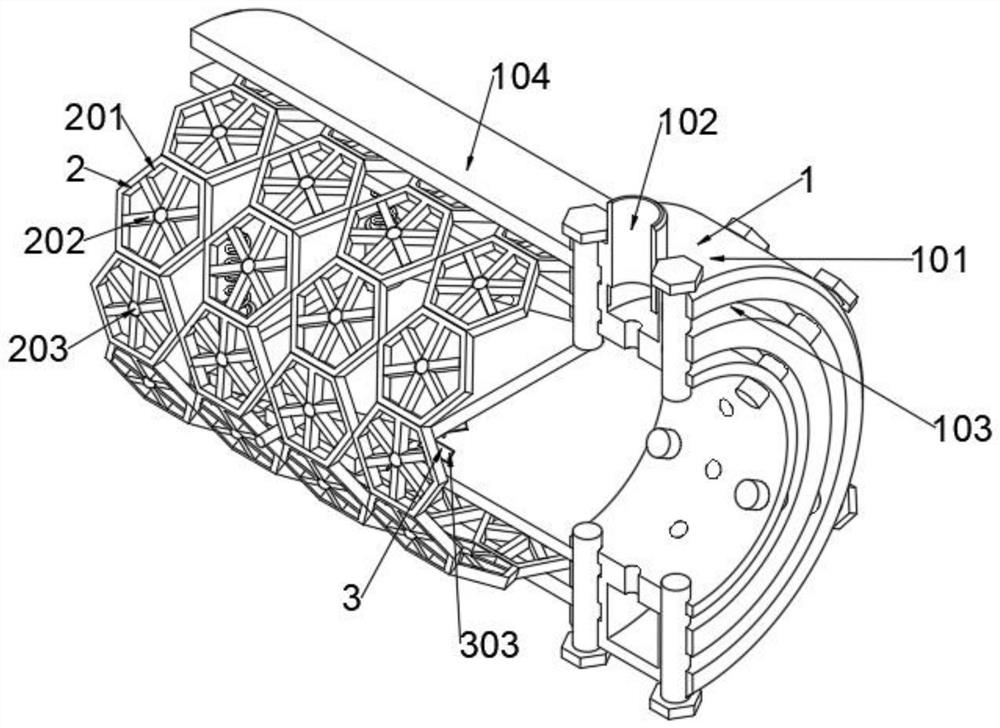

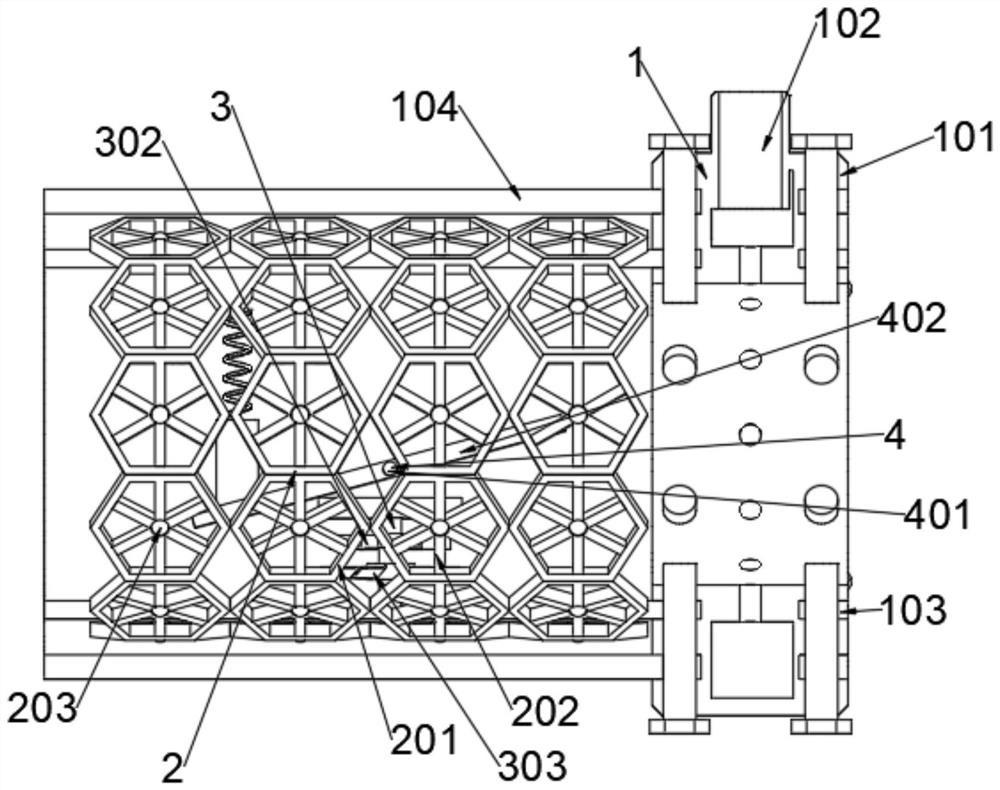

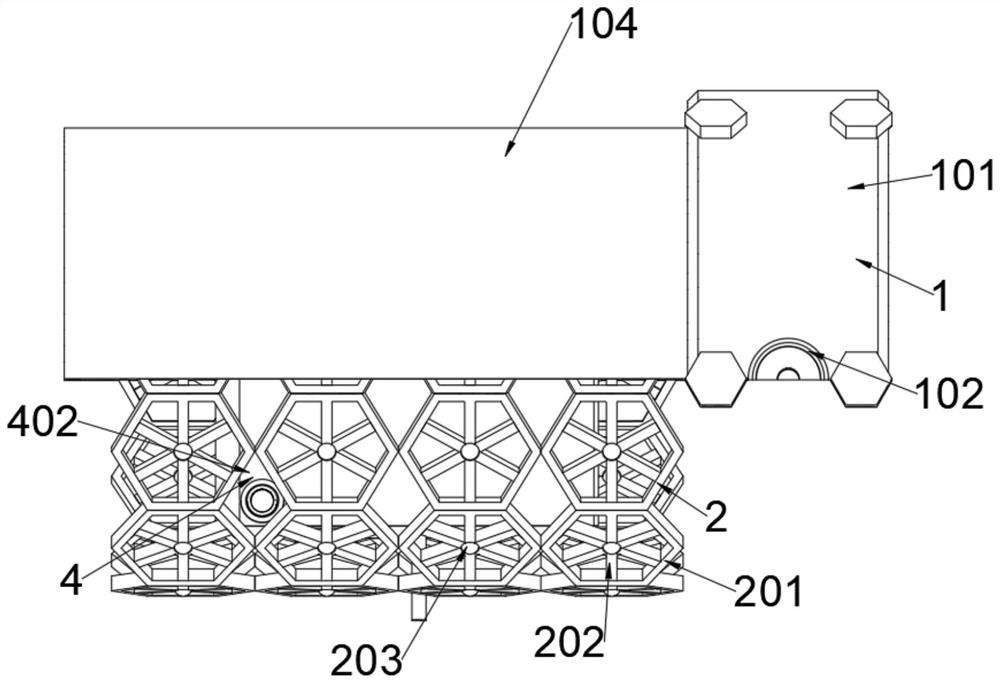

[0040] as attached figure 1 To attach Figure 8 Shown:

[0041] The invention provides a highly crack-resistant anti-corrosion reinforced concrete drainage pipe and its production process, including: an anti-crack mechanism 2 and an anti-blocking mechanism 3, the anti-crack mechanism 2 is installed in an inner position of the bearing mechanism 1 in an annular array; the anti-blocking mechanism The mechanism 3 is installed on the inner left side of the carrying mechanism 1, and a spoiler mechanism 4 is installed directly above the anti-blocking mechanism 3; the spoiler mechanism 4 also includes a side column 403 and a traction spring 404, and the side column 403 is provided with two , and the two side columns 403 are designed with a hollow cylindrical structure, and the two side columns 403 are installed on the left and right sides of the top surface of the shutter 402 respectively, and traction springs are installed inside the two side columns 403 404.

[0042] Wherein, the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap