Flexible porous graphene film electrode, preparation method thereof and application of flexible porous graphene film electrode in flexible energy storage

A graphene film, graphene technology, applied in cable/conductor manufacturing, hybrid capacitor electrodes, circuits, etc., can solve problems such as slow ion transmission and poor electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

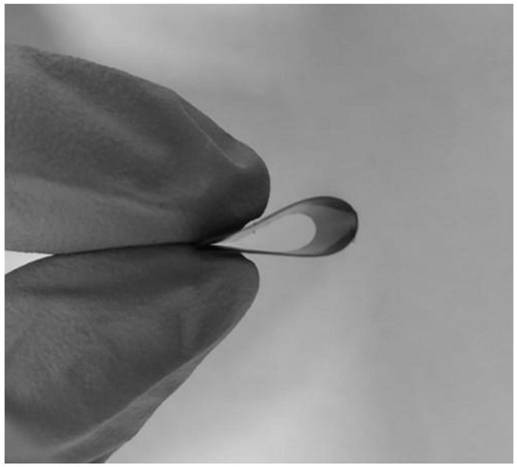

[0075] The invention provides a kind of preparation method of graphene composite film, comprises the following steps:

[0076] 1) After mixing the conductive polymer aqueous solution and the organic solvent, a mixed solution is obtained, and then graphene is added and mixed again to obtain a slurry;

[0077] 2) The slurry obtained in the above steps is formed into a film, and then annealed to obtain a graphene composite film.

[0078] In the invention, firstly, the conductive polymer aqueous solution and the organic solvent are mixed to obtain a mixed solution, and then graphene is added and mixed again to obtain a slurry.

[0079] In the present invention, the conductive polymer preferably includes poly(3,4-ethylenedioxythiophene)-polystyrenesulfonic acid (PEDOT:PSS). Specifically, it can be PEDOT:PSS500(PH500), PEDOT:PSS1000(PH1000) and PEDOT:PSS4083(PH4083) in the (PEDOT:PSS) series.

[0080] In the present invention, the organic solvent preferably includes one or more of...

Embodiment

[0117] (1) Selection of materials

[0118] Select commercially available highly conductive graphene powder, conductive polymer aqueous solution PH1000, and organic solvent DMSO.

[0119] (2) Preparation of slurry

[0120] 1) Add DMSO into water, and make a homogeneous solution through ultrasonication (sink type ultrasonic machine) for 5-10 minutes, wherein the proportion of DMSO is selected as 10% (accounting for the final solution).

[0121] 2) Add PH1000 aqueous solution, and undergo ultrasonication (cell crushing ultrasonic machine, 1000W, 1min; sink type ultrasonic machine for 15min), so that the entangled polymer chains of PH1000 are stretched out.

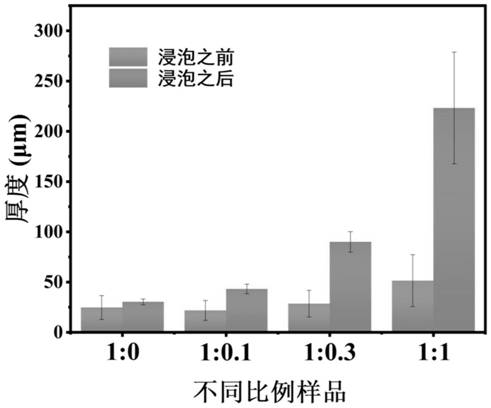

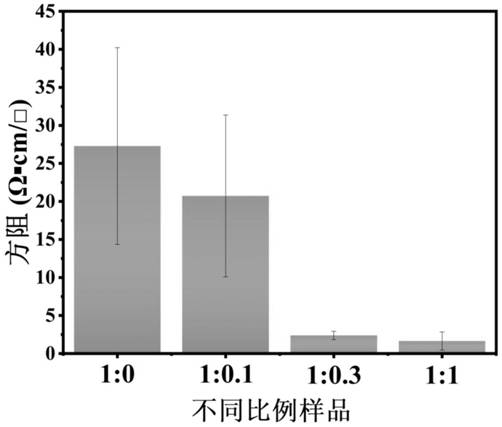

[0122] 3) Add graphene powder to the above solution, so that the mass ratio of graphene to PH1000 is 1:0 (comparison), 1:0.1, 1:0.3, 1:1. Further ultrasonic treatment (cell crushing ultrasonic machine, 1000W, 1min; sink type ultrasonic machine 30min), makes PH1000 fully self-assemble on the graphene surface.

[0123] (3) F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com