Silver powder for 5G filter and production method thereof

A production method and filter technology, which are applied in metal processing equipment, transportation and packaging, etc., can solve the problems of sintering active shrinkage rate, silver ion mobility, low weldability, lack of self-production ability, etc., and improve the density. And the effect of electrical conductivity, high adhesion and excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A 5G filter is silver powder, which includes the following components: 20 parts of spherical silver powder by weight. Among them, the particle size of spherical silver powder is 0.1-2 μm.

[0037] It should be noted that the spherical silver powder includes two silver powder of different particle diameters, and a silver powder has a particle diameter of 0.1 μm, and the diameter of the silver powder is 0.8 μm. The silver powder used in the particle diameter of 0.1 μm accounted for 10% of the total spherical silver powder, and thus the spherical silver powder and the sheet-like silver powder were effectively filled. At the same time, the spherical silver powder employed is prepared from the raw silver powder.

[0038] The production method of silver powder for the 5G filter of the present embodiment includes the following steps:

[0039] Step 1, a spherical silver powder having a particle diameter of 0.1 μm is 1: 9 by weight, and the particle size is 0.8 μm spherical silver p...

Embodiment 2

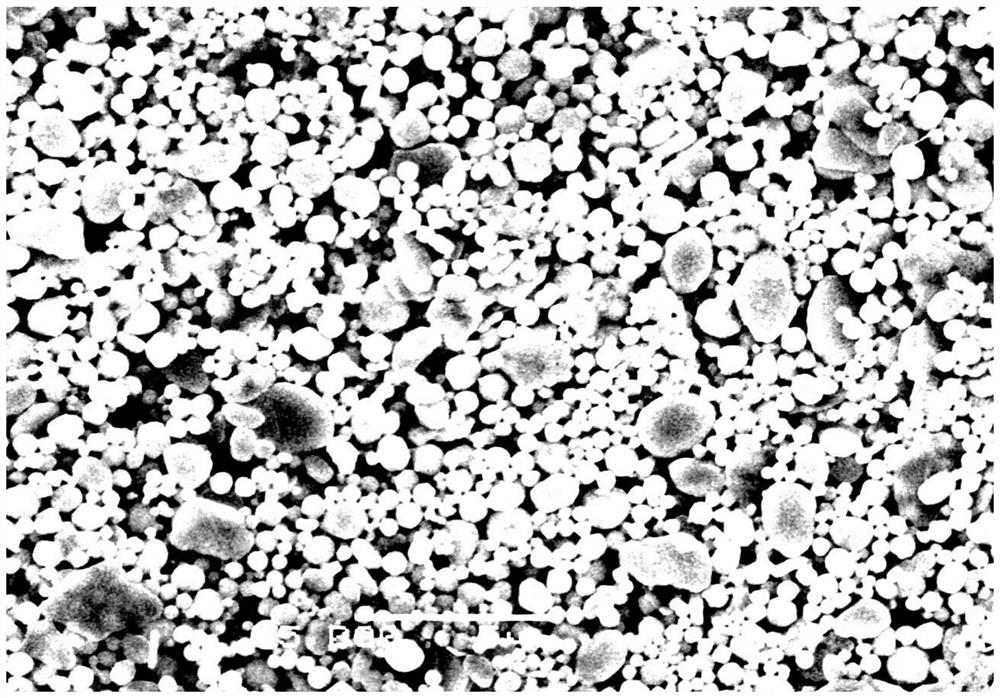

[0045] Such as figure 1 As shown, a 5G filter is silver powder, which includes the following components: 64 pieces of spherical silver powder and 80 parts of silver powder. Among them, the particle diameter of the spherical silver powder is 0.1-2 μm, the sheet length of the sheet silver powder is 5 μm, and the film thickness is 0.5 μm.

[0046] It should be noted that the spherical silver powder includes two silver powder of different particle diameters, and a silver powder has a particle diameter of 0.3 μm, and the particle diameter of the silver powder is 1.4 μm. The silver powder used in the particle size of 0.3 μm accounted for 12.5% of the total spherical silver powder, and thus effectively fill the spherical silver powder and sheet silver powder. At the same time, the spherical silver powder employed is prepared from the raw silver powder.

[0047] The production method of silver powder for the 5G filter of the present embodiment includes the following steps:

[0048] Step 1...

Embodiment 3

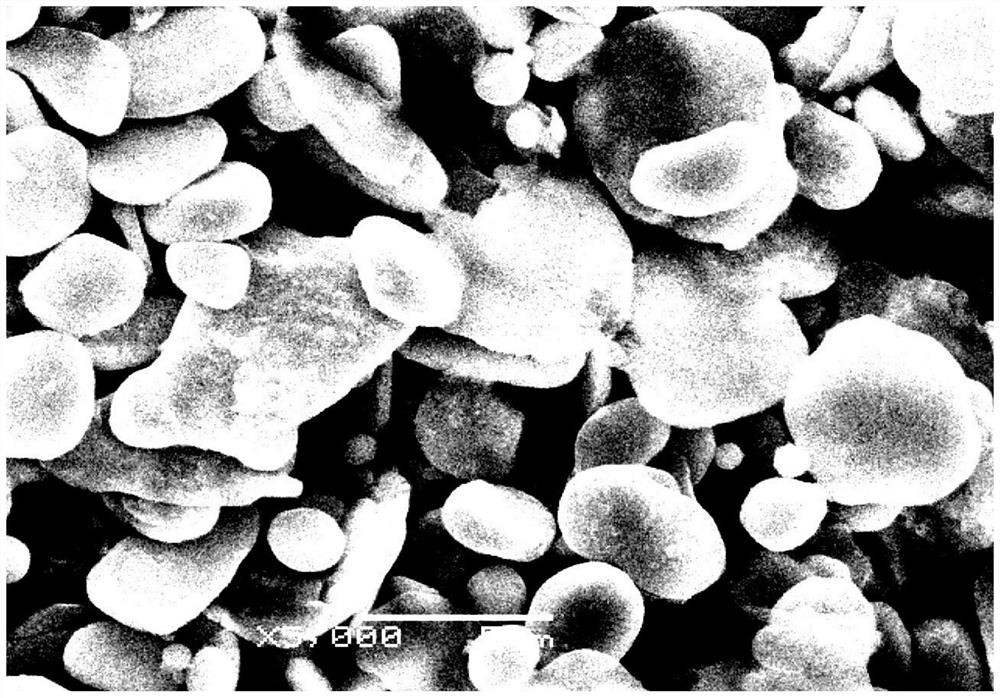

[0054] Such as figure 2 As shown, a 5G filter is silver powder, which includes the following components: 80 parts of spherical silver powder and 80 parts of sheet-like silver powder. Among them, the particle size of the spherical silver powder is 0.1-2 μm, and the sheet length of the sheet silver powder is 10 μm, and the film thickness is 1.0 μm.

[0055] It should be noted that the spherical silver powder includes two different particle diameter silver powder, and a silver powder has a particle diameter of 0.5 μm, and the diameter of the silver powder is 2 μm. The silver powder used in the particle size of 0.5 μm accounted for 20% of the total weight of the spherical silver powder, and thus the spherical silver powder and the sheet-like silver powder were effectively filled. At the same time, the spherical silver powder employed is prepared from the raw silver powder.

[0056] The production method of silver powder for the 5G filter of the present embodiment includes the followin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com